Carbon coated ZnO nanowire, and preparation method and application thereof

A nanowire, carbon-coated technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of shortening battery life, producing zinc dendrites, and deforming zinc electrodes. Effects of avoiding the use of binders, good mechanical properties, excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

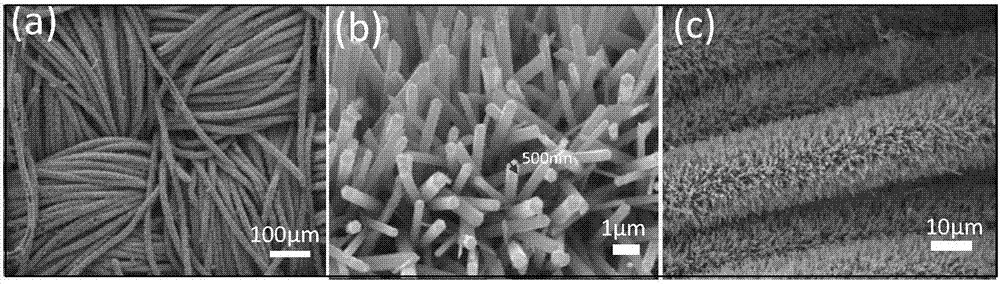

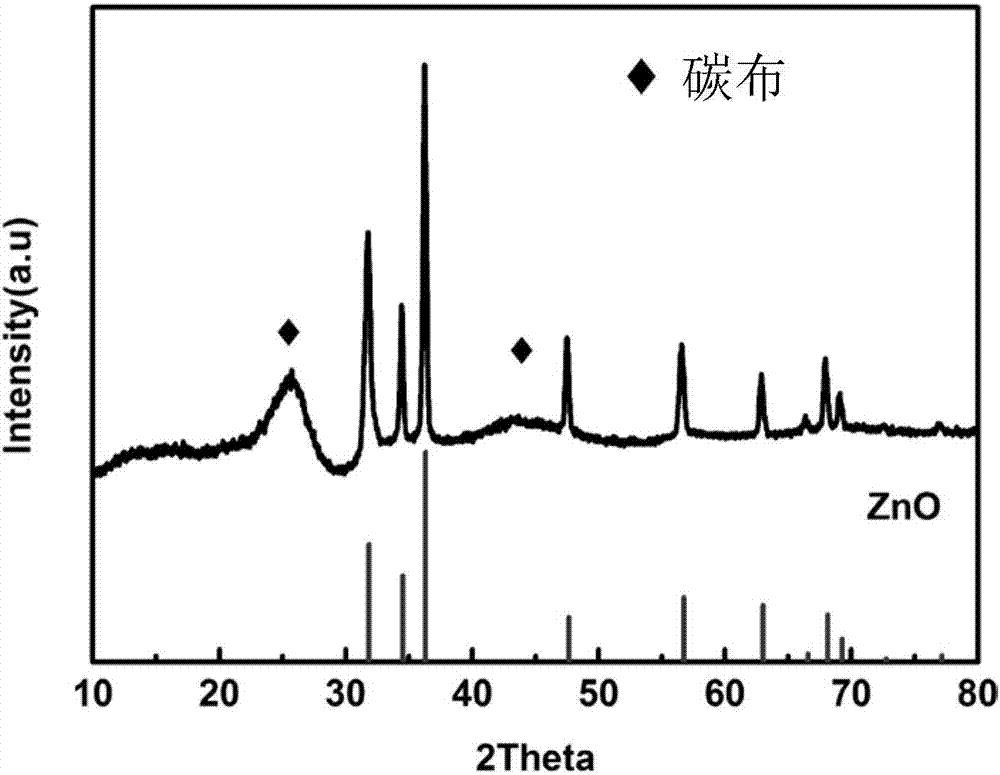

[0040] A preparation method for carbon-coated zinc oxide connecting nanowire material, which comprises the following steps:

[0041] 1) 10.5mmol hexamethylenetetramine, 10.5mmol Zn(NO 3 ) 3 ·6H 2 O was added to 50.0mL deionized water, and magnetically stirred at 25°C to dissolve it completely, forming a uniform and transparent solution.

