Method of treating heavy metal industrial effluent with turf as adsorbent

A technology for industrial wastewater and adsorbents, applied in the direction of adsorption water/sewage treatment, water/sludge/sewage treatment, energy wastewater treatment, etc., can solve the need for sludge dehydration equipment, low industrial added value, large footprint, etc. problems, to achieve the effect of low requirements on equipment and adsorption conditions, low treatment cost, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1 The continuous adsorption and precipitation process is used to treat heavy metal industrial wastewater containing Cd. The initial concentration of Cd = 1.12mg L -1

[0044] The specific operation is as follows:

[0045] (1) For heavy metal wastewater from the factory, adjust the pH to 6 with soda lime. If there are many suspended particles and floating objects in the water, it needs to be settled or scum removed.

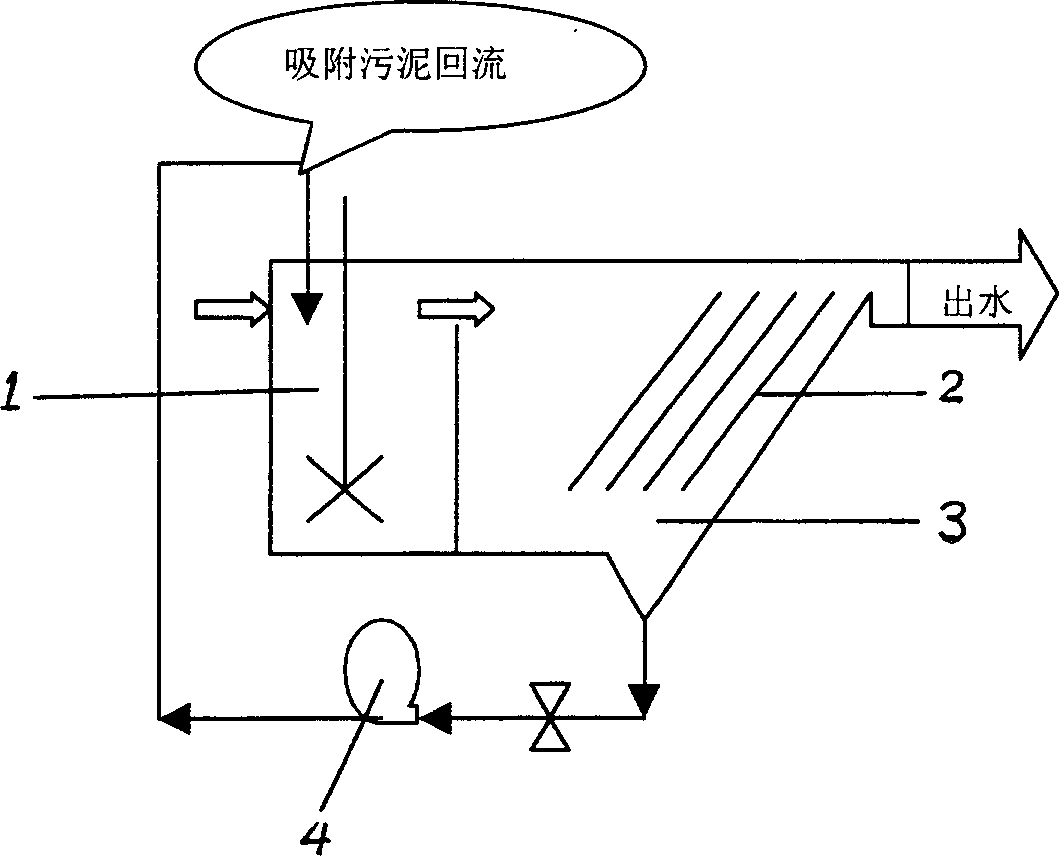

[0046] (2) if figure 1 As shown, add 2.0 kg of adsorbent / 1 ton of waste water to the reaction tank 1, and inject heavy metal waste water into the reaction tank under the condition that the stirring speed is 30 rpm, and the waste water flow rate (Q) is 5m 3 / h, the reaction pool volume (V) is 10m 3 , The average adsorption reaction time is 2.0h, the average adsorption reaction time (t) is determined by the flow rate (Q) and the volume of the adsorption reaction tank (V), t=V / Q, adjust the water flow rate and control the adsorption reaction time th...

Embodiment 2

[0049] Example 2 Pb-containing heavy metal wastewater, Pb initial concentration = 82.8mg L -1 , the influent pH=7.0, the dosage of adsorbent is 0.5kg adsorbent / ton of waste water.

[0050] The difference from Example 1 is that the adsorption treatment process is carried out in two reaction pools of different sizes by means of multi-stage variable speed stirring, and excessive adsorbent is added. The volume of the first reaction pool is 5m 3 , Stirring speed range 90 rpm, fast stirring; the volume of the second reaction tank is 20m 3 , the stirring speed is 10 rpm; the solid-liquid separation between the adsorbent and water is realized in the sedimentation tank. The sedimentation tank adopts inclined plate sedimentation, and the sludge settles at the bottom of the sedimentation tank, and is returned to the adsorption reaction tank by the sludge pump for recycling. adsorbent until the adsorption capacity of the adsorbent is reached.

