Wet method flue gas-desulfurizing absorption tower with dual speed sprinkling and desulfurizing absorption method thereof

A wet desulfurization and absorption tower technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., to save energy, strengthen reaction effects, and reduce power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

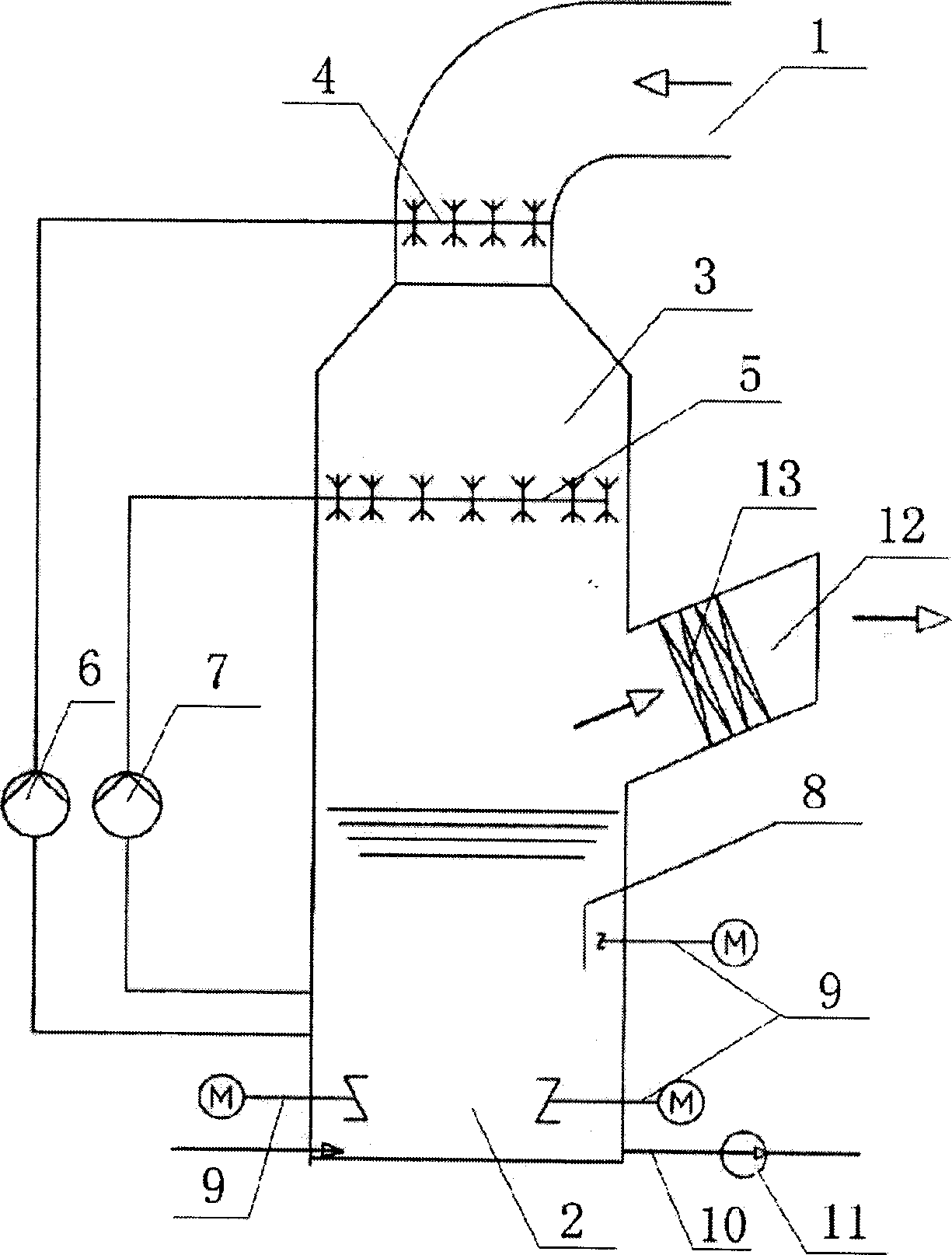

[0022] Embodiment one sees figure 1 , this kind of double-speed spray flue gas wet desulfurization absorption tower, the top of the tower body is connected with the raw smoke inlet pipe 1, the bottom of the tower body is the slurry pool 2, the middle part of the tower body is the desulfurization reaction section 3, and the desulfurization reaction section is connected with the clean smoke The outlet pipe 12 is connected, and the demister 13 is set in the clean smoke outlet pipe 12; the first-stage spraying device 4 is installed at the entrance of the raw smoke inlet pipe on the top of the tower body, and the nozzles of the above-mentioned spraying device are sprayed in two directions up and down. Hollow cone two-way nozzle for limestone slurry. The first-stage spraying device communicates with the slurry pool 2 through the first circulating pump 6, and the second-stage spraying device 5 is installed above the clean smoke outlet pipe in the middle of the tower body, and the sec...

