Novel technology for concentrating post-MTBE C4

A new process technology of C4 after ether is applied in the field of extraction and rectification of butene and butane, which can solve the problems of complicated four-column process, uneconomical, low butene yield, etc., so as to improve the extraction and absorption effect and reduce the Energy consumption, the effect of improving the absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

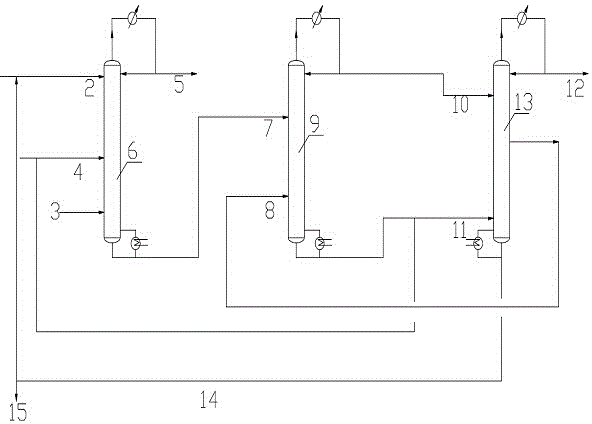

Image

Examples

Embodiment 1

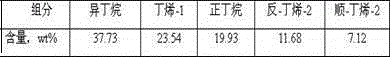

[0032] Table 2

[0033]

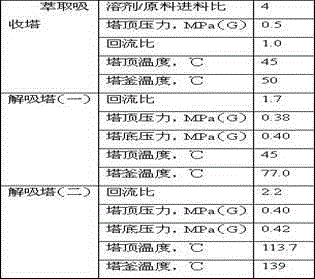

[0034] table 3

[0035]

Embodiment 2

[0037] Absorbent 1 and absorbent 2 contain dimethyl sulfoxide with a mass content of 65% to 80% and 10% to 25% respectively, and the balance is morpholine and N-formylmorpholine, and morpholine and N-formylmorpholine The mass ratio of acylmorpholine is 1:2. The volume ratio of the first mixed absorbent to the second mixed absorbent is 1:1~1:30, and the mass ratio of the bottom material of desorption tower 1 as absorbent 2 to the lower part of desorption tower 2 is 1:4 . Both the extraction and absorption tower and the desorption tower are packed towers, the number of theoretical plates of the extraction and absorption tower is 22, the number of theoretical plates of desorption tower 1 is 10, and the number of theoretical plates of desorption tower 2 is 15. The introduction position of absorbent 1 is the 6th layer from top to bottom of the extraction absorption tower, the introduction position of absorbent 2 is the 11th layer from top to bottom of the extraction absorption tow...

Embodiment 3

[0043] Using the double absorbent extraction and absorption process and the secondary desorption process of the present invention, the C4 raw material in Table 1 is taken from the lower part of the extraction absorption tower, and the first absorbent is morpholine, sulfolane containing 50wt% and a mass ratio of 1:1. For the mixture of N-formylmorpholine, the second absorbent is a mixture of 25wt% sulfolane and morpholine and N-formylmorpholine with a mass ratio of 1:1. After being absorbed by the absorption tower and desorbed by the desorption tower, the C4 The purification of raw material, the operating conditions of absorption tower, desorption tower 1, desorption tower 2 are identical with embodiment 1. The separation results are shown in Table 6.

[0044] Table 6

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com