Flexible perovskite solar cell production technology

A technology for solar cells and preparation processes, applied in the field of solar cells, can solve problems such as inapplicability of flexible perovskite cells, unfavorable large-area preparation of batteries, and difficult problems of battery industrialization, and achieve the advantages of large-area industrial preparation, light weight, The effect of taking up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

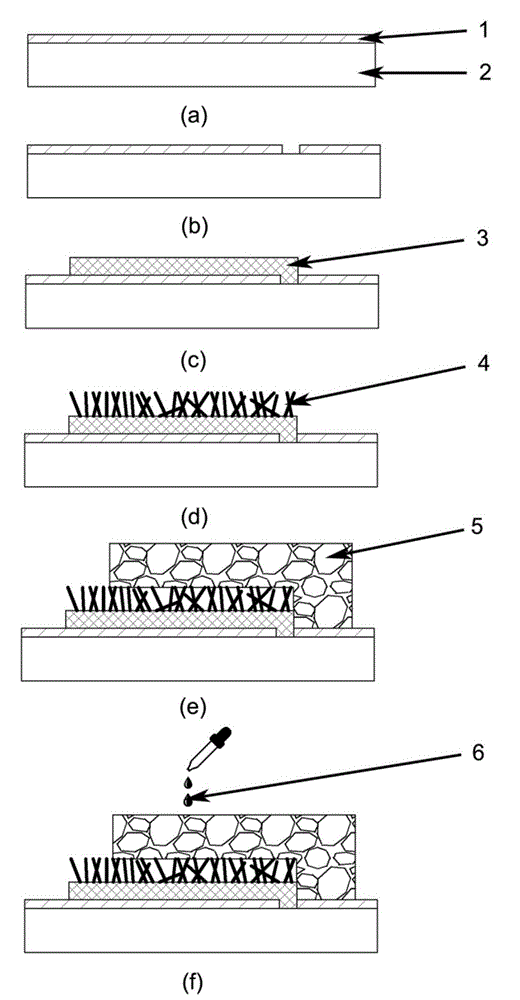

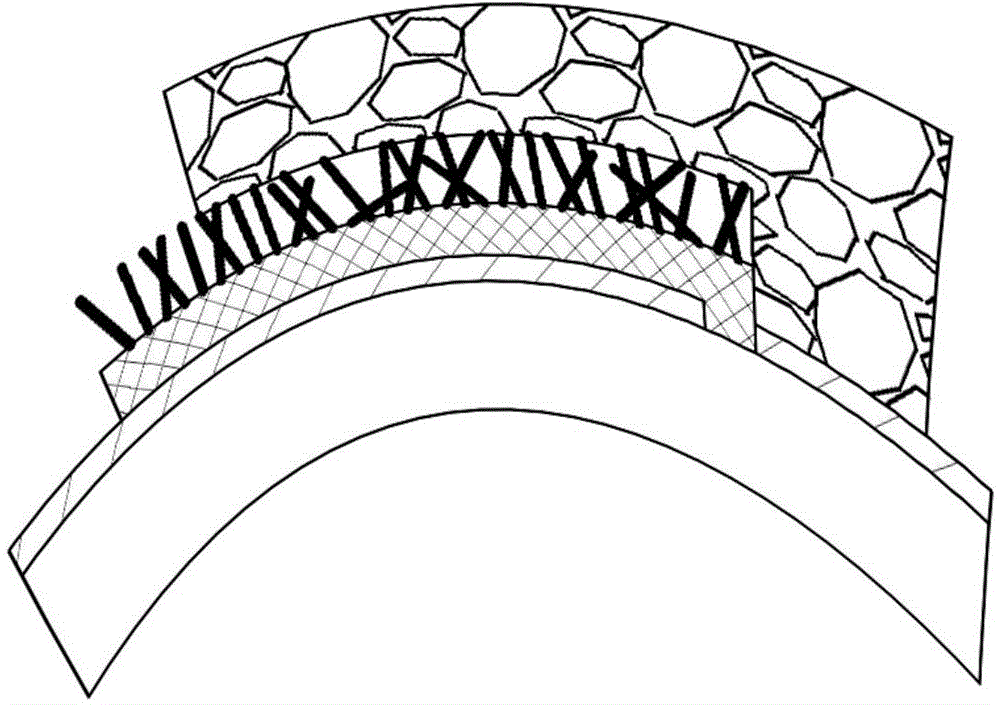

[0031] 1) Etching: use PET-ITO as the flexible conductive substrate (including ITO conductive layer 1 and PET substrate layer 2), etch a separation groove on the ITO conductive layer 1, and then clean the flexible conductive substrate; using etching solution The etching solution for the ITO conductive layer 1 is prepared from zinc powder and 2mol / L dilute hydrochloric acid, and the mass ratio of the two is 1:20. The flexible conductive substrate used is a PET film with a thickness of 0.15 mm, and ITO is sputtered by magnetron sputtering technology. ℃.

[0032] 2) Preparation of the photoanode: deposit a layer of ZnO dense layer 3 on the cleaned conductive substrate by cathodic electrochemical deposition, then use magnetron sputtering to coat a layer of ZnO seed layer on the ZnO dense layer 3, and then The ZnO nanowire 4 with a length of 0.5 μm is grown on the ZnO dense layer 3 by the hydrothermal method to obtain the photoanode of the solar cell; the reaction solution used by...

Embodiment 2

[0036] 1) Etching: use PET-ITO as the flexible conductive substrate (including ITO conductive layer 1 and PET substrate layer 2), etch a separation groove on the ITO conductive layer 1, and then clean the flexible conductive substrate; using etching solution The etching solution for the ITO conductive layer 1 is prepared from zinc powder and 1.5 mol / L dilute hydrochloric acid, and the mass ratio of the two is 1:15. The flexible conductive substrate used is a PET film with a thickness of 0.18 mm, and ITO is sputtered by magnetron sputtering technology. The substrate square resistance of the flexible conductive substrate is 6Ω / □, the light transmittance is greater than 80%, and the withstand temperature is 160 ℃.

[0037] 2) Preparation of the photoanode: deposit a layer of ZnO dense layer 3 on the cleaned conductive substrate by cathodic electrochemical deposition, then use magnetron sputtering to coat a layer of ZnO seed layer on the ZnO dense layer 3, and then The ZnO nanowi...

Embodiment 3

[0041] 1) Etching: use PET-ITO as the flexible conductive substrate (including ITO conductive layer 1 and PET substrate layer 2), etch a separation groove on the ITO conductive layer 1, and then clean the flexible conductive substrate; using etching solution The etching solution for the ITO conductive layer 1 is prepared from zinc powder and 3mol / L dilute hydrochloric acid, and the mass ratio of the two is 1:10. The flexible conductive substrate used is a PET film with a thickness of 0.20 mm, and ITO is sputtered by magnetron sputtering technology. ℃.

[0042] 2) Preparation of the photoanode: deposit a layer of ZnO dense layer 3 on the cleaned conductive substrate by cathodic electrochemical deposition, then use magnetron sputtering to coat a layer of ZnO seed layer on the ZnO dense layer 3, and then ZnO nanowires 4 with a length of 2 μm are grown on the ZnO dense layer 3 by the hydrothermal method to obtain the photoanode of the solar cell; the reaction solution used by the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Temperature tolerance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com