Novel barrier type air-actuated three-phase fluidization synthetized absorbing tower

An absorption tower and three-phase flow technology, which is applied in the field of a new grid-type pneumatic three-phase fluidized comprehensive absorption tower, can solve problems such as increased investment and operating costs, decreased gas-liquid mass transfer efficiency, and uneven gas-liquid distribution. Achieve the effects of reduced operation and maintenance costs, low resistance, and reduced packing layer height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

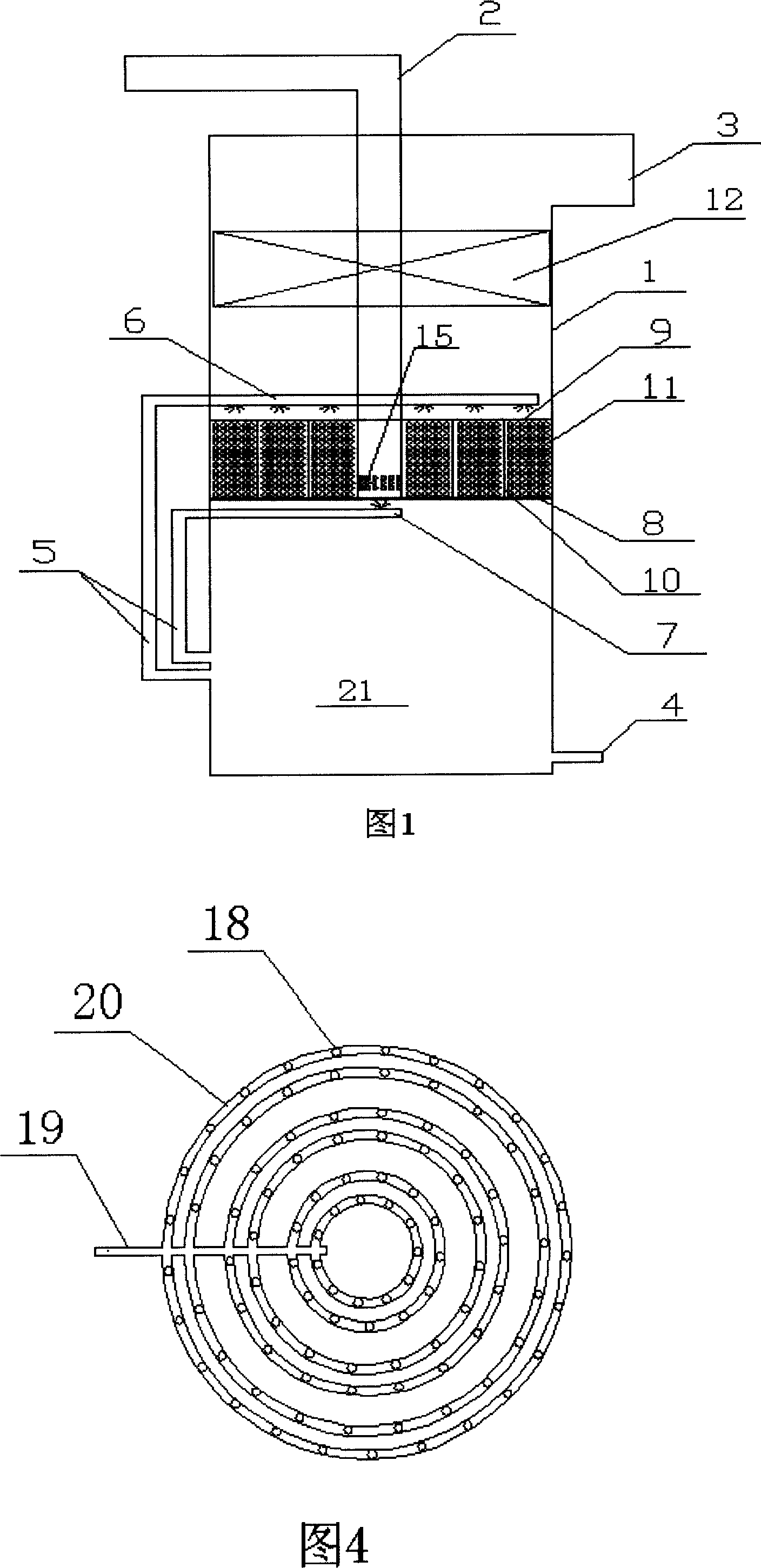

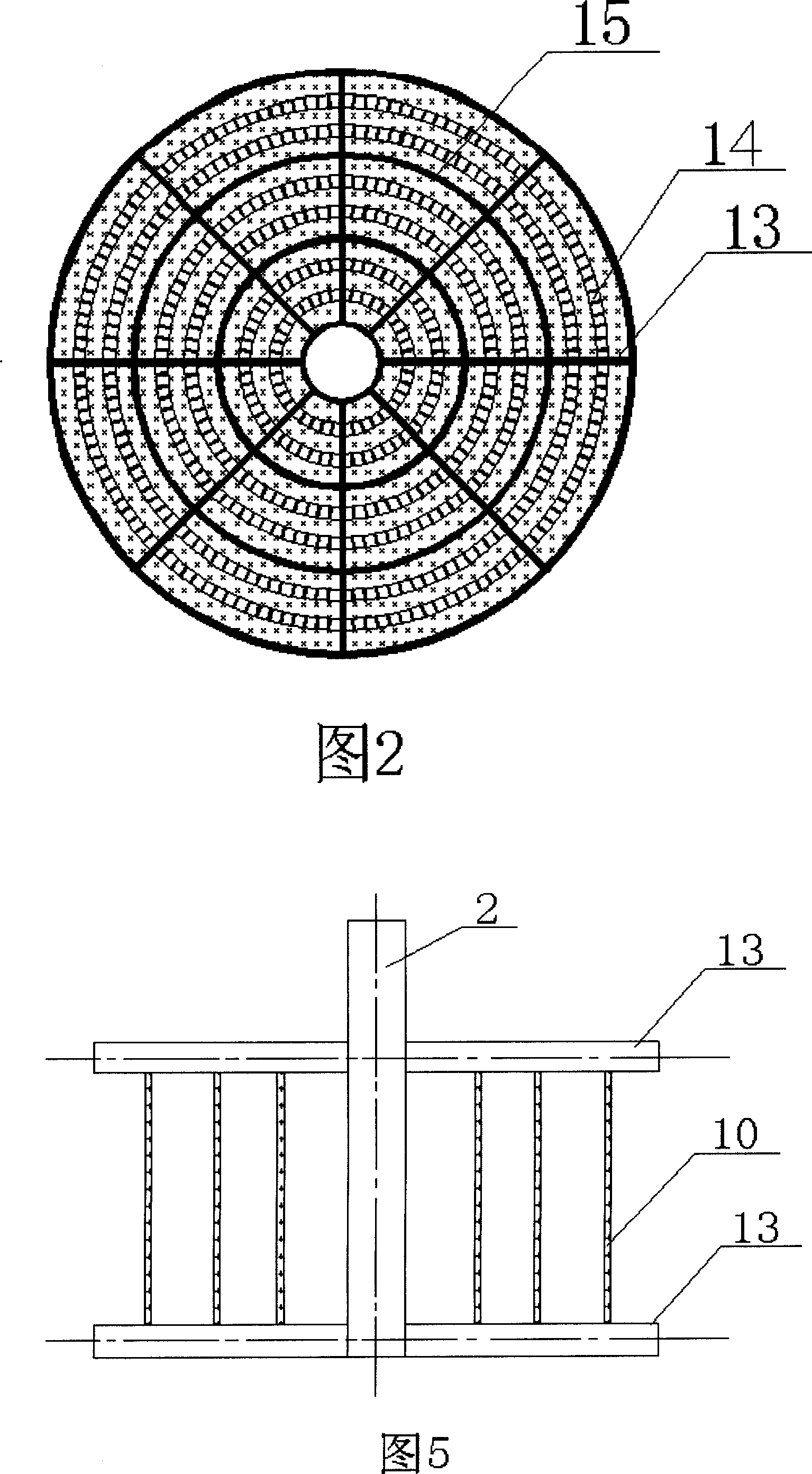

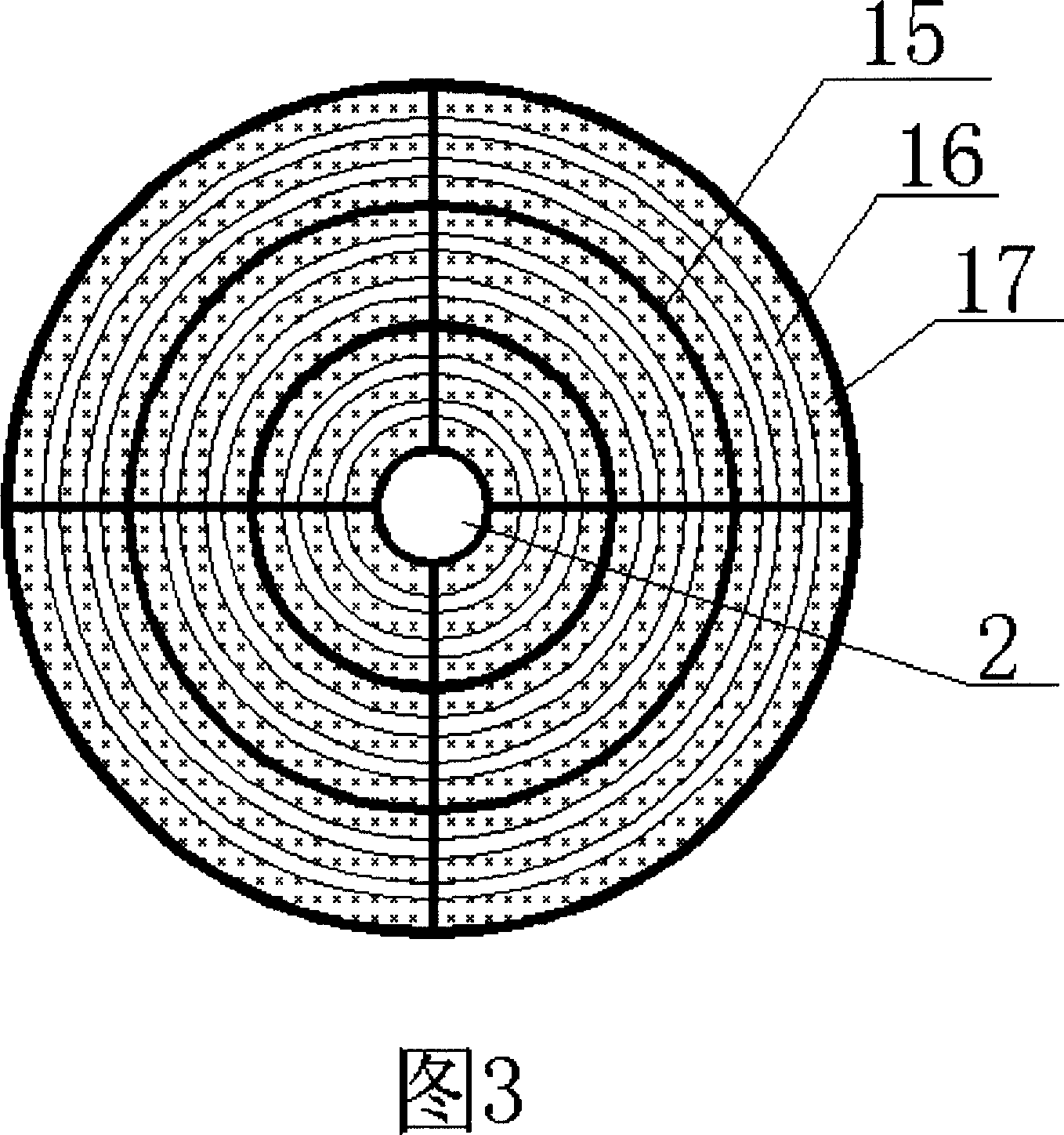

[0031] In Fig. 1, the present invention comprises the absorption tower shell (1), the inlet pipe (2) of the tower top, the gas outlet (3), the rotary demister dehydration device (12) of the upper part in the tower, the filler in the tower The supporting plate (8), packing pressing plate (9) and packing (11), the concentric tubular grille member (10) in the middle of the packing, and the annular spray pipe liquid distribution device (6) on the packing pressing plate (9), carry out The large-diameter reverse injection device (7) in the gas pipeline, and the absorption slurry pool (21) at the bottom of the tower. The raw gas containing pollutants enters the absorption tower from the upper air inlet pipe (2), and at the lower part of the air inlet pipe (2), the original gas collides with the absorption liquid ejected from the slurry reverse injection device (7). The momentum causes the absorbing liquid to scatter and splash, and a stable foam layer (15) is formed at the position w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com