Modified zeolite ammonia nitrogen adsorbent and application and regeneration method thereof

A technology of modified zeolite and adsorbent, which is applied in chemical instruments and methods, separation methods, filter regeneration, etc. It can solve the problems of ammonia nitrogen removal agent that has not yet been seen, high environmental conditions, and slow growth of nitrifying bacteria. To achieve the effect of abundant reserves, good adsorption effect and stable water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

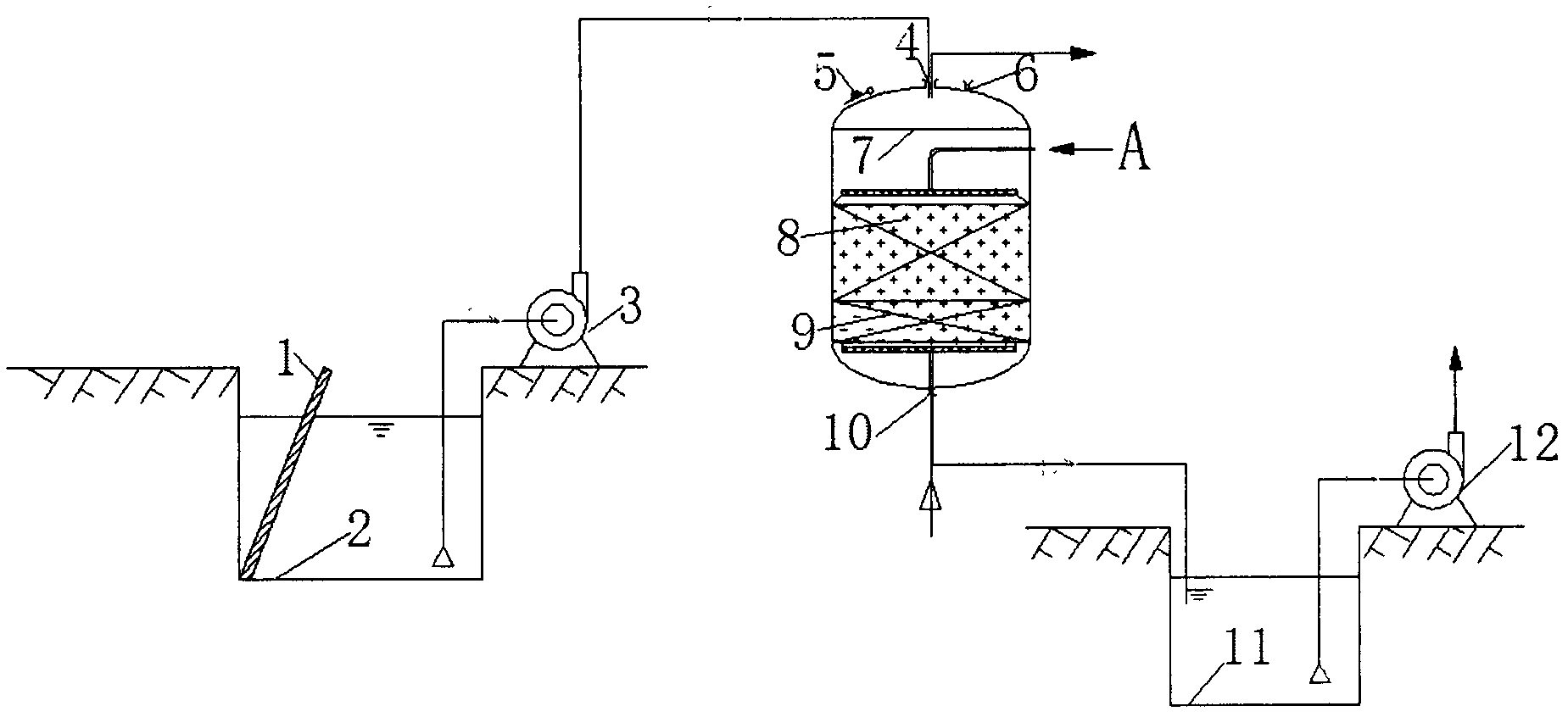

[0027] The preparation method of modified zeolite ammonia nitrogen adsorbent of the present invention is to carry out according to the following operation steps:

[0028] (1) First, the natural zeolite is crushed and ground, then passed through a 20-40 mesh sieve, soaked in sulfuric acid with a volume concentration of 2%-10% for 24 hours, washed until the pH is 6.5-7.5, and placed at 120°C-150 Steam at ℃ for 16-24h, then dry at 105℃ and cool to room temperature for later use;

[0029] (2) by CuSO 4 ·5H 2 The weight ratio of O and the above-mentioned treated zeolite is 1:3 and takes CuSO 4 ·5H 2 Dissolve O in ultrapure water, then mix with zeolite, stir evenly, react at 650°C for 24 hours, cool to room temperature and wash off unloaded surface particles, until the solution is washed out to a pH of 6.5-7.5, then Dry at a temperature of 100°C-150°C to obtain the finished modified zeolite ammonia nitrogen adsorbent.

