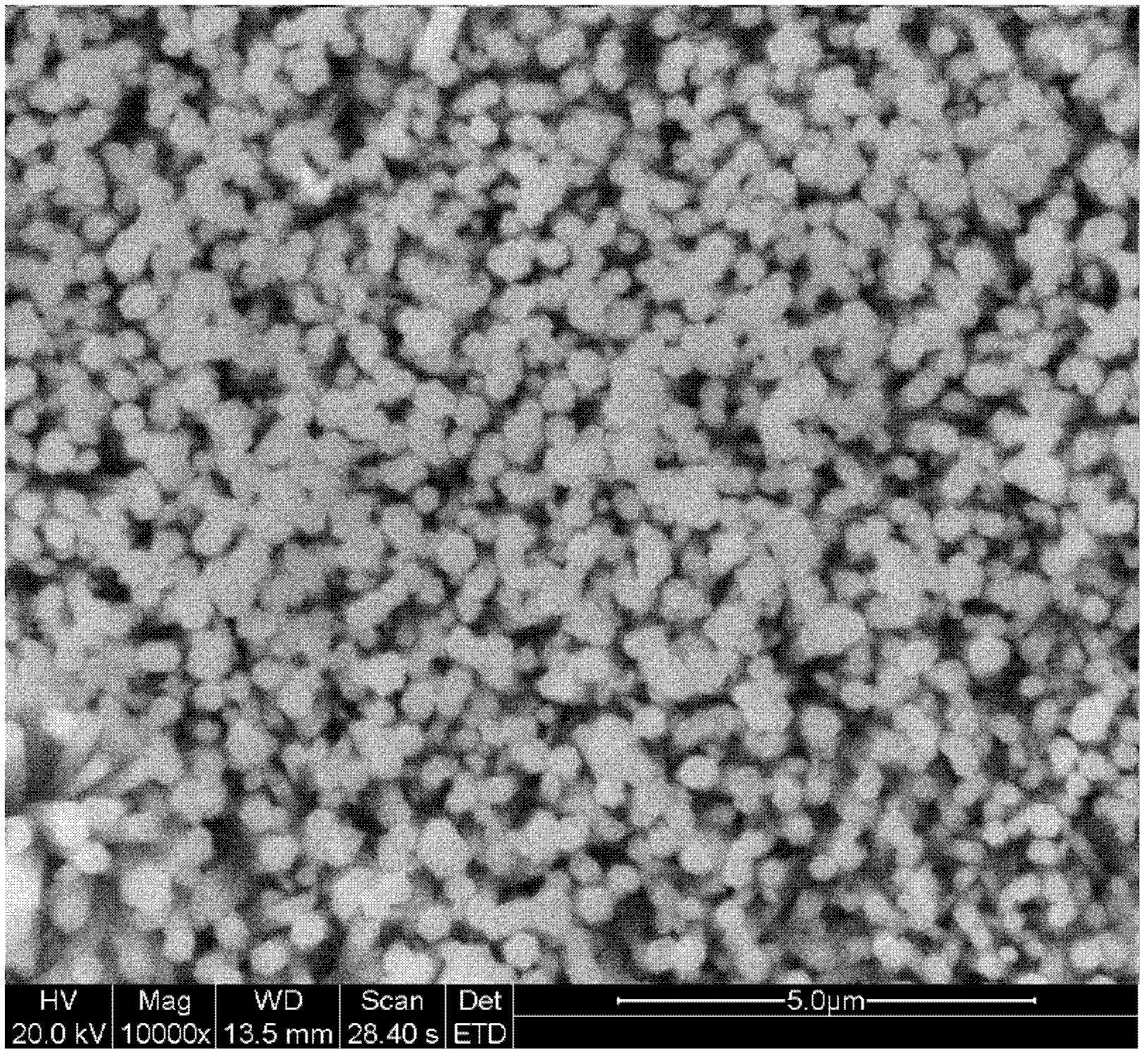

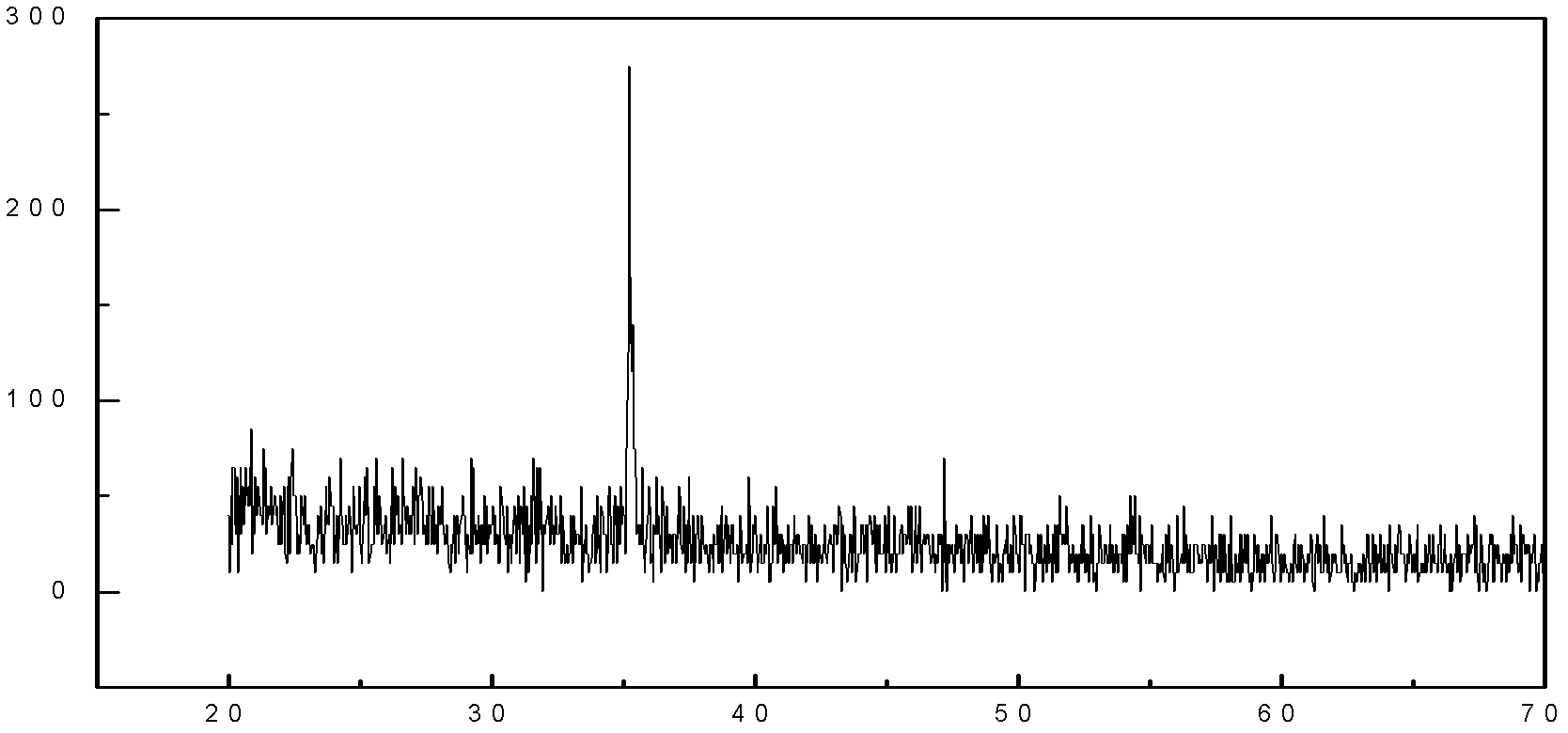

Process for growth of ZnO nano-wire array on flexible substrate by using solution method

A nanowire array and flexible substrate technology, which is applied in the field of solution growth of ZnO nanowire arrays on flexible substrates, can solve the problems of expensive process conditions, unsuitable for low-cost preparation of ZnO nanowire arrays, and achieves growth orientation. Good, low cost, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The PI film was treated in an 8% NaOH aqueous solution for 10 minutes, and then the treated PI film was soaked in a 10% HCl solution for 5 minutes, washed with water three times, and then vacuum-dried for 12 hours.

[0036] The acid-base treated PI film was washed with detergent, rinsed with distilled water, ultrasonicated in acetone and ethanol for 15 minutes, rinsed with deionized water, and dried for later use.

[0037] Weigh a certain amount of zinc acetate dihydrate in a beaker, and then dropwise add the stabilizer monoethanolamine with the amount of zinc acetate dihydrate and other substances with a dropper, and monoethanolamine will combine with Zn 2+ Combine in a 1:1 ratio. Then add a certain amount of ethylene glycol methyl ether to configure Zn 2+ A mixed solution with a concentration of 0.3mol / L. Place the beaker in a water bath at 75°C and stir for 3 hours to form a yellowish transparent sol. Take out the beaker and dry it, put it in a desiccator and let ...

Embodiment 2

[0041] The PI film was treated in 5% KOH aqueous solution for 40 minutes, and then the treated PI film was soaked in 5% hydrogen sulfuric acid solution for 40 minutes, washed with water three times, and then vacuum-dried for 12 hours.

