Method for preparing, using and regenerating Fe-Mn-Al composite oxide/zeolite antimony removal adsorbent

A composite technology of oxide and aluminum, applied in chemical instruments and methods, separation methods, filter regeneration and other directions, can solve the problems of difficult to popularize and apply on a large scale, a large amount of antimony-containing waste residue, complicated preparation process, etc., and the method is simple and easy to implement. , Excellent water purification efficiency, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

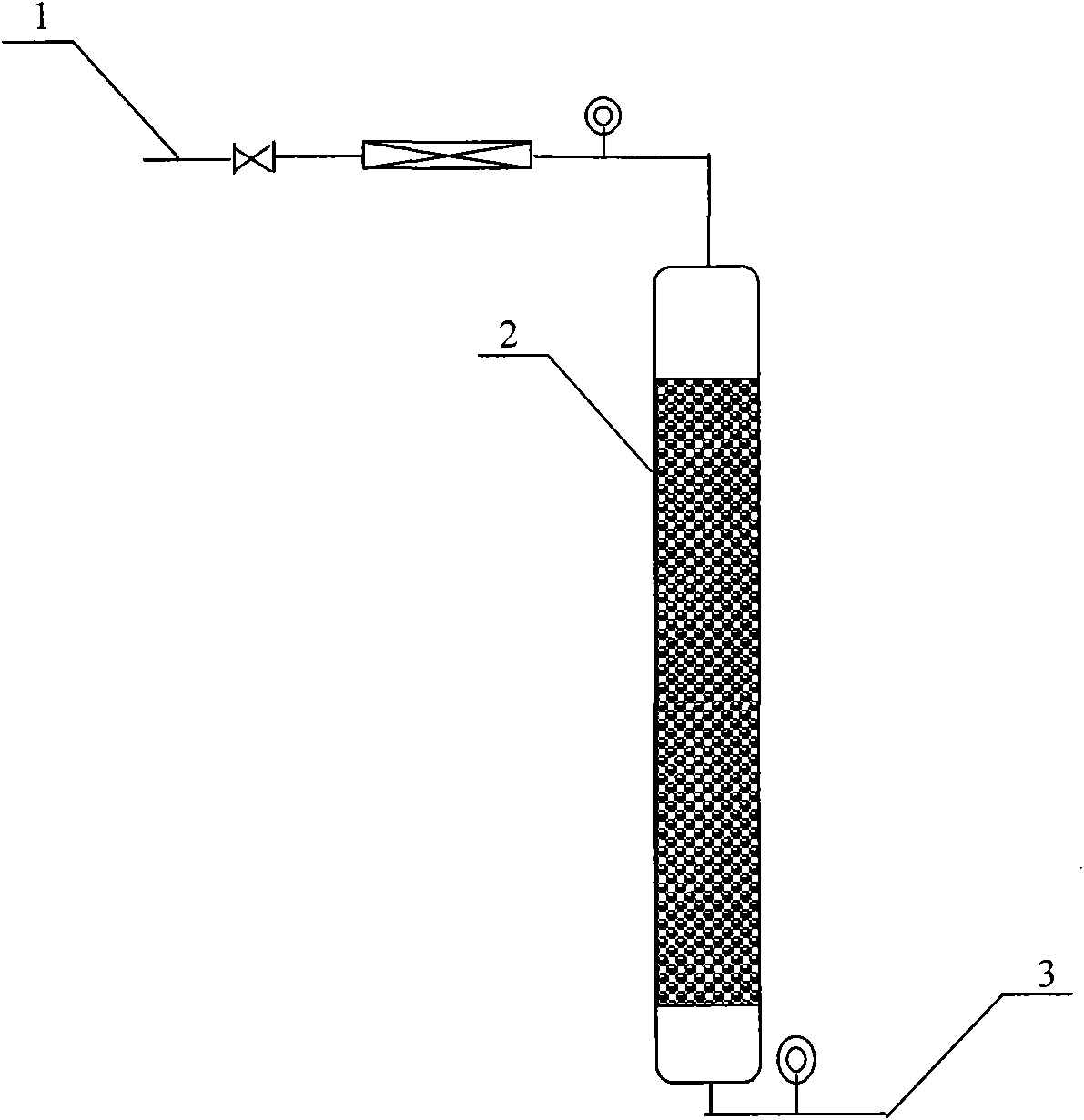

Image

Examples

Embodiment 1

[0029] Example 1: Preparation of iron-manganese-aluminum composite oxide / zeolite antimony adsorbent: Weigh 27.8g FeSO 4 ·7H 2 O, 5.27g KMnO 4 , 24.3gAl 2 (SO 4 ) 3 ·7H 2 O, respectively dissolved in 500ml of water. m Fe :m Mn 3:1, m Al :m Mn is 3:2, (m Fe +m Al ):m OH - It is 1:1. Dissolve 6g NaOH in the potassium permanganate solution, then add the mixed solution of ferrous sulfate and aluminum sulfate, stir 200g zeolite (BET 200m 2 / g, 60 mesh or more) was added to the mixture, continued to stir for 30 minutes, then stood still and aged at room temperature for 16 hours. After aging, skim off the supernatant, then add a small amount of dilute sodium hydroxide solution to neutralize to neutral, then add 1000ml deionized water, stir and wash for 15 minutes, perform solid-liquid separation by filtration, and continue to add solid adsorbent Wash 4 times with deionized water, separate the adsorbent, put it in an oven and bake it at 50-55°C for 3 hours, then raise th...

Embodiment 2

