Liquid phase redistributor for spray towers

A technology of redistributor and spray tower liquid, applied in the field of liquid phase redistributor, can solve the problem of uneven distribution, and achieve the effects of reducing the liquid-gas ratio, increasing the utilization rate, and improving the operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention will be further described:

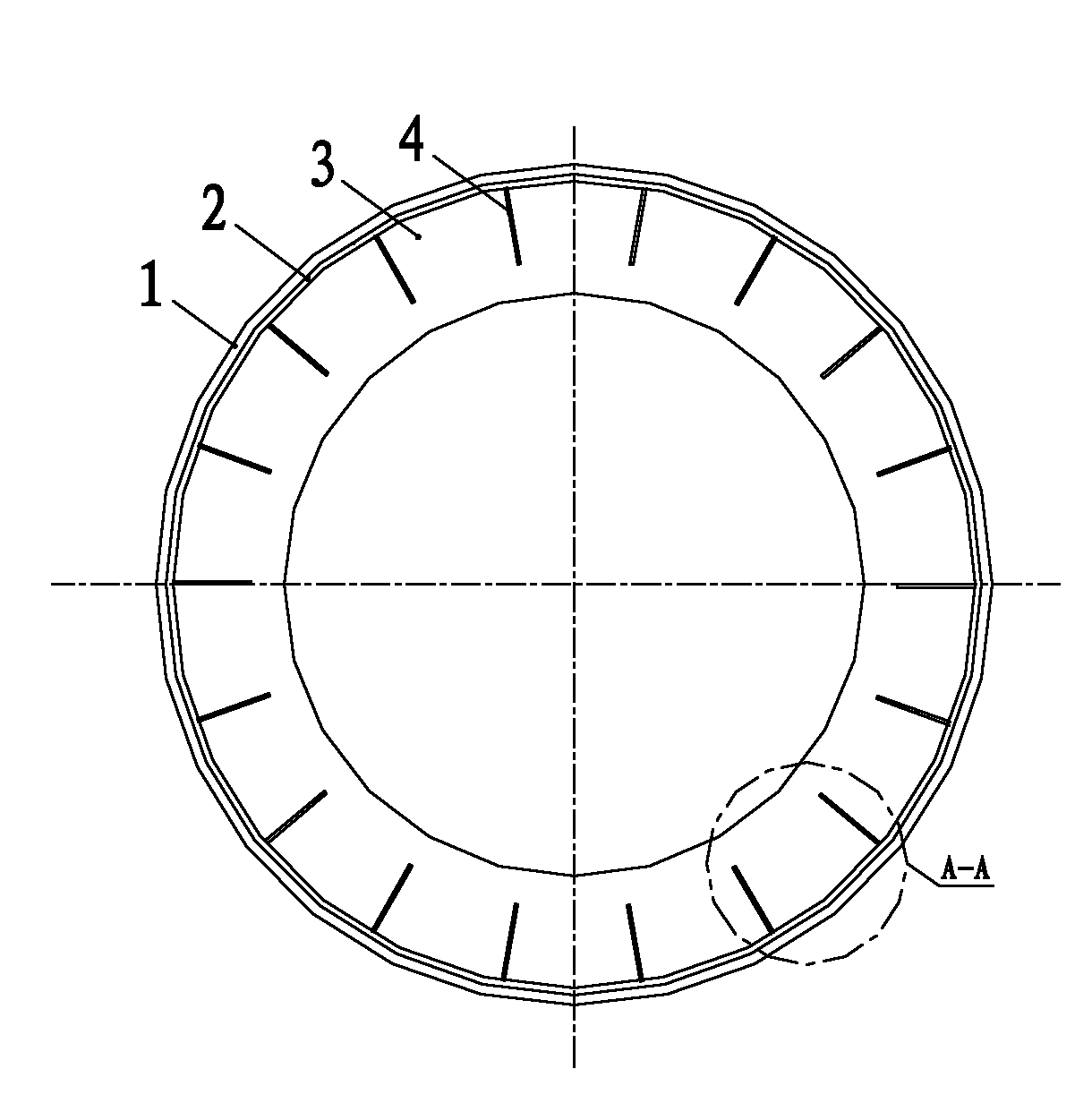

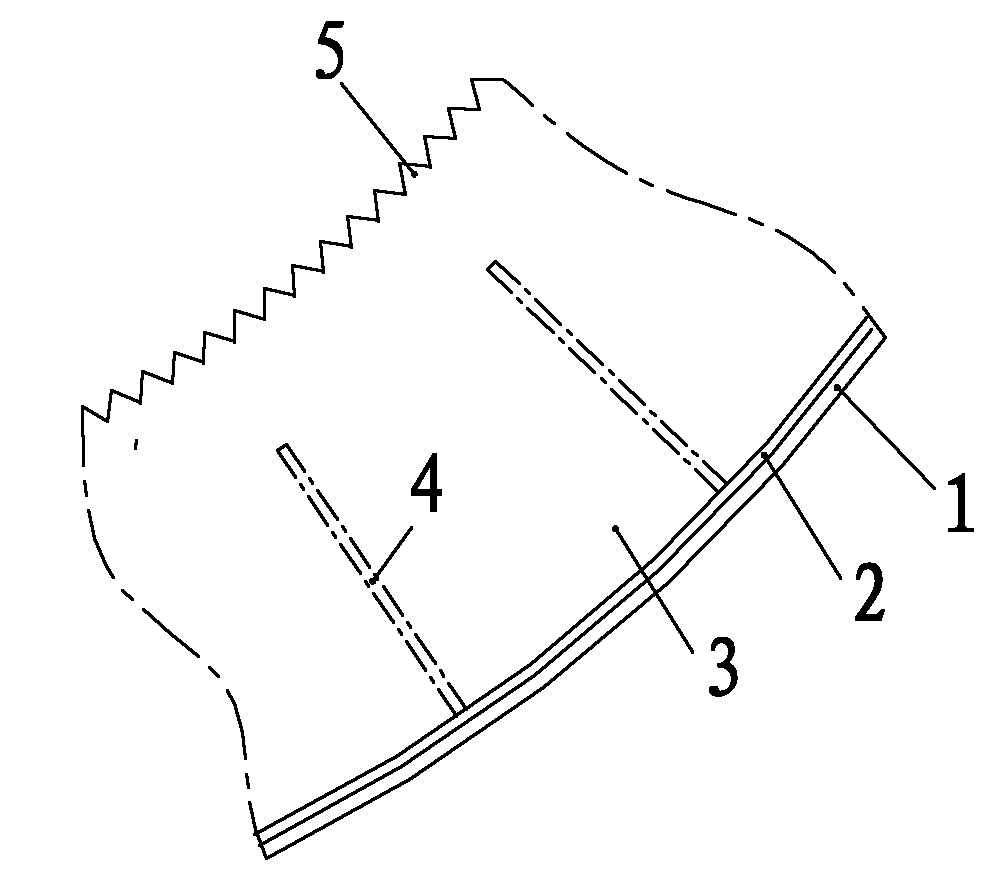

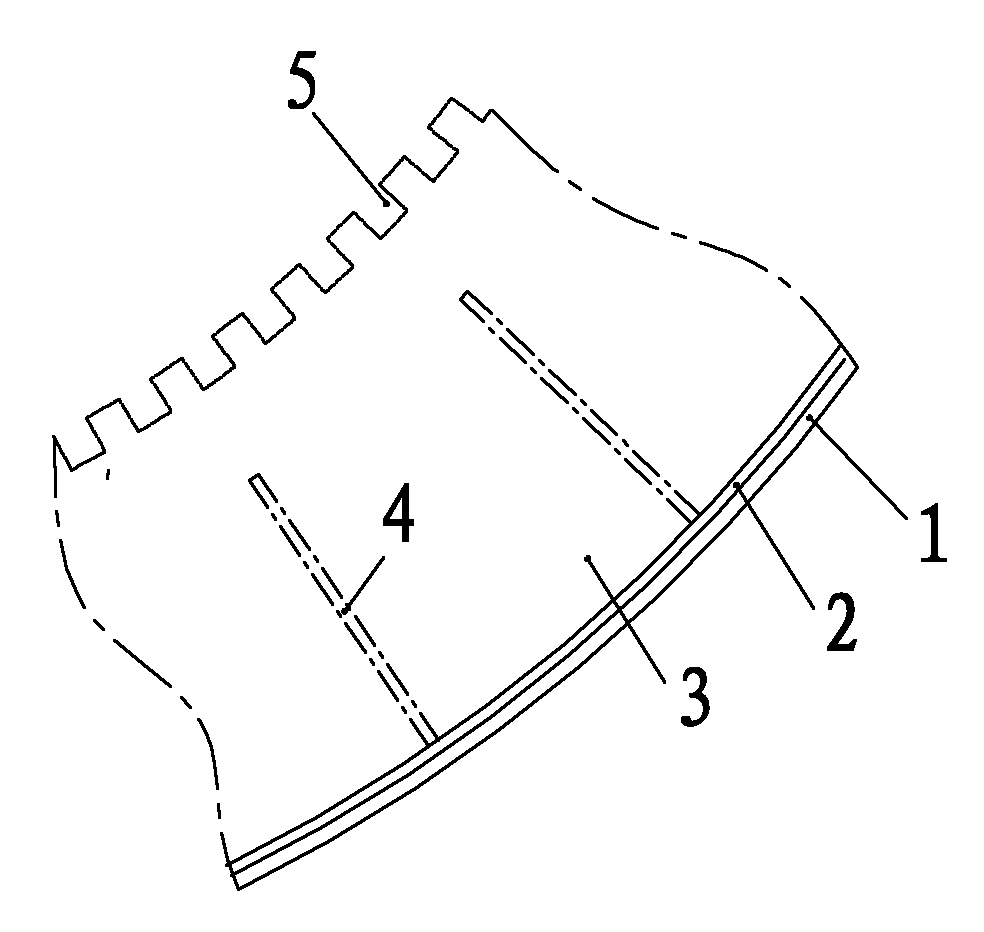

[0025] figure 1 is the top view of the liquid phase redistributor of the spray tower, Figure 5 for figure 1 The side structure diagram of the spray tower liquid phase redistributor includes a distribution plate 3, a support member 4 supporting the distribution plate 3, the distribution plate 3 is ring-shaped, and is installed in a circular line along the spray tower wall 1, and on the tower wall 1 A reinforcing plate 2 is arranged on the top, the annular outer ring of the distribution plate 3 is welded on the tower wall 1 through the reinforcing plate 2, the annular inner ring of the distribution plate 3 is inclined to the bottom of the tower wall 1, and a support 4 is installed on the lower part of the distribution plate 3 to support Part 4 is fixedly connected with reinforcing plate 2. The distribution plate 3 is inclined to the bottom of the tower wall 1, the inclin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com