Antireflection type super-hydrophilic zinc oxide/titanium dioxide composite nanometer structure self-cleaning coating and preparation method thereof

A composite nanostructure, self-cleaning coating technology, applied in the field of chemical materials, can solve problems such as increasing the air-transparent substrate interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] ① Preparation of ZnO seed layer: Add equivalent ethanolamine to 0.2mol / L zinc acetate ethanol solution. The solution was spin-coated on a clean FTO conductive glass substrate at 3000 rpm. The substrate was then calcined at 400°C for 30 minutes.

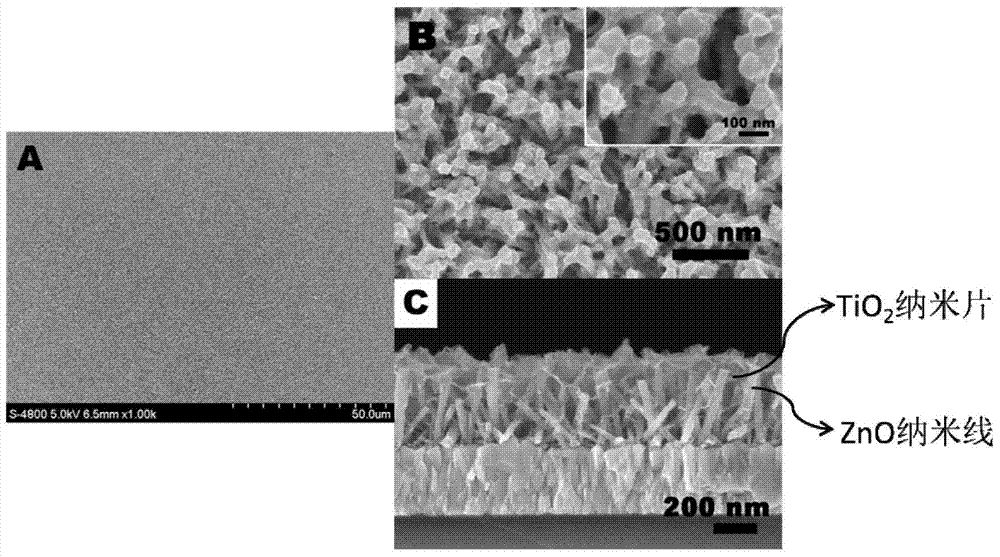

[0036] ②Growth of ZnO nanowire array: prepare 20mmol / L zinc nitrate aqueous solution, and add equimolar hexamethylenetetramine to the zinc nitrate solution. Submerge the substrate prepared in ① into the above solution and keep the substrate upright. The reaction system was placed in a constant temperature oven at 70° C. for 4 hours to obtain a ZnO nanowire array with a diameter of about 400 nanometers.

