Composite resistance NH3 gas-sensitive gas sensor and preparation method thereof

A gas sensor and composite resistance technology, applied in the direction of material resistance, etc., can solve the problems of high energy consumption and high working temperature, and achieve the effects of simple preparation method, lower working temperature, and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: A composite resistive NH 3 Gas sensitive gas sensor, it is prepared by following scheme:

[0041] (1) Material preparation

[0042] (1) The specific method for preparing polyaniline nanotubes is:

[0043] Include the following steps in turn:

[0044] (a) purifying aniline through secondary distillation in the presence of zinc powder;

[0045] (b) 2mol / l freshly distilled aniline is dissolved in 1mol / L hydrochloric acid;

[0046] (c) Slowly add 2 mol / l (NH4)2S2O8 solution dropwise therein under stirring state, the dropwise addition time is about 40min, and react for 6h after the dropwise addition;

[0047] (d) Suction filtration after the reaction stopped, the filter cake was washed with hydrochloric acid, deionized water and absolute ethanol respectively, and then vacuum-dried at 60° C. / 0.01 MPa for 24 hours to obtain HCl-doped polyaniline nanotubes.

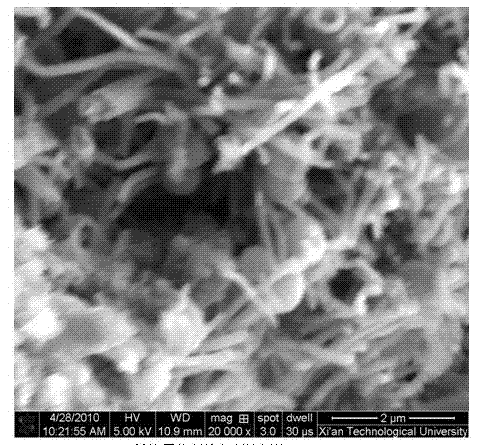

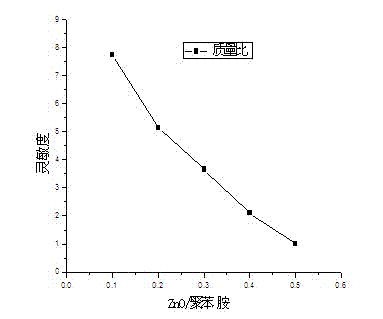

[0048] see figure 1 , at 25°C, when the ratio of aniline, ammonium persulfate, and hydrochloric aci...

Embodiment 3

[0085] (1) Material preparation

[0086] (1) The specific method for preparing polyaniline nanotubes is:

[0087] Include the following steps in turn:

[0088] (a) purifying aniline through secondary distillation in the presence of zinc powder;

[0089] (b) 2mol / l freshly distilled aniline is dissolved in 1mol / L hydrochloric acid;

[0090] (c) Slowly add 3mol / l (NH4)2S2O8 solution dropwise therein under stirring state, the dropwise addition time is about 30min, and react for 6h after the dropwise addition;

[0091] (d) Suction filtration after the reaction stopped, the filter cake was washed with hydrochloric acid, deionized water and absolute ethanol respectively, and then vacuum-dried at 60° C. / 0.01 MPa for 24 hours to obtain HCl-doped polyaniline nanotubes.

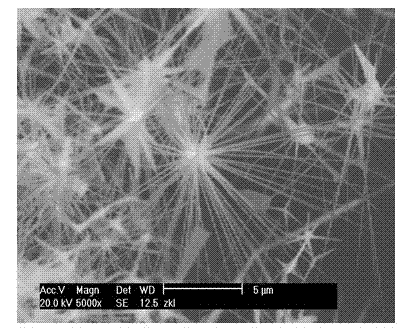

[0092] (2) Preparation of ZnO nanowires without any catalyst

[0093] Using Zn powder as raw material, ZnO nanowires were prepared by using a horizontal high-temperature tube furnace through physical thermal evapor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com