Use of mercapto-functional silicon dioxide hollow microsphere as mercury ion adsorbing agent

A silica and thiol functional technology, applied in the direction of adsorption of water/sewage treatment, inorganic chemistry, silicon compounds, etc., can solve the problems of destroying enzymes and re-synthesis of other protein functions, and achieve superior adsorption performance and large adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

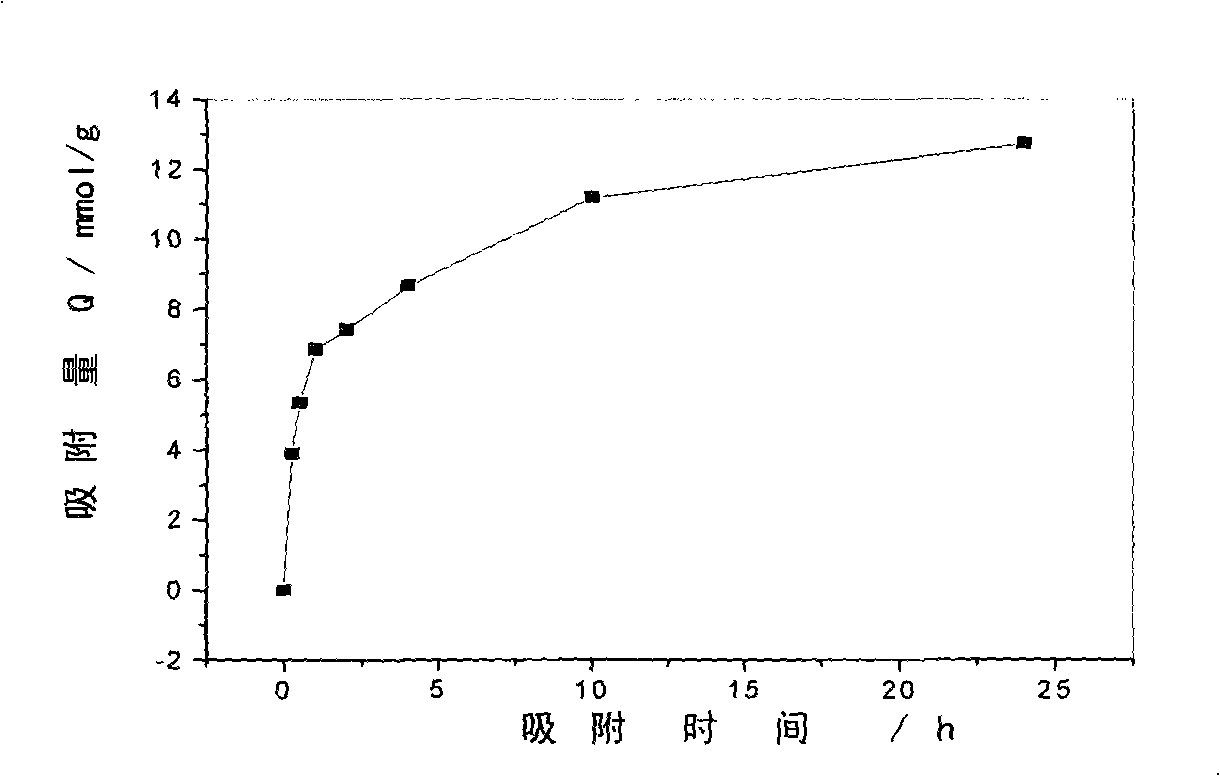

[0021] Take 0.2g of thiol-functionalized silica hollow microsphere suspension with a shell thickness of 20nm and uniformly disperse it by ultrasonic, add it to a 100ml conical flask, pipette 20.00ml of mercury standard stock solution, add into a Erlenmeyer flask, ultrasonically dispersed and shaken, and set aside. At 24 hours after mixing, suction filtration was performed, and then the filtrate was collected to measure the concentration of mercury ions. The Hg in the diluted filtrate was measured by the Italian DMA-80 mercury measuring instrument 2+ Through calculation, the adsorption capacity of mercapto-functionalized silica hollow microspheres to mercury ions is 2558.7 mg / g.

Embodiment 2

[0023] The adsorption time was 4 hours, and the remaining conditions were the same as in Example 1, and the Italian DMA-80 mercury measuring instrument was used to measure Hg in the diluted filtrate clear liquid. 2+ The concentration of mercapto-functionalized silica hollow microspheres was calculated, and the measured adsorption amount of mercury ions was 1738.7 mg / g.

Embodiment 3

[0025] Take 0.2g of thiol-functionalized silica hollow microsphere suspension with a shell thickness of 10nm and uniformly disperse it by ultrasonic, add it to a 100ml conical flask, pipette 20.00ml of mercury standard stock solution, add into a Erlenmeyer flask, ultrasonically dispersed and shaken, and set aside. At 24 hours after mixing, suction filtration was performed, and then the filtrate was collected to measure the concentration of mercury ions. The Hg in the diluted filtrate was measured by the Italian DMA-80 mercury measuring instrument 2+ Through calculation, the adsorption capacity of mercapto-functional silica hollow microspheres to mercury ions is 3477 mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com