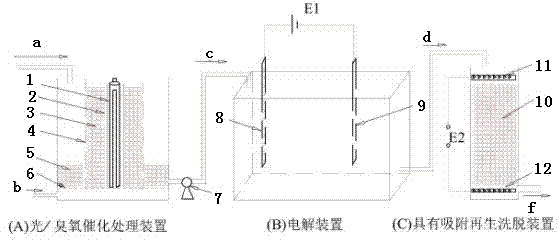

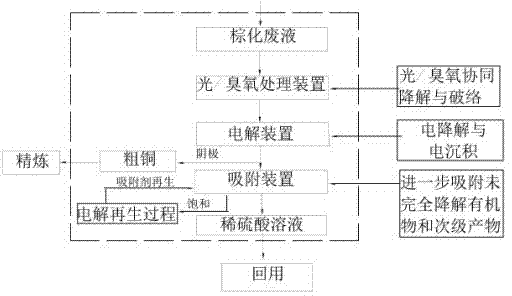

Light/ozone-electricity-adsorption reaction device and method for extracting copper by degrading browning waste liquor

An adsorption reaction and electrolysis device technology, applied in the field of light/ozone-electricity-adsorption multi-step synergistic reaction devices, can solve problems such as difficulty in breaking coordination bonds, and achieve the effects of simple manufacture, cost reduction, and low degradation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0037] Add 5g of titanium dioxide-supported catalyst, add 20g of manganese dioxide-supported catalyst, add 300ml of the original browning waste liquid (total Cu2+ concentration, 48.5g / L, COD value is about 50000) from (a) tube, and pass it into (b) OZ type ozone generator blows 3mg / L ozone, and treats it under an 8w ultraviolet lamp for 4h; then all of it is added to the electrolysis chamber, and at a constant current of 0.8A, adjust the cathode liquid junction area so that the current density is 4A / dm2, adjust The distance between the two poles is 3-8cm, so that the voltage is in the range of 3-5V, and the electrolysis is performed for 10 hours. After electrolysis, the solution is passed into the adsorption chamber for 2 hours. The COD value drops to 1208, the copper recovery rate reaches 57.3%, and the copper removal rate in the solution reaches 72.5% %, the current efficiency of electrolytic copper deposition is 53.7%. The electrolysis energy consumption per unit volume of ...

Embodiment approach 2

[0040] Add 500ml of the original browning waste liquid (total Cu2+ concentration is 48.5g / L, COD value is about 50000) to the light / ozone chamber treatment room after scheme 1, and treat it under 8w ultraviolet lamp and ozone concentration of 4mg / L 4h, under the constant current of 1A, adjust the cathode liquid junction area, make the current density 5A / dm2, and adjust the distance between the two electrodes to 3-8cm, make the voltage in the range window of 3-5V, carry out electrolysis for 10h, after electrolysis, the solution will be introduced into the adsorption After 2 hours of treatment in the chamber, the COD value dropped to 1349, the copper recovery rate reached 49.6%, the copper removal rate in the solution reached 65.3%, and the current efficiency of electrolytic copper deposition was 52.7%. The electrolysis energy consumption per unit volume of browning solution is 0.059KW·h / L, and the total energy consumed for degrading unit volume of browning waste solution is 0.63...

Embodiment approach 3

[0042] Add 500ml of the original browning waste liquid (total Cu2+ concentration is 40g / L, COD value is about 55000) to the light / ozone chamber treatment room after scheme 2, and treat it under 8w ultraviolet lamp and ozone concentration of 5mg / L for 4h , under a constant current of 1A, adjust the cathode liquid junction area to make the current density 3A / dm2, and adjust the distance between the two electrodes to 3-8cm, so that the voltage is in the range of 3-5V, perform electrolysis for 10h, and the solution after electrolysis is passed into the adsorption chamber After 2 hours of treatment, the COD value dropped to 2000, the copper recovery rate reached 52.3%, the copper removal rate in the solution reached 52.3%, and the electrolytic copper deposition current efficiency was 53.9%. The electrolysis energy consumption per unit volume (1L) of browning solution is 0.055KW·h, and the total energy consumed for degrading a unit volume (1L) of browning waste solution is 0.633KW·h....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com