[0030] Use the product modified zeolite ammonia nitrogen a...

Embodiment 1

[0035] (1) First crush and grind the natural zeolite, then pass through a 30-mesh sieve, soak in sulfuric acid with a volume concentration of 5% for 24 hours, wash until the pH is 7.0, steam at 120°C for 24 hours, and then dry at 105°C After cooling to 25°C, set aside;

[0036] (2) Weigh 100g CuSO 4 ·5H 2 Dissolve O in ultrapure water, mix with 300g of spare zeolite after the above treatment, stir evenly, react at 650°C for 24h, cool to 25°C and wash off unloaded surface particles until the pH of the eluting solution is 7.0 , and then dried at a temperature of 150°C to obtain a modified zeolite ammonia nitrogen adsorbent;

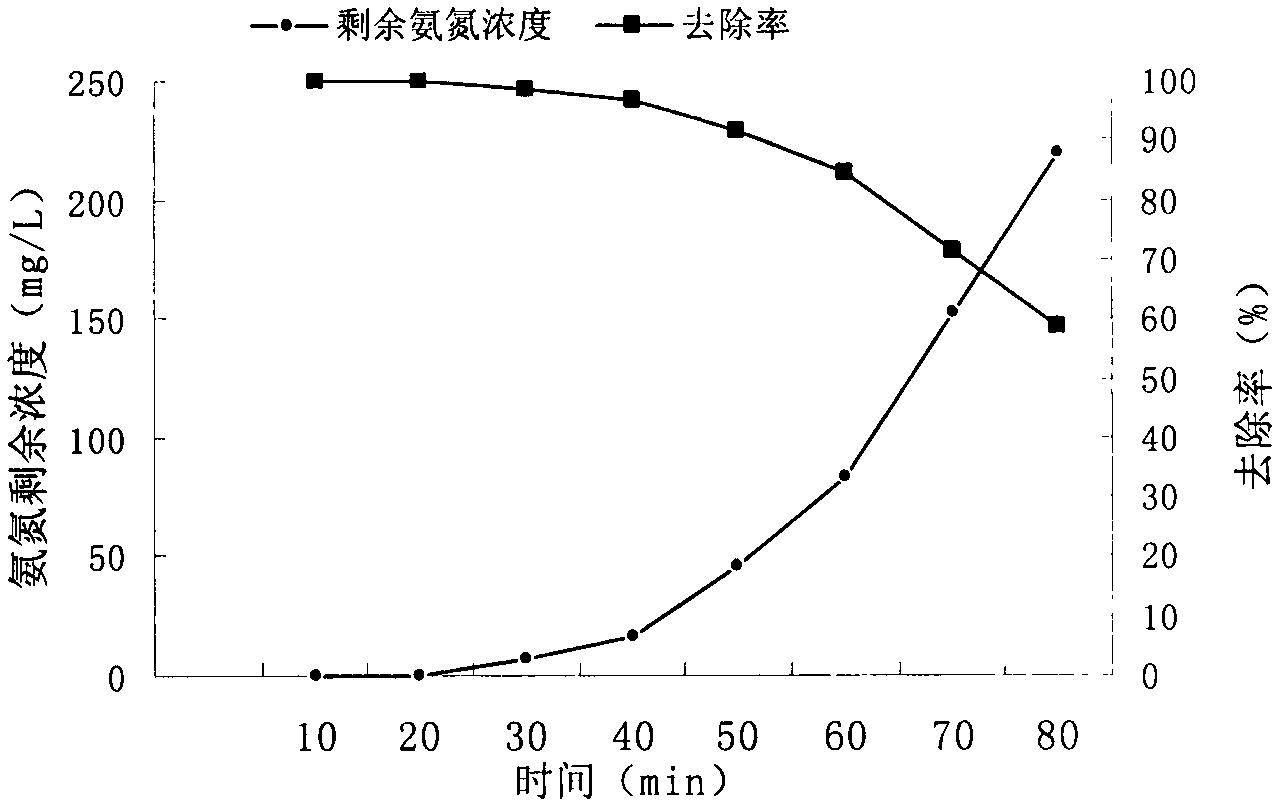

[0037] (3) Choose plexiglass as the adsorption column, add 3m modified zeolite ammonia nitrogen adsorbent in the column, enter the waste water from the smelter into the sump through the grid, adjust the pH to 9 with sodium hydroxide, and pump it into the adsorption In the column, after treatment, it enters the clean water pool for reuse. Through monitor...

