Out tower double circulation desulfurization system and desulfurization process thereof

A desulfurization system and desulfurization process technology, applied in calcium/strontium/barium sulfate, inorganic chemistry, gas treatment, etc., can solve the problems of increasing the failure rate of the desulfurization system, mutual mixing, and reducing the availability of desulfurization devices, so as to ensure the oxidation Sufficient and efficient desulfurization, guaranteed normal operation, intuitive operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

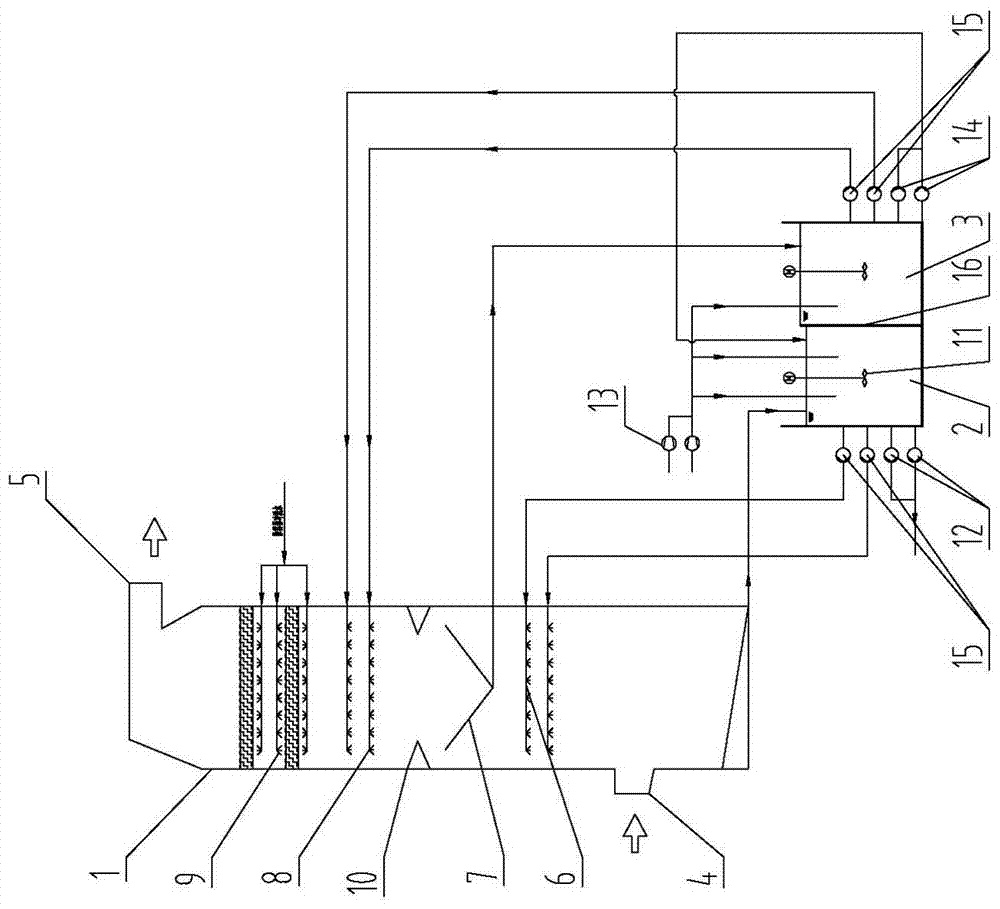

[0020] Example 1, such as figure 1 As shown, the double-circulation desulfurization system outside the tower includes a tower body 1, a low pH slurry tank outside the tower 2, a high pH slurry tank outside the tower 3; a flue gas inlet 4 is provided at the bottom of the tower body 1, and a flue gas is provided at the top of the tower body 1. Gas outlet 5; corresponding to the position between the flue gas inlet 4 and the flue gas outlet 5 in the tower body 1, a low pH spray area 6, a cone-shaped liquid collecting bucket 7, and a high pH spray area are fixedly installed from bottom to top. The spray area 8 and the mist eliminator 9; the bottom of the tower body 1, the low pH spray area 6 are connected to the low pH slurry tank 2 outside the tower, and the high pH spray area 8, the conical sump 7 are connected to The high pH value slurry pool 3 outside the tower is connected; the low pH value slurry pool 2 outside the tower and the high pH value slurry pool 3 outside the tower ar...

Embodiment 2

[0034] Example 2, such as figure 1 As shown, the dual-cycle desulfurization process outside the tower includes the following steps: Step 1: The flue gas enters from the flue gas inlet 4, and the slurry after desulfurization through the low pH spray zone 6 flows from the bottom of the tower body 1 to the tower through the pipeline The low pH value slurry tank 2 outside the outer tower, the design residence time of the slurry in the tank is not less than 4.5 minutes, and it is transported and circulated back to the low pH value spray area 6 through the circulating pump 15 connected to the low pH value spray area 6 ; Step 2: After a step a low pH value spray zone 6 treatment, the flue gas rises through the conical sump 7 and then passes through the high pH value spray zone 8 for desulfurization, the reacted slurry and the demister 9 The flushing water is collected in the conical collecting hopper 7 and flows through the pipeline to the high pH value slurry pool 3 outside the tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com