[0031] Example 2: Preparation of iron-manganese-aluminum composite oxide / zeolite antimony adsorbent: Weigh 19.1g FeCl 2 4H 2 O, 5.27g KMnO 4 , 22.9gAlCl 3 ·6H 2 O, respectively dissolved in 500ml of water. m Fe :m Mn 3:1, m Al :m Mn is 3:2, (m Fe +m Al ):m OH - It is 1:1. Dissolve 6g NaOH in the potassium permanganate solution, then add the mixed solution of ferrous chloride and aluminum chloride, stir 300g zeolite (BET 170m 2 / g, 30 mesh or more) was added to the mixture, continued to stir for 45 minutes, then stood still and aged at room temperature for 24 hours. After aging, skim off the supernatant, then add a small amount of dilute sodium hydroxide solution to neutralize to neutral, then add 1000ml deionized water, stir and wash for 15 minutes, perform solid-liquid separation by filtration, and continue to add solid adsorbent Wash 4 times with deionized water, separate the adsorbent, put it in an oven and bake it at 50-55°C for 3 hours, then raise the temper...

Embodiment 3

[0033] Example 3: Preparation of iron-manganese-aluminum composite oxide / zeolite antimony adsorbent: Weigh 27.8g FeSO 4 ·7H 2 O, 5.27g KMnO 4 , 22.9gAlCl 3 ·6H 2 O, respectively dissolved in 600ml of water. m Fe :m Mn 3:1, m Al :m Mn is 3:2, (m Fe +m Al ):m OH - It is 1:1. Dissolve 6g NaOH in the potassium permanganate solution, then add the mixed solution of ferrous chloride and aluminum chloride, stir 260g zeolite (BET 230m 2 / g, 60 mesh or more) was added to the mixture, continued to stir for 1 hour, then stood still and aged at room temperature for 24 hours. After aging, skim off the supernatant, then add a small amount of dilute sodium hydroxide solution to neutralize to neutral, then add 800ml of deionized water, stir and wash for 15 minutes, perform solid-liquid separation by filtration, and continue to add solid adsorbent Wash 4 times with deionized water, separate the adsorbent, put it in an oven and bake it at 45-55°C for 2 hours, then raise the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com