Substrate stacking structure

A stacking structure and substrate technology, applied in the field of stacking structures, can solve problems such as broken metal wires, difficulty in reducing the thickness of the stacking structure, and difficult independent testing of chips on different platforms, etc., to achieve the effect of reducing the overall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

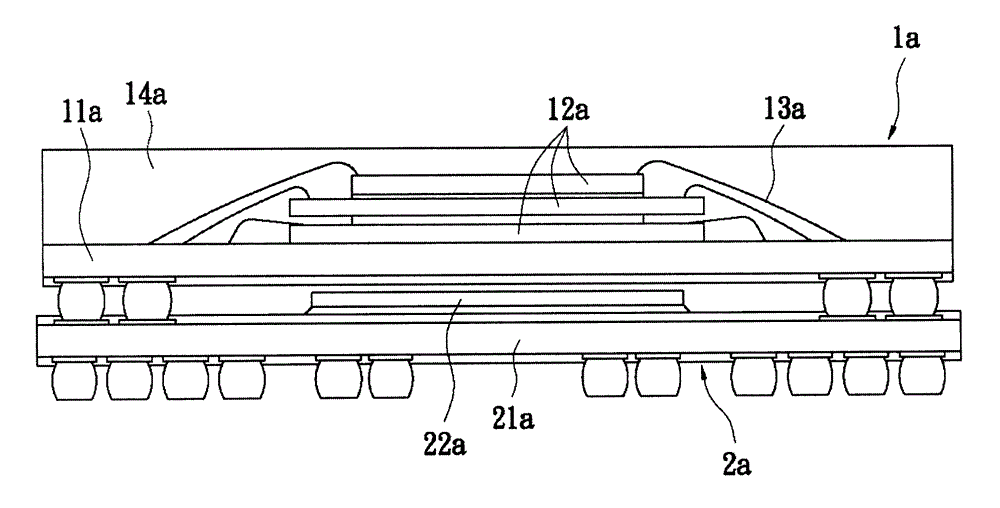

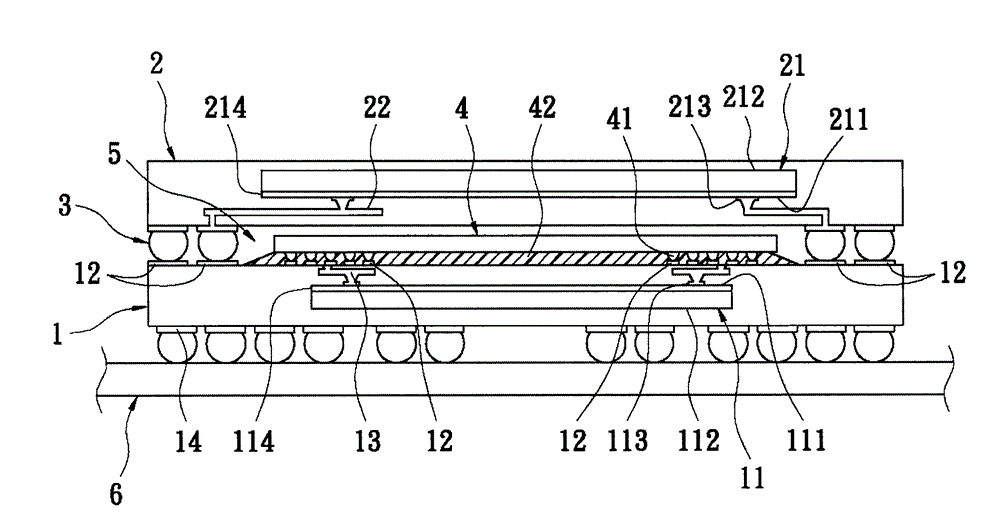

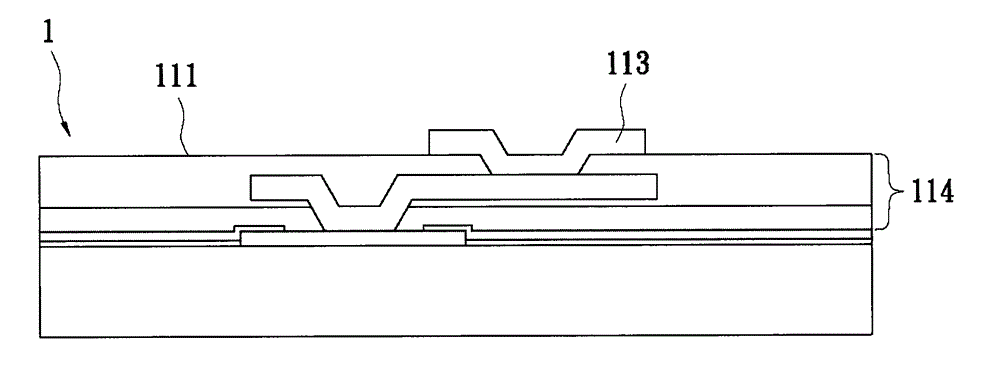

[0056] see figure 2 with image 3 , which is a preferred embodiment of the present invention, where figure 2 It is a schematic diagram of the present invention, image 3 for figure 2 magnified schematic diagram.

[0057] refer to figure 2 , which is a substrate stack structure, including a first substrate (substrate) 1 embedded with a first chip (die) 11, a second substrate (substrate) 2 embedded with a second chip (die) 12, several connections to the above-mentioned The soldering part 3 of the first substrate 1 and the second substrate 2 , and a third die 4 disposed between the first substrate 1 and the second substrate 2 . Wherein, the above-mentioned soldering part 3 conducts the first substrate 1 and the second substrate 2 , and the first substrate 1 , the second substrate 2 and the soldering part 3 surround and form an accommodating space 5 . The third chip 4 is disposed in the accommodating space 5 and bonded to one end surface of the first substrate 1 , and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com