Induction welding production line of power module

A technology for power module and induction welding, which is applied in the direction of high-frequency current welding equipment, welding equipment, welding equipment, etc., which can solve the problem of long feeding path, long feeding time, inability to meet the sequential feeding of copper shell and bottom cover plate, and Placement and other issues to achieve the effect of shortening the path length, avoiding confusion and congestion, and overcoming difficulties in control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

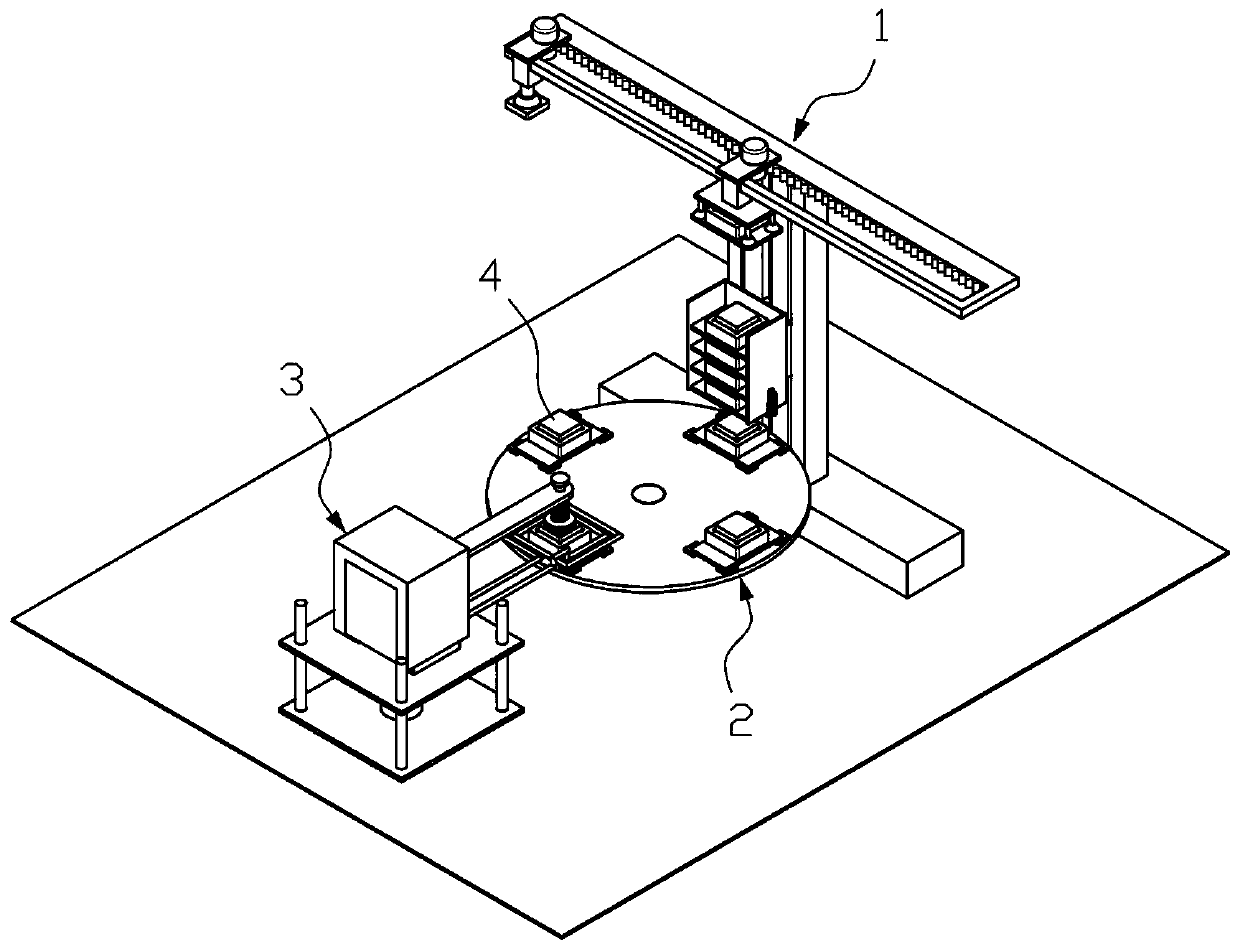

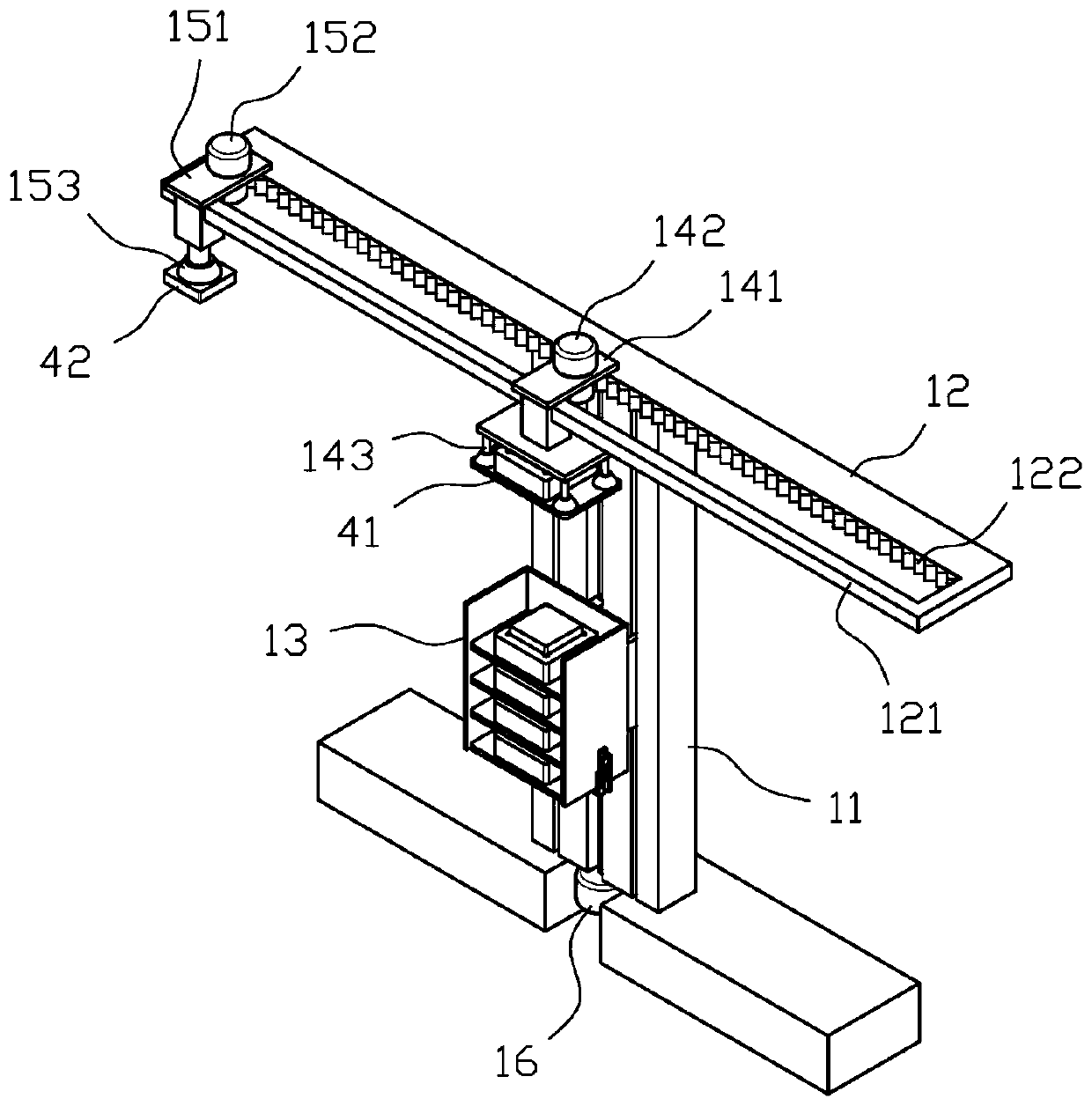

[0035] Such as figure 1 — Figure 11 As shown, the present invention provides an induction welding production line for power modules, including:

