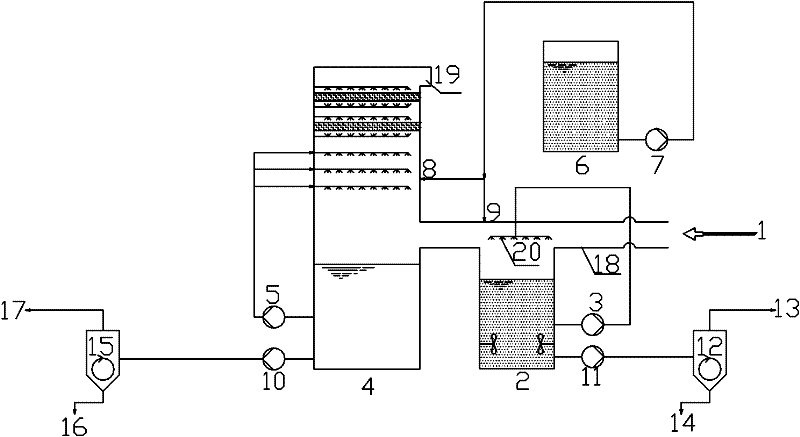

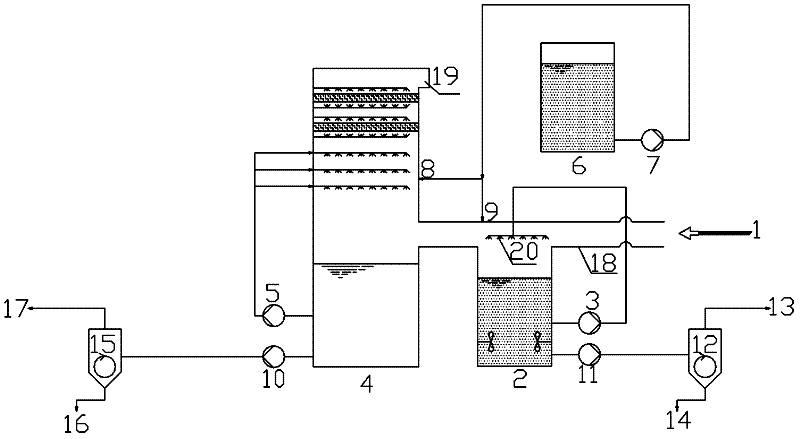

Sintering machine flue gas desulfurization process and device thereof

A desulfurization device, sintering machine technology, applied in the direction of calcium/strontium/barium sulfate, the use of liquid separation agent, the separation of dispersed particles, etc., can solve the problems of dust clogging equipment, inability to achieve desulfurization separation, increasing flue gas resistance, etc. The effect of prolonging service life, saving water consumption and improving desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A steel group 2×180m 2 The flue gas of the sintering machine adopts the wet limestone-gypsum desulfurization process. The pH value of the washing liquid in the flue gas washing tank is controlled at 2.5-2.8, and the residence time of the flue gas in the spray washing section is 2 seconds. The liquid-gas ratio is 3L / m 3 , the pH value of the absorption tower slurry is controlled at 5.2-5.5, and the amount of defoamer in the flue gas washing tank is 5g / m 3 d, entrance SO 2 Concentration is 3700mg / m3, export SO 2 The concentration is 81mg / m 3 , the liquid-gas ratio of the absorption tower is 8L / m 3 . The purity of the gypsum is greater than 97%, the residual calcium carbonate in the gypsum is less than 0.01%, and the Fe content is less than 0.02%.

Embodiment 2

[0039] A steel group 2×120m 2 The flue gas of the sintering machine adopts the wet limestone-gypsum desulfurization process, the pH value of the washing liquid in the flue gas washing tank is controlled at 2.5-3.0, and the residence time of the flue gas in the spray washing section is 1.8 seconds. The liquid-gas ratio is 5L / m 3 , the pH value of the absorption tower slurry is controlled at 5.2-5.6, and the amount of defoamer in the flue gas washing tank is 8g / m 3 d, entrance SO 2 The concentration is 4600mg / m 3 , export SO 2 The concentration is 113mg / m 3 , the liquid-gas ratio of the absorption tower is 10L / m 3 . The purity of the gypsum is as high as 96%, the residual calcium carbonate in the gypsum is less than 0.02%, and the Fe content is less than 0.03%.

Embodiment 3

[0041] A steel group 2×320m 2 The flue gas of the sintering machine adopts the wet limestone-gypsum desulfurization process, the pH value of the washing liquid in the washing tank is controlled at 2.5-2.7, the residence time of the flue gas in the spray washing section is 1.7 seconds, and the liquid-gas ratio of the flue gas washing is 5L / m 3 , the pH value of the absorption tower slurry is controlled at 5.2-5.5, and the amount of defoamer A in the washing tank is 10g / m 3 d, entrance SO 2 The concentration is 3900mg / m 3 , export SO 2 The concentration is 96mg / m 3 , the liquid-gas ratio of the absorption tower is 7L / m 3 . The purity of the gypsum is greater than 96%, the residual calcium carbonate in the gypsum is less than 0.01%, and the Fe content is less than 0.02%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com