[0042] 2) Add 5.25ml of ammonia water dropwise to the solution obtained in step 1), stir while adding, and adjust the pH to 10,

[0043] 3) Transfer the solution obtained in step 2) into a 100ml reaction kettle, and put in a 3*3cm 2 carbon cloth,

[0044] 4) Put the reaction kettle into an oven at 90°C, keep it warm for 24 hours, take out the carbon cloth, rinse it repeatedly with deionized water and alcohol, and then put it in an oven at 70°C for one night.

[0045] 5) Put the carbon cloth obtained in step 4) into a glass dish, spread a certain amount of dimethylimidazole on the bottom of the glass dish, cover and seal the reaction dish...

Embodiment 2

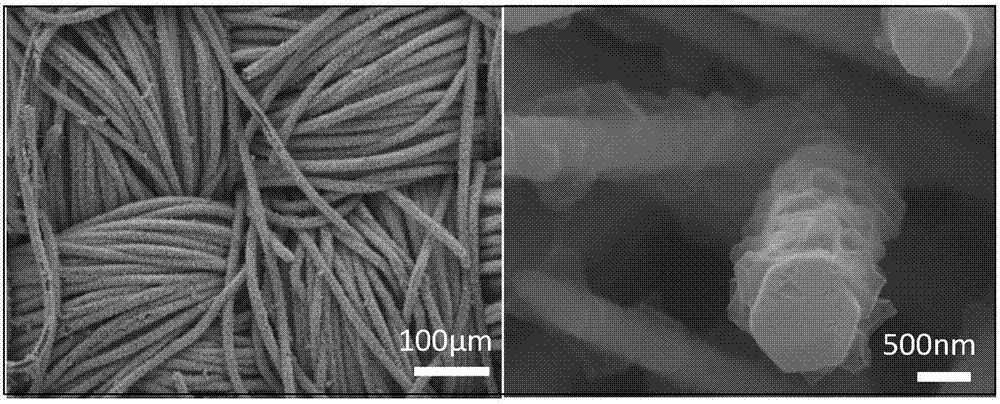

[0055] A preparation method for carbon-coated zinc oxide connecting nanowire material, which comprises the following steps:

[0056] 1) 15mmol hexamethylenetetramine, 15mmol Zn(NO 3 ) 3 ·6H 2 O was added to 50.0mL deionized water, and magnetically stirred at 25°C to dissolve it completely, forming a uniform and transparent solution;

[0057] 2) Add 6.6ml of ammonia water dropwise to the solution obtained in step 1), stir while adding, adjust the pH to 9.5,

[0058] 3) Transfer the solution obtained in step 2) into a 100ml reaction kettle, and put a 3*3cm 2 carbon cloth,

[0059] 4) Put the reaction kettle into an oven at 90°C, keep it warm for 24 hours, take out the carbon cloth, rinse it repeatedly with deionized water and alcohol, and then put it in an oven at 70°C for one night.

[0060] 5) Put the carbon cloth obtained in step 4) into a glass dish, and spread a certain amount of dimethylimidazole on the bottom of the glass dish, cover and seal the reaction dish, and m...

Embodiment 3

[0064] 1) 7.5mmol hexamethylenetetramine, 7.5mmol Zn(NO 3 ) 3 ·6H 2 O was added to 50.0mL deionized water, and magnetically stirred at 25°C to dissolve it completely, forming a uniform and transparent solution;

[0065] 2) Add 4.5ml of ammonia water dropwise to the solution obtained in step 1), stir while adding, adjust the pH to 8,

[0066] 3) Transfer the solution obtained in step 2) into a 100ml reaction kettle, and put a 3*3cm 2 carbon cloth,

[0067] 4) Put the reaction kettle into an oven at 90°C, keep it warm for 15 hours, take out the carbon cloth, rinse it repeatedly with deionized water and alcohol, and then put it in an oven at 70°C for one night.

[0068] 5) Put the carbon cloth obtained in step 4) into a glass dish, spread a certain amount of dimethylimidazole on the bottom of the glass dish, cover and seal the reaction dish, and move it into a vacuum oven at 90°C for heating for 3 hours.

[0069] 6) the carbon of step 5) is placed in the tube furnace, under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com