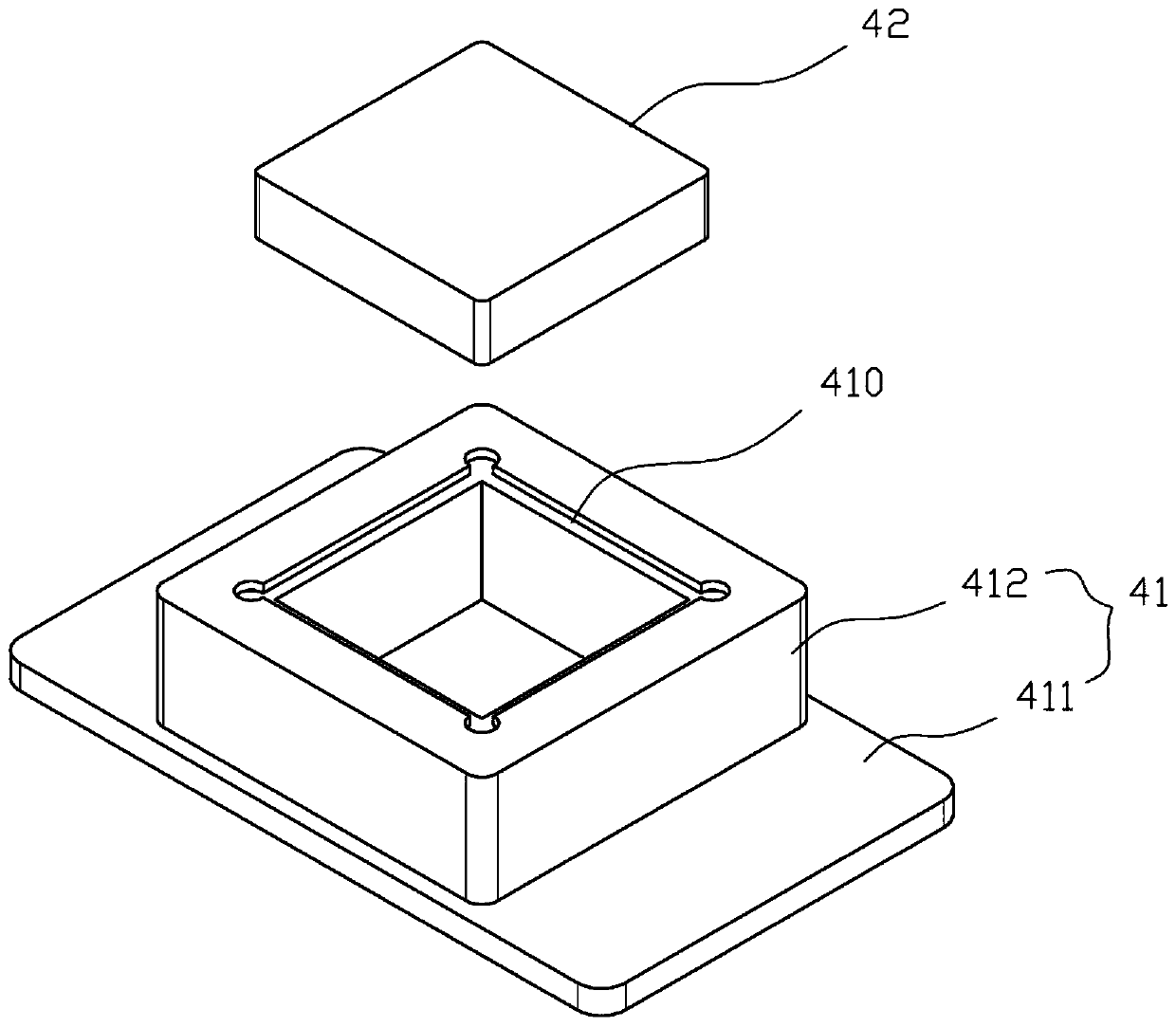

[0036] The batching unit 1 is capable of retrieving the shell 41 and the cover plate 42 respectively, and pairing them into a power module 4;

[0037] The jig unit 2 is used to carry and limit the power supply module 4 that falls from the batching unit 1; and

[0038] The welding unit 3 is capable of pressing the top of the power module 4 to be welded, and welding the shell 41 and the cover plate 42 into one;

[0039] Wherein, the jig unit 2 includes a rotatable material transfer plate 21 for guiding the power supply module 4 from the batching unit 1 to the welding unit 3 .

[0040] In the present invention, it uses the batching ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com