[0042] The acid-base treated PI film was washed with detergent, rinsed with distilled water, ultrasonicated in acetone and ethanol for 15 minutes, rinsed with deionized water, and dried for later use.

[0043] Weigh a certain amount of zinc acetate dihydrate in a beaker, and then dropwise add the stabilizer monoethanolamine with the amount of zinc acetate dihydrate and other substances with a dropper, and monoethanolamine will combine with Zn 2+ Combine in a 1:1 ratio. Then add a certain amount of ethylene glycol methyl ether to configure Zn 2+ A mixed solution with a concentration of 0.2mol / L. Place the beaker in a 60°C water bath with stirring and heating for 6 hours to form a light yellow transparent sol. Take out the beaker and dry it, p...

Embodiment 3

[0046] The PI thin film in the mass fraction of 20% Ba(OH) 2 Treat in aqueous solution for 2 minutes, then soak the treated PI film in sulfuric acid solution with a mass fraction of 20% for 2 minutes, wash with water for 3 times, and then vacuum dry for 12 hours.

[0047] The acid-base treated PI film was washed with detergent, rinsed with distilled water, ultrasonicated in acetone and ethanol for 15 minutes, rinsed with deionized water, and dried for later use.

[0048] Weigh a certain amount of zinc nitrate in a beaker, and then dropwise add the stabilizer diethanolamine with the amount of zinc nitrate and other substances with a dropper, and diethanolamine will combine with Zn 2+ Combine in a 1:1 ratio. Then add a certain amount of isopropanol to configure Zn 2+ A mixed solution with a concentration of 0.6mol / L. Place the beaker in an 80°C water bath with stirring and heating for 1 hour to form a light yellow transparent sol. Take out the beaker and wipe it dry, put it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com