Embodiment 2

[0040] (1) First crush and grind the natural zeolite, then pass through a 20-mesh sieve, soak in sulfuric acid with a volume concentration of 10% for 24 hours, wash until the pH is 6.5, steam at 150°C for 16 hours, and then dry at 105°C After cooling to 25°C, set aside;

[0041] (2) Weigh 100g CuSO 4 ·5H 2 O is dissolved in ultrapure water, mixed with 300g of spare zeolite that has been treated and dried before, stirred evenly, reacted at 650°C for 24h, cooled to room temperature at 25°C, washed off the unloaded surface particles, and the pH of the washed solution When it is 7.0, it is then dried at 120°C to obtain a modified zeolite ammonia nitrogen adsorbent.

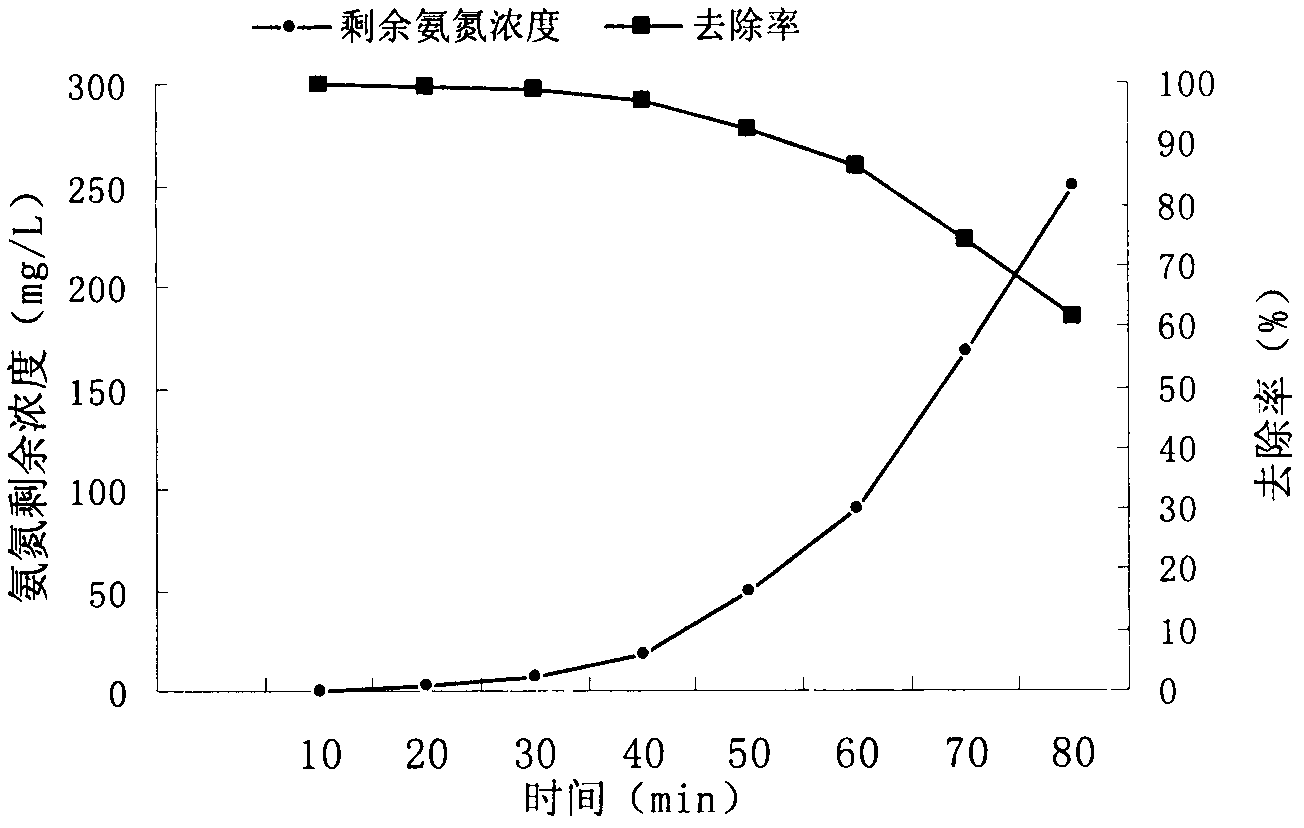

[0042] (3) Choose plexiglass as the adsorption column, add 3m modified zeolite ammonia nitrogen adsorbent in the column, enter the waste water retrieved from the garbage dump into the sump through the grid, adjust the pH to 9 with sodium hydroxide, and pump it into the adsorption column In the column, after treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com