Preparation method of modified carbon fiber-reinforced composite ceramic

A fiber-reinforced composite and modified carbon technology, applied in the field of aluminum electrolysis, can solve the problems of the inability to effectively improve the mechanical properties of the ceramic matrix, the poor wettability of the metal coating and the ceramic matrix, and the reduction of the original strength of the carbon fiber, etc. To achieve the effect of promoting sintering, strengthening the interface strength, and increasing the interface bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1, its concrete steps are:

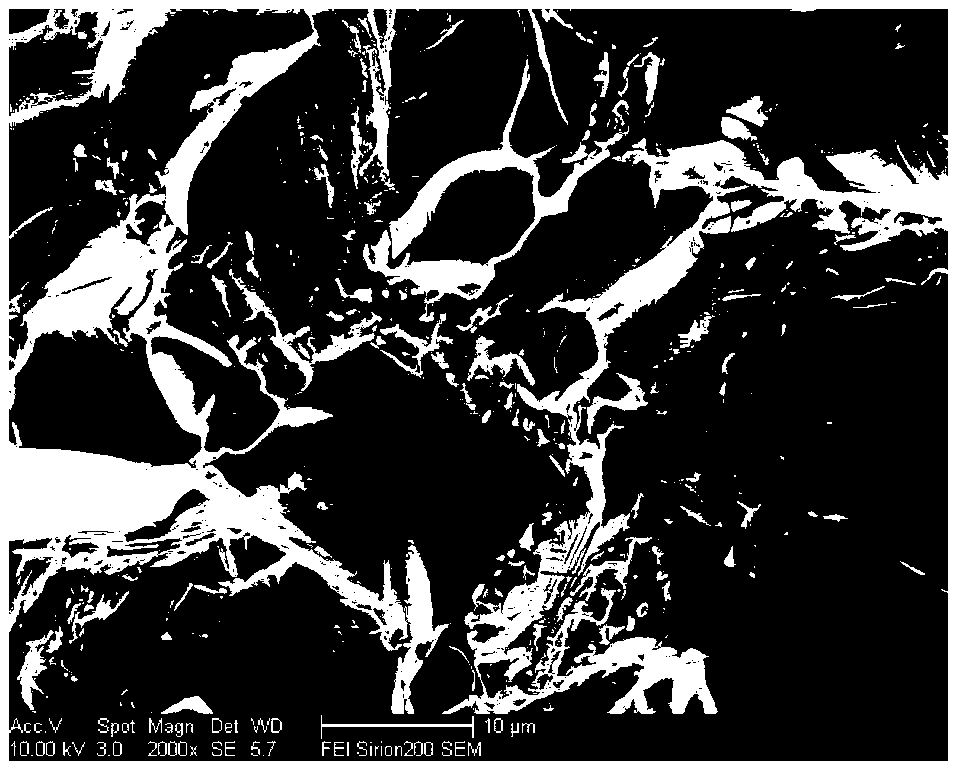

[0017] (1) Clean the carbon fiber and soak it in concentrated nitric acid for 5 minutes, then wash it with deionized water to remove excess nitric acid attached to the surface;

[0018] (2) Separately heat zinc acetate ethanol solution and NaOH ethanol solution with a molar concentration of 0.01M to 65°C, mix them in equimolar ratio, stir for 1 hour, and make a stable ZnO sol;

[0019] (3) Immerse the carbon fiber in ZnO sol for 10 minutes, take it out and dry it at 120°C for 10 minutes, then repeat the dipping and pulling twice, and pre-set ZnO seeds on the carbon fiber;