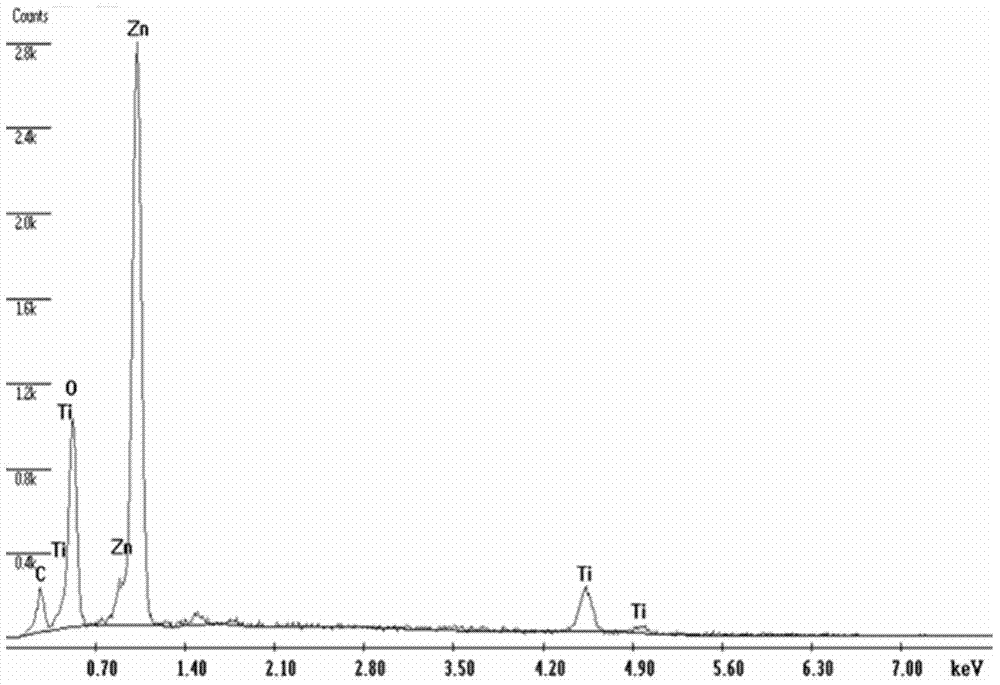

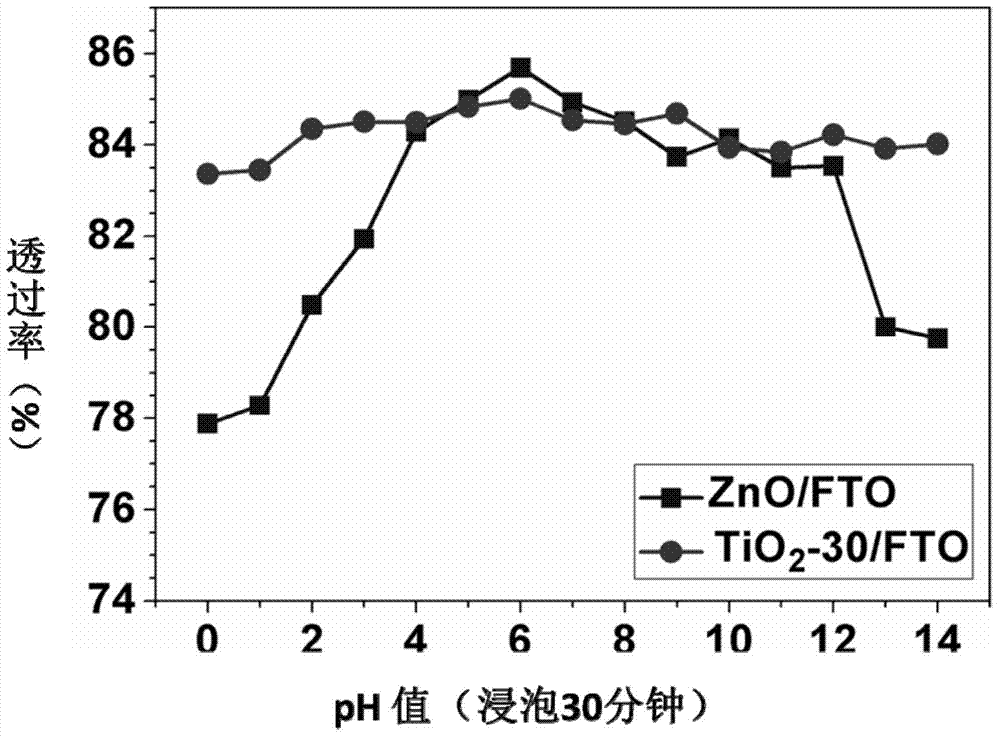

[0037] ③ZnO / TiO 2 Composite nanostructure film: The substrate prepared in ② with ZnO nanowire array grown upright in the hydrothermal reaction kettle, add 10mL isopropanol solution of titanate in the reaction kettle, the concentration of titanate in the solution to 5 mmol / L, add 10 microliters of diethylenetriamine. The ab...

Embodiment 2

[0040] ① Preparation of ZnO seed layer: Add equivalent amount of ethylamine to 0.1mol / L zinc acetate ethanol solution. The solution was spin-coated on a clean FTO conductive glass substrate at 2000 rpm. The substrate was then calcined at 400°C for 50 minutes.

[0041] ②Growth of ZnO nanowire array: prepare 30mmol / L zinc nitrate aqueous solution, and add equimolar hexamethylenetetramine to the zinc nitrate solution. Submerge the substrate prepared in ① into the above solution and keep the substrate upright. The reaction system was placed in a constant temperature oven at 70° C. for 6 hours to obtain a ZnO nanowire array with a diameter of about 450 nanometers.

[0042] ③ZnO / TiO 2 Composite nanostructure film: The substrate prepared in ② with ZnO nanowire arrays grown upright in a hydrothermal reaction kettle was added to the reaction kettle with 15mL of isopropanol solution of titanate, the concentration of titanate in the solution To 10mmol / L, add 10 microliters of triethy...

Embodiment 3

[0044] ① Preparation of ZnO seed layer: Add equivalent ethylenediamine to 0.3mol / L zinc acetate ethanol solution, spin-coat the solution on a clean substrate at 3000rpm, and then calcinate the substrate at 500°C for 60 minute;

[0045] ②Growth of ZnO nanowire array: prepare 50mmol / L zinc nitrate aqueous solution, and add equimolar hexamethylenetetramine to the zinc nitrate solution; immerse the substrate prepared in step ① in the above solution, keep the substrate The sheet was upright; the reaction system was placed in a constant temperature oven at 90°C for 2 hours to obtain a ZnO nanowire array with a thickness of 500 nm;

[0046] ③ZnO / TiO 2 Composite structure nano film: the substrate prepared in step ② with ZnO nanowire array grown upright in the hydrothermal reaction kettle, add 20mL isopropanol / water (1:1) solution of titanyl sulfate in the reaction kettle , the concentration of titanyl sulfate in the solution is 50mmol / L, and then add 40 microliters of tetraethylenep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com