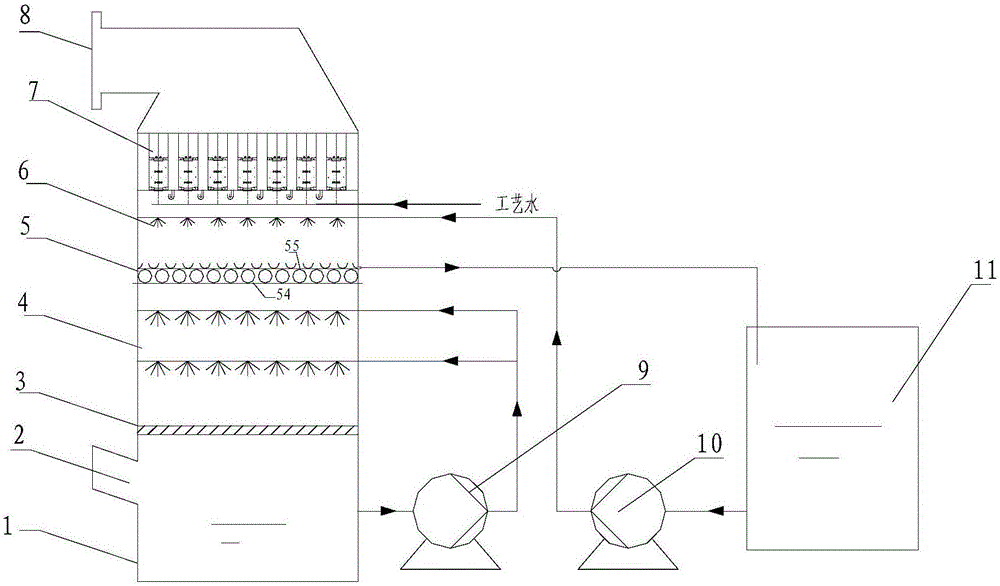

Single-tower and double-circulation desulfurization and dust removal device and technology

A technology of desulfurization, dust removal, and double circulation, which is applied in combination devices, separation methods, and dispersed particle separation. and other problems, to achieve the effect of ensuring the effect of atomization and condensation, optimizing the reaction process, and increasing the contact area of gas and liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

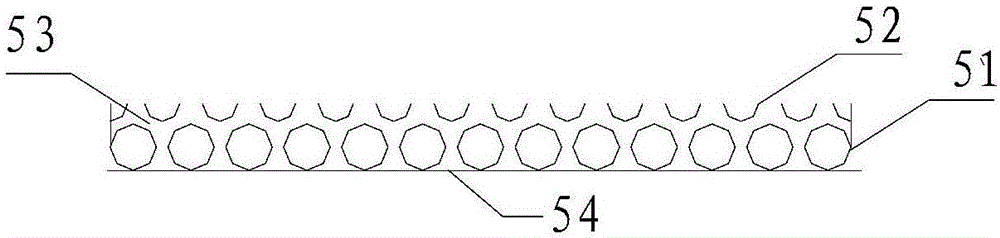

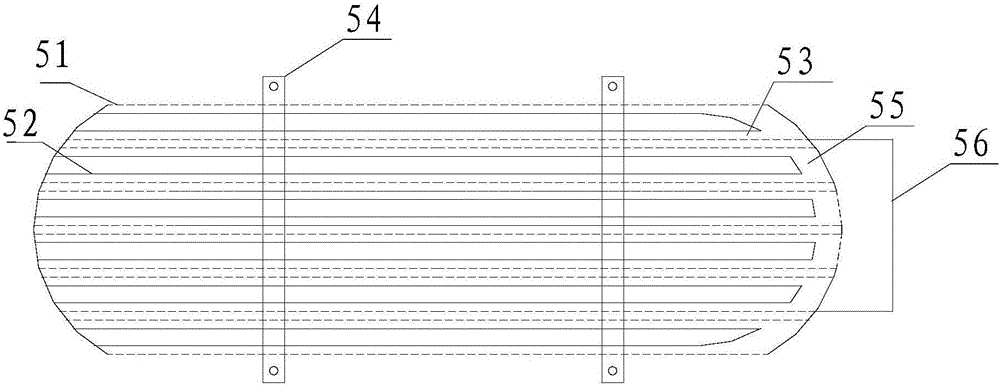

Embodiment 1

[0062] A thermal power plant, two 60WM unit flue gas new desulfurization project adopts this process, the main tower flue gas flow rate is 3.8m / s, the SO in the inlet flue gas 2 The concentration is 1565mg / Nm 3 , the dust concentration in the inlet flue gas is 53mg / Nm 3 , the coarse spray absorption is 2 layers, and the liquid-gas ratio of the inner circulation is 12L / Nm 3 , the pH value of the slurry is 5-5.5; the fine absorption reaction layer is 1 layer, and the liquid-gas ratio of the external circulation is 1.0L / Nm 3 , the pH value of the slurry is 7-8; the resistance of the flue gas passing through the Venturi is 500Pa, the average particle size of the droplet atomization is 42μm, and the diameter of the Venturi rod is 100mm; , the SO in the outlet flue gas 2 The concentration is 11mg / Nm 3 , the desulfurization efficiency reaches 99.3%, and the dust concentration in the outlet flue gas is 3.1mg / Nm 3 .

Embodiment 2

[0064] A self-provided electroplating power plant, a 300t / h boiler flue gas desulfurization renovation project adopts this process, the flue gas flow rate of the main tower is 3.5m / s, and the SO in the inlet flue gas 2 The concentration is 1874mg / m 3 , the dust concentration in the inlet flue gas is 67mg / Nm 3 , the coarse spray absorption is 2 layers, and the liquid-gas ratio of the inner circulation is 15L / Nm 3 , the pH value of the slurry is 5.5-5.8; the fine absorption reaction layer is 1 layer, and the liquid-gas ratio of the external circulation is 0.8L / Nm 3 , the pH value of the slurry is 7-8; the resistance of the flue gas passing through the Venturi is 580Pa, the average particle size of the droplet atomization is 38μm, and the diameter of the Venturi rod is 100mm; , the SO in the outlet flue gas 2 The concentration is 18mg / Nm 3 , the desulfurization efficiency reaches 99.0%, and the dust concentration in the outlet flue gas is 3.6mg / Nm 3 .

Embodiment 3

[0066] In a printing and dyeing factory, a 75t / h boiler flue gas desulfurization renovation project adopts this process, the flue gas flow rate in the main tower is 3.6m / s, and the SO in the inlet flue gas 2 The concentration is 1472mg / m 3 , the dust concentration in the inlet flue gas is 47mg / Nm 3 , the coarse spray absorption is 2 layers, and the liquid-gas ratio of the inner circulation is 13L / Nm 3 , the pH value of the slurry is 5.5-5.8; the fine absorption reaction layer is 1 layer, and the liquid-gas ratio of the outer circulation is 1.0L / Nm 3 , the pH value of the slurry is 7-8; the resistance of the flue gas passing through the Venturi is 550Pa, the average particle size of the droplet atomization is 36μm, and the diameter of the Venturi rod is 100mm; , the SO in the outlet flue gas 2 The concentration is 10mg / Nm 3, the desulfurization efficiency reaches 99.3%, and the dust concentration in the outlet flue gas is 2.8mg / Nm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com