Synergistic treatment device for dust removing and desulphurization

A technology of cooperative processing and demisting device, which is applied in the direction of dispersed particle separation, chemical instruments and methods, and the use of liquid separation agents, can solve the problems of poor dust removal effect, achieve low liquid-gas ratio, high-efficiency desulfurization and dust removal, and reduce Effect of investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

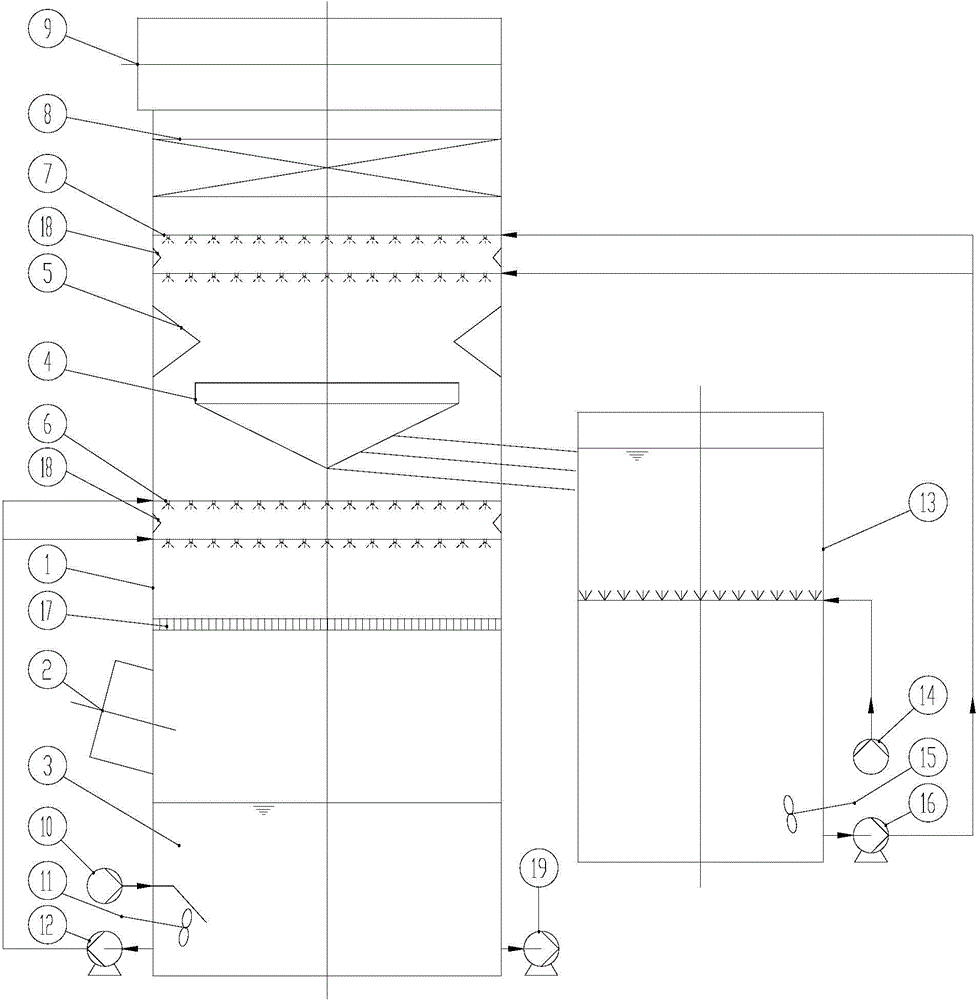

[0016] refer to figure 1 It is an embodiment of a dust removal and desulfurization co-processing device of the present invention. A dust removal and desulfurization co-processing device includes a tower body 1, a flue gas inlet 2 is provided at the lower part of the tower body 1, and a flue gas inlet 2 is provided at the top of the tower body 1. Outlet 9, the tower body 1 is provided with a first-level flue gas dedusting and desulfurization area, a second-level flue gas dedusting and desulfurization area and a demisting device 8 in sequence according to the flue gas flow direction;

[0017] The primary flue gas dedusting and desulfurization zone includes a porous distribution plate 17, a synergistic ring 18 and at least two primary spray layers 6. The porous distribution plate 17 is arranged in the tower body 1 above the flue gas inlet 2, and a The first-level spray layer 6 is arranged in the tower body 1 above the porous distribution plate 17, and a synergistic ring is arrang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com