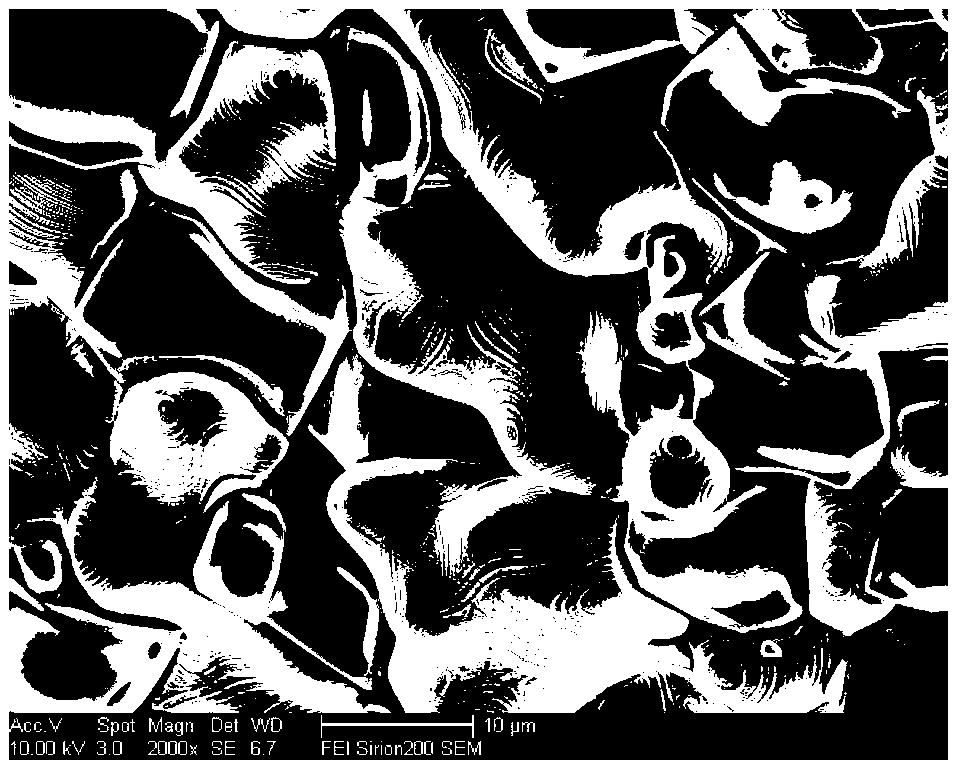

[0020] (4) Pour the zinc nitrate solution and the hexamethylenetetramine solution with a molar concentration of 12mM into the beaker, mix them evenly to make a growth solution, put the carbon fiber pre-prepared with ZnO seeds into the growth solution and Put it in a water bath, keep it warm at 90°C for 4 hours, take it out and wash it repeatedly, and then dry ...

Embodiment 2

[0025] (1) After cleaning the carbon fiber, soak it in concentrated nitric acid for 8 minutes, and then wash it with deionized water to remove excess nitric acid attached to the surface;

[0026] (2) Separately heat zinc acetate ethanol solution and NaOH ethanol solution with a molar concentration of 0.2M to 65°C, mix them in equimolar ratio, stir for 2 hours, and make a stable ZnO sol;

[0027] (3) Immerse the carbon fiber in ZnO sol for 5 minutes, take it out and dry it at 100°C for 20 minutes, then repeat the dipping and pulling twice, and pre-set ZnO seeds on the carbon fiber;

[0028](4) Pour equimolar zinc sulfate solution and hexamethylenetetramine solution with a molar concentration of 1mM into a beaker, mix well to make a growth solution, put the carbon fiber pre-prepared with ZnO seeds into the growth solution and Put it in a water bath, keep it warm at 80°C for 2 hours, take it out and wash it repeatedly, and then dry it at 70°C to obtain a ZnO nanowire array film o...

Embodiment 3

[0032] (1) Clean the carbon fiber and soak it in concentrated nitric acid for 6 minutes, then wash it with deionized water to remove excess nitric acid attached to the surface;

[0033] (2) Separately heat zinc acetate ethanol solution and NaOH ethanol solution with a molar concentration of 0.1M to 65°C, mix them in equimolar ratio, stir for 1.5h, and make a stable ZnO sol;

[0034] (3) Immerse the carbon fiber in ZnO sol for 7 minutes, take it out and dry it at 110°C for 15 minutes, then dip and pull it once, and pre-set ZnO seeds on the carbon fiber;

[0035] (4) Pour equimolar zinc chloride solution and hexamethylenetetramine solution with a molar concentration of 25mM into a beaker, mix evenly to make a growth solution, put the carbon fiber pre-prepared with ZnO seeds into the growth solution and then Put them together in a water bath, keep them warm at 85°C for 8 hours, take them out and wash them repeatedly, and then dry them at 100°C to obtain a ZnO nanowire array film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com