Method and device for purifying electrolytic aluminum smoke

A purification device and a technology for electrolytic aluminum, which are applied in chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve the problems of reducing the efficiency of fluoride adsorption and purification, unsatisfactory flue gas purification effect, and increased workload of filter bags. , to achieve the effect of high working efficiency, improving recycling rate and improving adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing by embodiment:

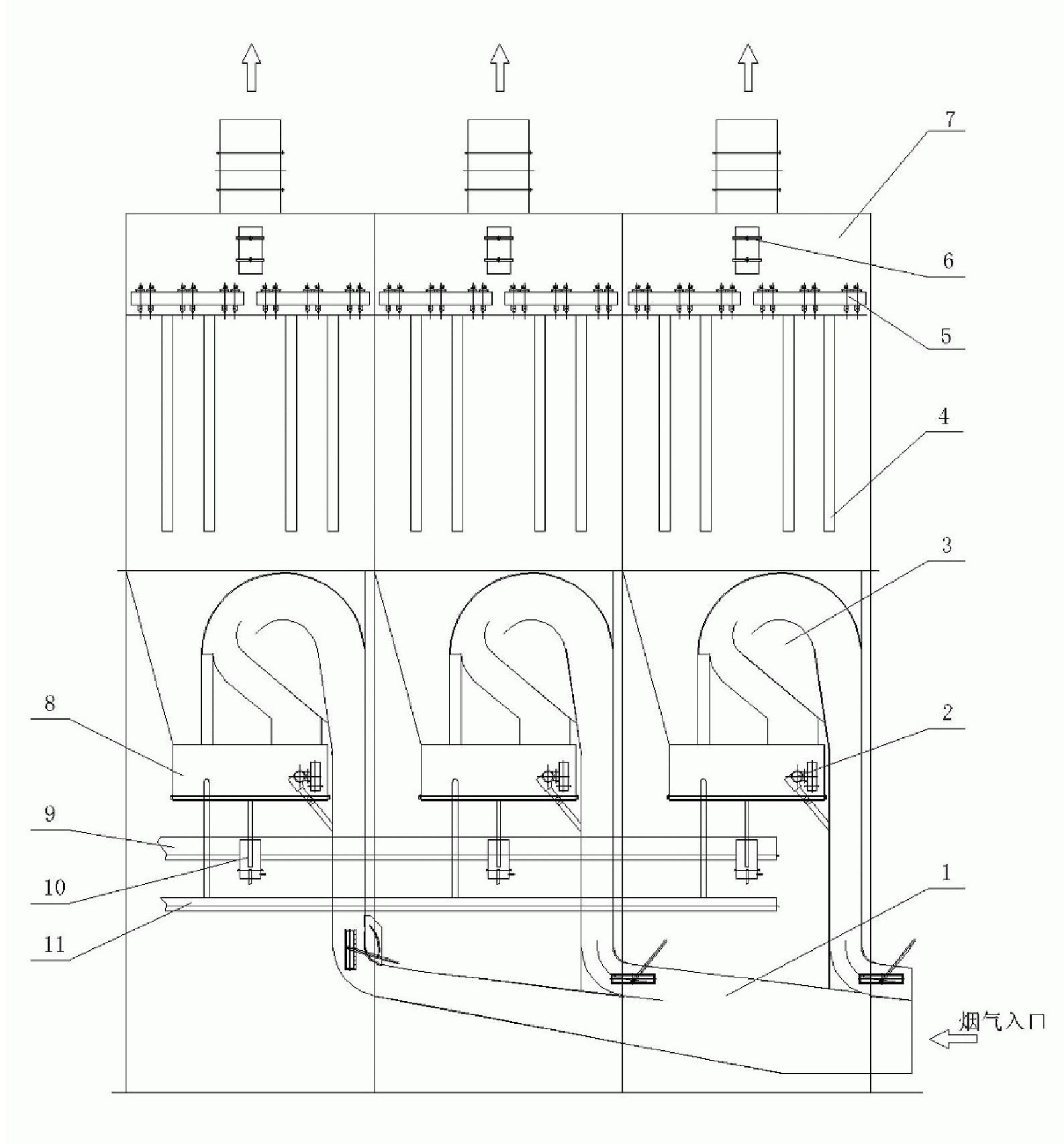

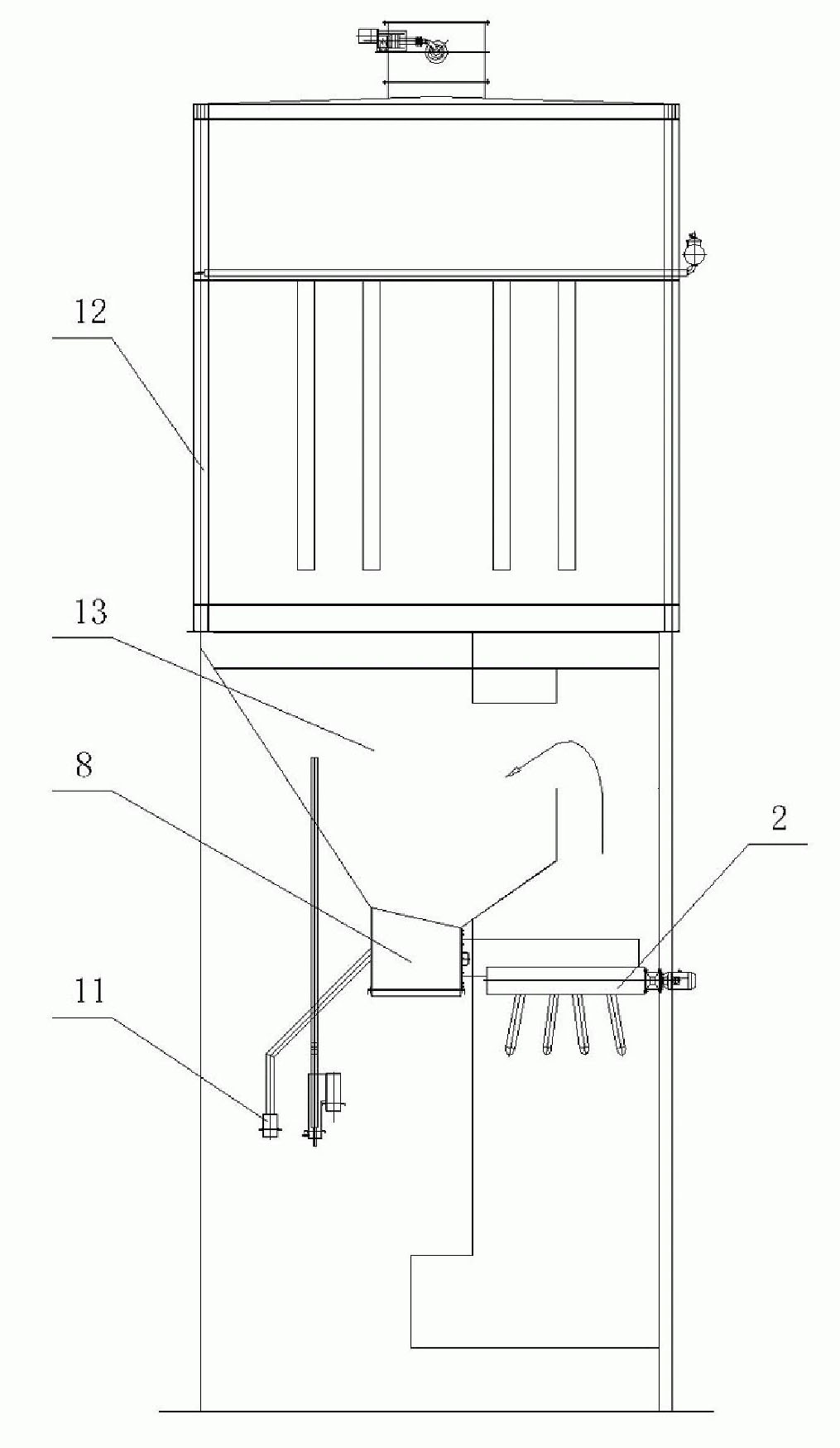

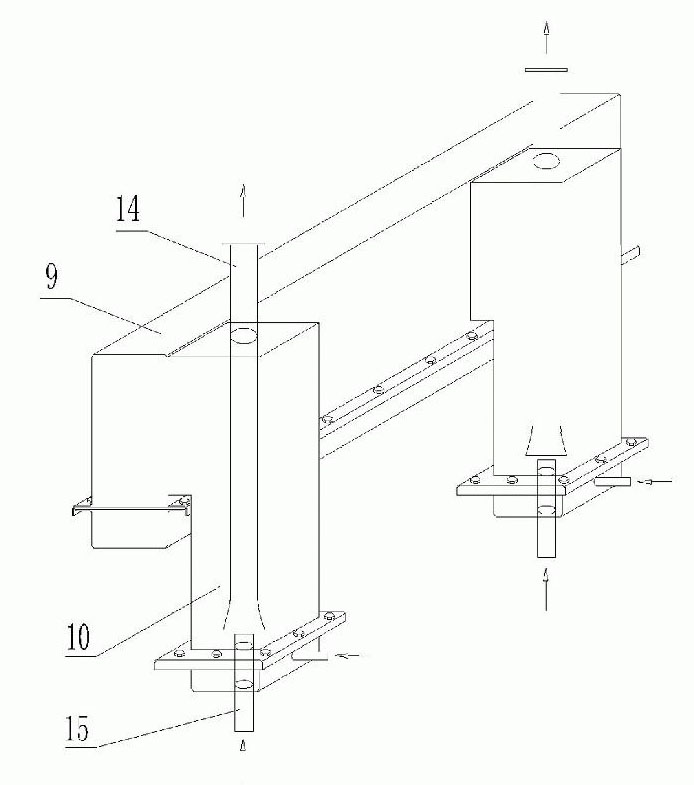

[0015] Embodiments of the present invention: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a method and device for purifying electrolytic aluminum flue gas use the suction of the induced draft fan to suck the flue gas in the electrolytic cell into the inlet pipe 1, and distribute and guide the flow through the deflector, so that the flue gas entering each filter unit The air volume is equal. The flue gas after diversion and distribution enters the smoke inlet 1 of the lower box 13 in the lower R-shaped flue 3, and the fluorine-containing alumina in the ash hopper fluidized bed 8 enters the frequency conversion feeder 2 through the chute 16 , the frequency conversion feeder 2 is driven by a frequency conversion machine 17 to rotate, and alumina is sprayed into the flue gas passing through the R-type flue 3 through 4-6 injection hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com