Gas absorption purifier

A purification device and gas absorption technology, which is applied to chemical instruments and methods, the use of liquid separation agents, and the separation of dispersed particles, which can solve the problems of huge investment, large volume, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

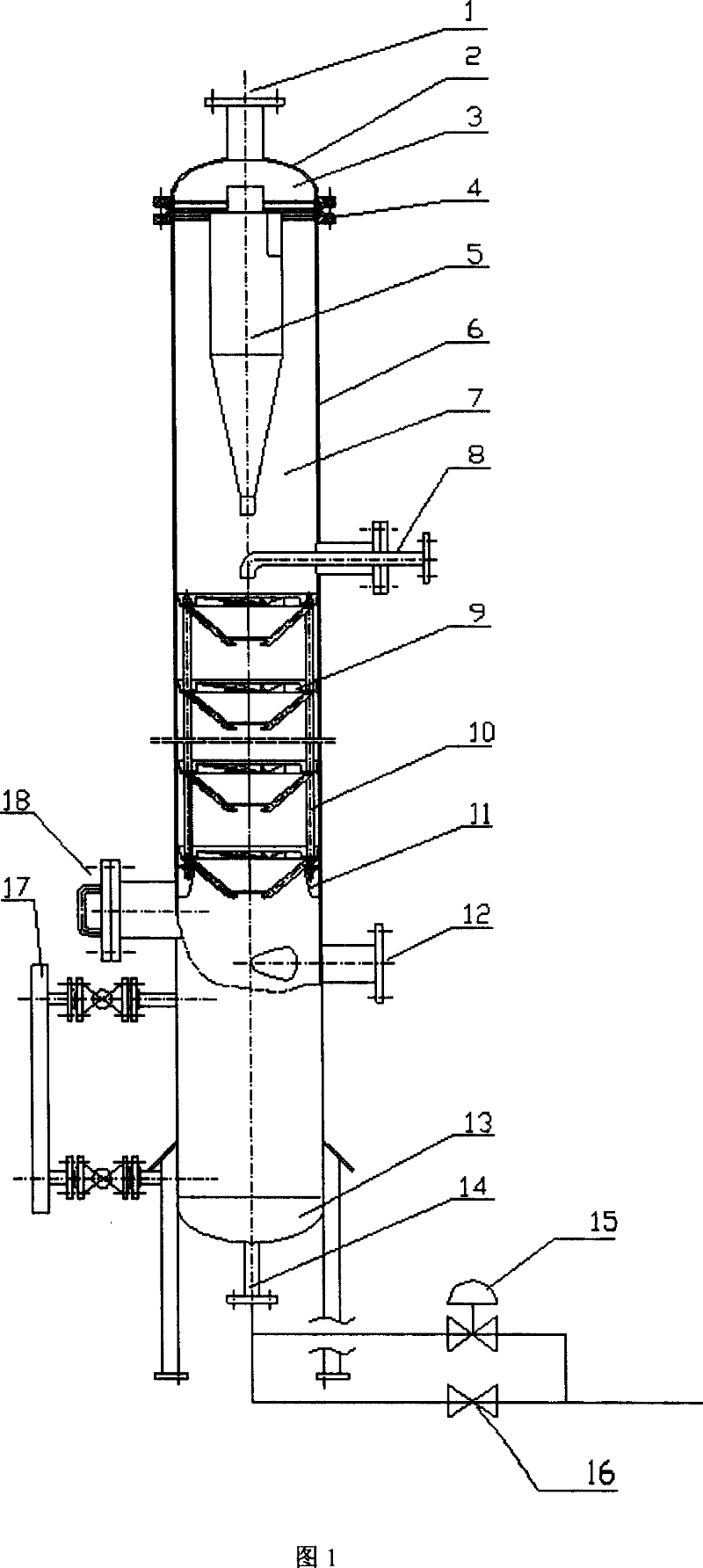

[0023] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

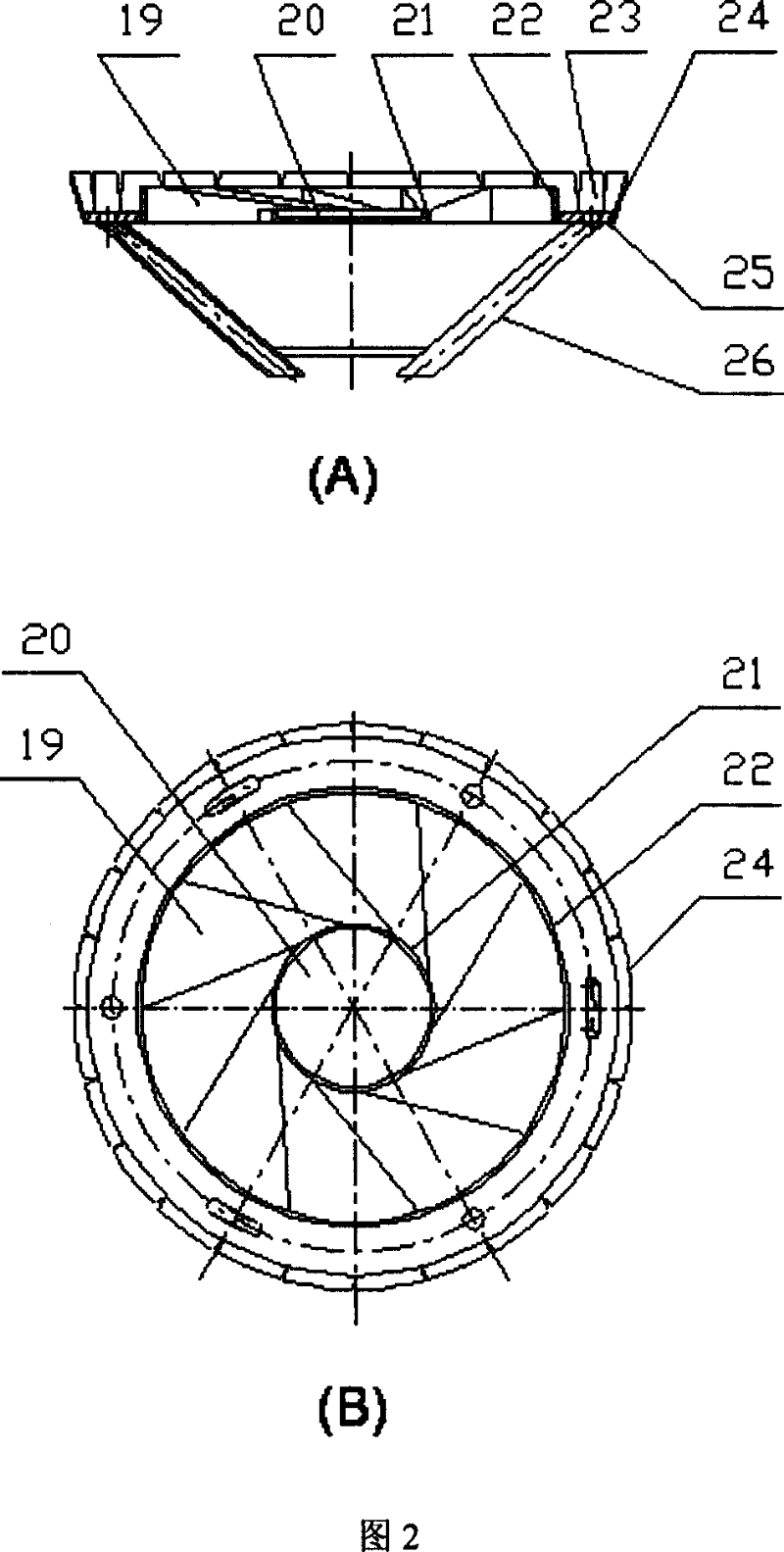

[0024] The present invention is composed of three cavities: a gas collecting chamber (3), a main chamber (7) and a liquid collecting chamber (13). The main chamber (7) has a foam catcher (5) and several deflectors (9); The mist catcher (5) is installed on the upper part of the main cavity; the deflector (9) is fixed by the distance tube (10) and connected into a group, and supported on the built-in ear seat (11); the top cover of the tower body passes through The flange (4) is connected to the tower body (6); there is an exhaust port (1) on the top of the tower; the upper side of the main chamber (7) has an absorption liquid inlet (8), and the lower side has a hand hole (18), an air inlet Mouth (12), the bottom is liquid collecting cavity (13).

[0025] The mist catcher is a cyclone separator, its air inlet and liquid discharge port are in the main cavity, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Cone angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com