Embodiment 2

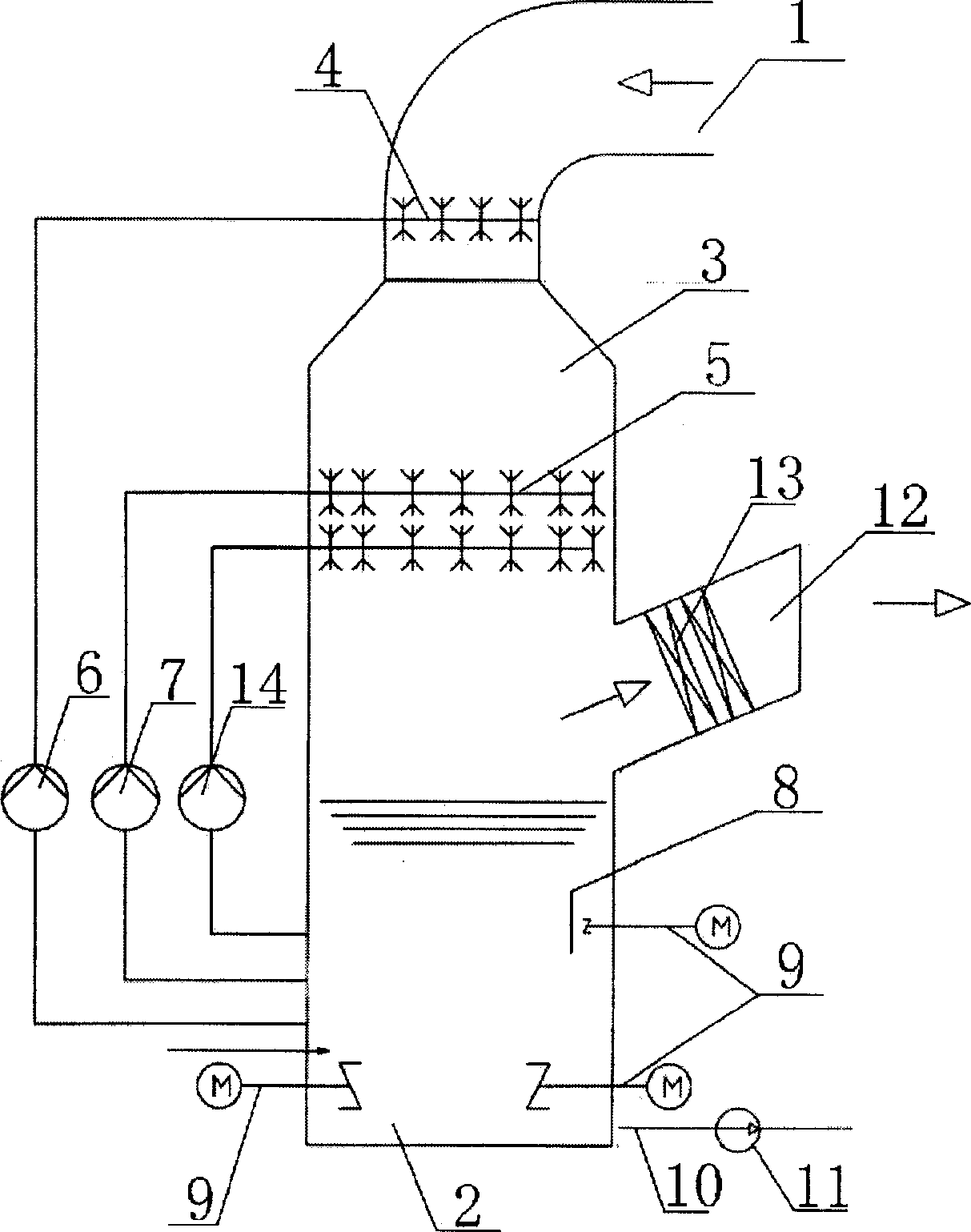

[0044] Embodiment two see figure 2 , The difference from Embodiment 1 is that the second-stage spraying device has two layers, which are respectively connected to the slurry tank through the second circulation pump 7 and the third circulation pump 14 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com