Modified and sulfur-impregnated molecular sieve demercuration agent, and preparation method and special apparatus thereof

A technology for sieving a mercury remover and a molecular sieve, which is applied to the field of modified impregnated sulfur molecular sieve mercury remover and its preparation, can solve the problems of increasing the contact probability of mercury and the limited effect of adsorbing mercury, and achieves fast adsorption speed, developed pore structure, and good quality. The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

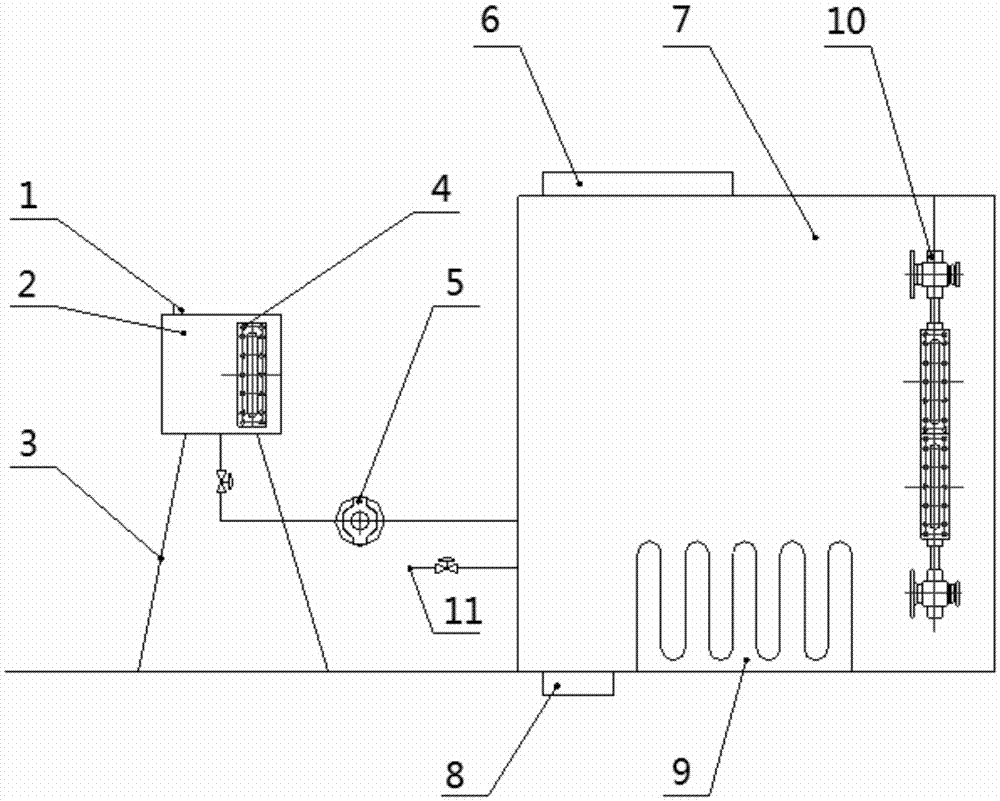

Image

Examples

Embodiment

[0031] In this embodiment, the carbonized walnut shell is used as a molecular sieve. The molecular sieve has the properties of developed pore structure, fast adsorption speed, high adsorption capacity, and easy regeneration. Carbonized walnut shells were used as molecular sieves, and impregnated with sulfur (industrial grade). By changing different preparation processes, it was found that the sulfur-loaded molecular sieves prepared under the following conditions had high sulfur loading and good mercury removal effects, and could not only be used in low temperature environments. , and is less affected by water, the specific preparation process is as follows:

[0032] (1) Put the walnut shells into the furnace at 982°C for carbonization through the transmission belt at a speed of 13.61kg / h, and the residence time of the walnut shells is 30 minutes.

[0033] (2) Continuous nitrogen purification in the opposite direction (countercurrent), maintained at 25Nft3 / min (SCFM) (0.70792Nm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com