[0051] Treatment effect: Pb effluent conce...

Embodiment 3

[0052] Example 3 The batch-type adsorption-sedimentation process was used to treat Pb-containing heavy metal wastewater, and the initial concentration of Pb was 2.07mg L -1 , influent pH=5.5, adsorbent dosage 1.0kg adsorbent / 1 ton of waste water.

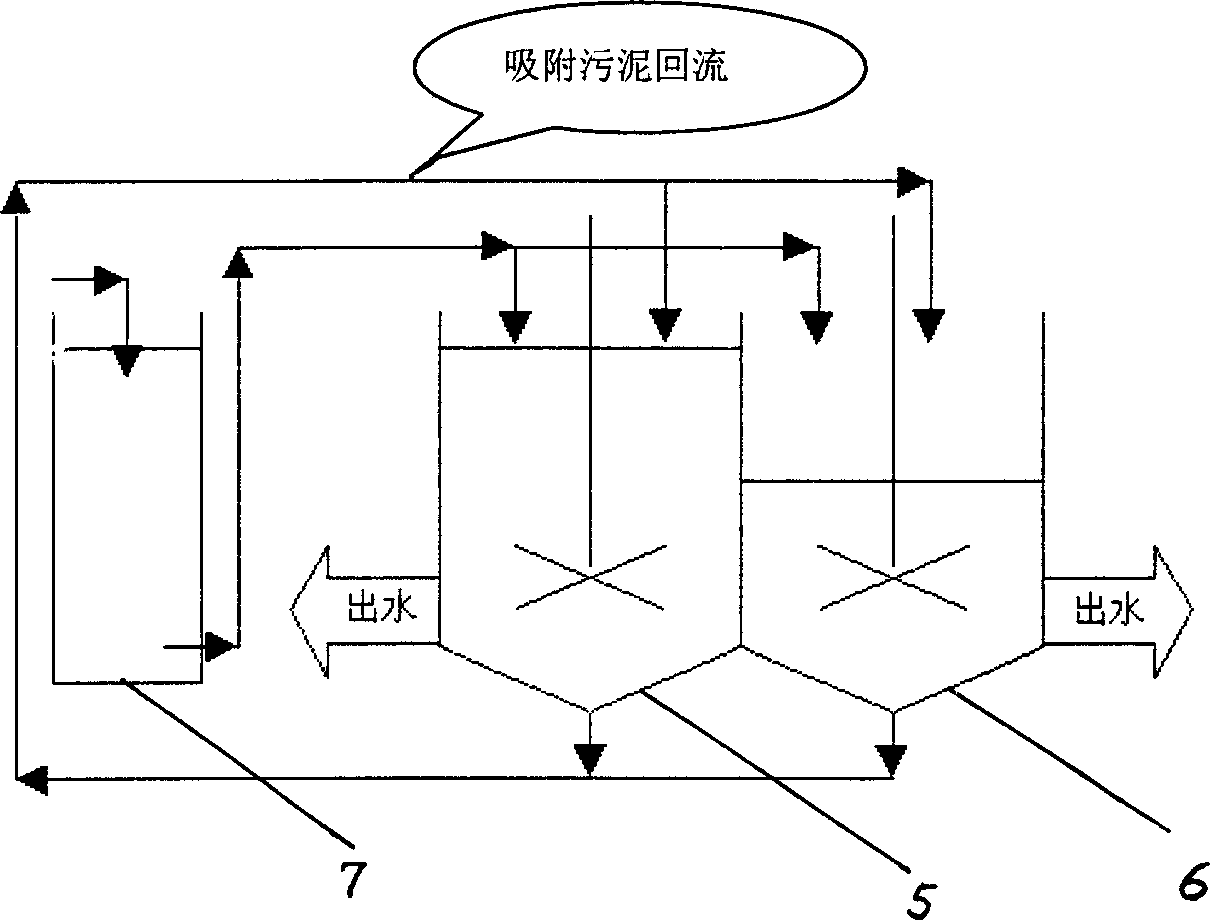

[0053] The adsorption process adopts the method of sedimentation after variable speed stirring, such as figure 2 As shown, the batch continuous adsorption reaction pools 5 and 6 have the same size, and the heavy metal wastewater to be treated is pumped into the first batch of continuous reaction pools 5 after pretreatment in the pretreatment pool 7, and the variation range and time of the stirring speed are as follows: 140 rpm, stirring rapidly for 2 minutes; stirring speed 40 rpm, stirring for 5 minutes; stirring speed 10 rpm, stirring for 30 minutes; finally, standing for precipitation for 2 hours. During the static sedimentation process of the first batch of continuous reaction tanks 5, the waste water is injected into the seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com