Device and method for depriving sulfur dioxide in flue gas by using ammonia water

A sulfur dioxide and flue gas technology, applied in chemical instruments and methods, fertilization devices, separation methods, etc., can solve the problems of blowing and collapse of packing, large maintenance workload, and increased flue gas flow rate, etc. The effect of good by-product quality and high desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

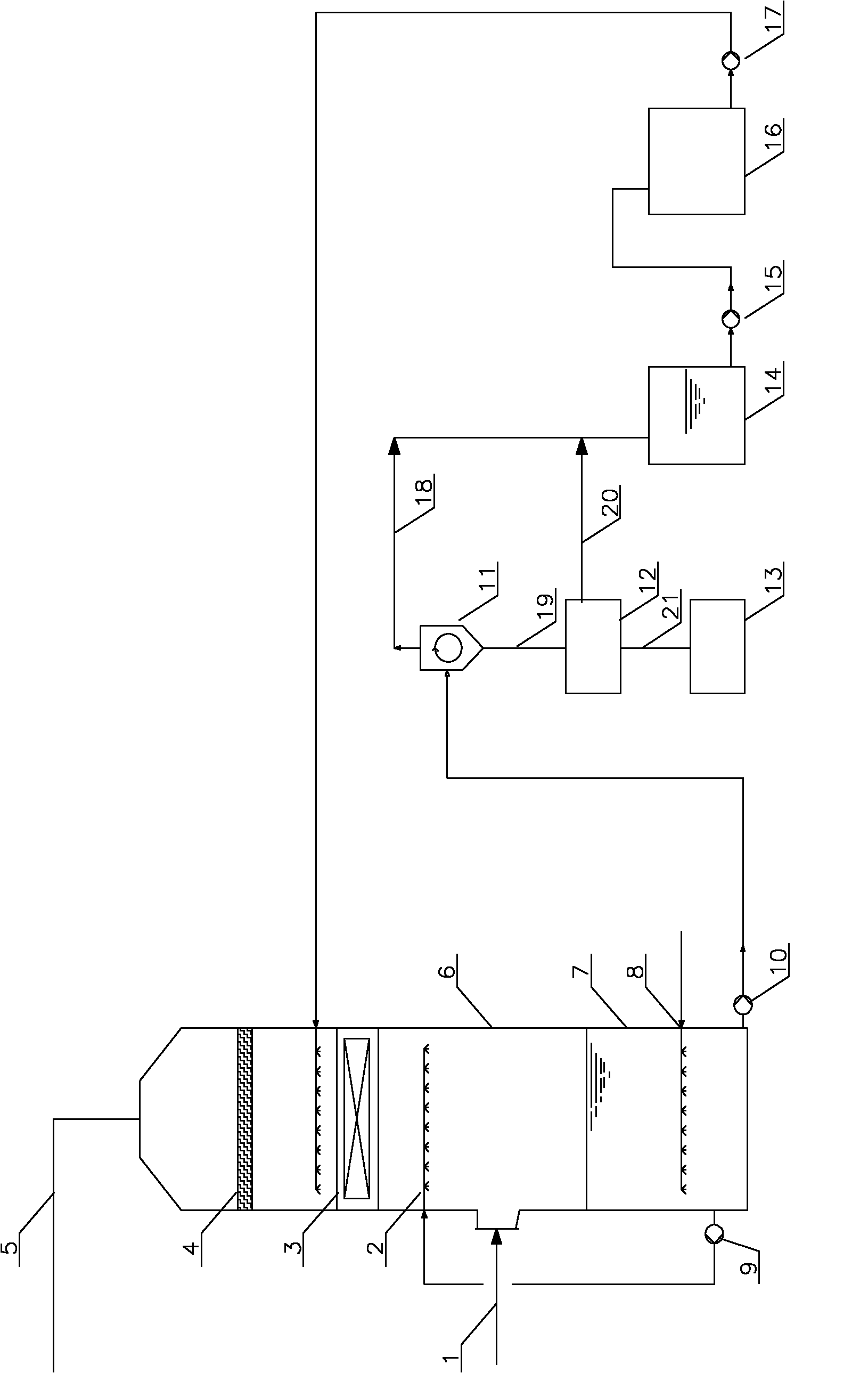

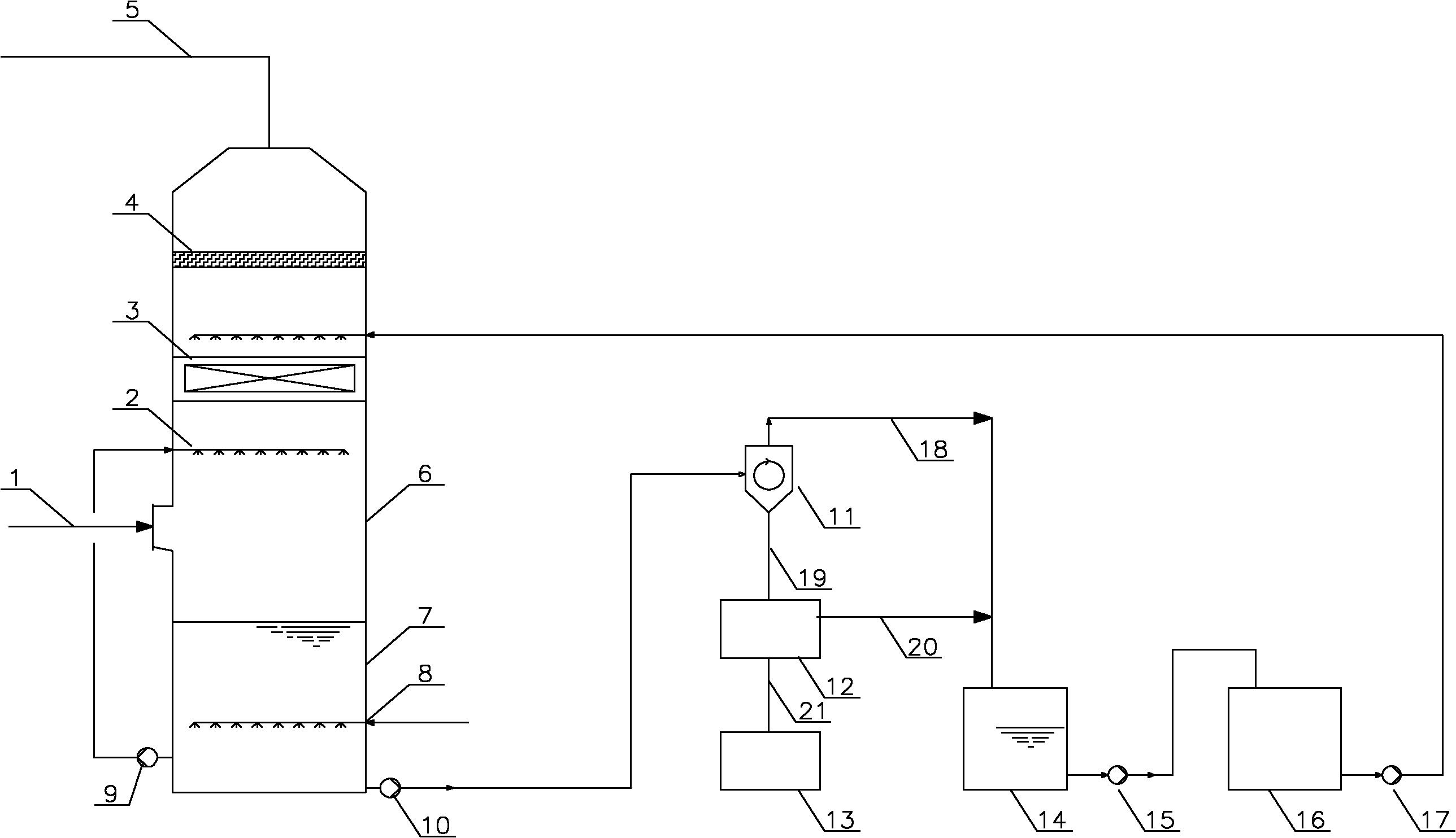

[0024] Such as figure 1 As shown, an ammonia desulfurization absorption tower 6, circulation pump 9, discharge pump 10, cyclone 11, centrifuge 12, dryer 13, filtrate tank 14, filtrate pump 15, online filter 16, clear liquid pump 17. From bottom to top, it includes the tower bottom slurry pool 7 of the absorption tower, the spray layer 2, the packing layer 3, and the demister 4, wherein the spray layer 2 includes two layers of sprayers, and the packing layer 3 is a layer of packing; the absorption The middle part of the tower is located below the spray layer 2, and a flue gas inlet 1 is arranged above the slurry pool 7 at the bottom of the tower, and a flue gas outlet 5 is provided at the top of the absorption tower; the slurry pool 7 of the absorption tower is provided with an aeration pipe 8 The absorption tower 6 is provided with 2 circulation pumps 9 outside, and the outlet of each circulation pump 9 links to each other with the shower in one deck spray layer 2 respectively...

Embodiment 2

[0026]The rest are the same as in Example 1, except that the absorption tower spray layer 2 includes 3 layers of sprayers, and correspondingly, three circulation pumps 9 are correspondingly arranged outside the tower, and the outlet of each circulation pump 9 They are respectively connected to each sprayer in the spraying layer 2, and the inlet of each circulation pump 9 is connected to the slurry tank 7 at the bottom of the absorption tower respectively.

Embodiment 3

[0028] Flue gas from the boiler at a temperature of 130°C with a flow rate of 8.0×10 5 Standard cubic meters per hour, the concentration of sulfur dioxide in the flue gas is 2800mg / Nm 3 , the dust content is 100mg / Nm 3 . The flue gas enters the absorption tower 6 from the flue gas inlet 1 of the absorption tower, and the flue gas rises in the absorption tower 6 and contacts the slurry sprayed by the spray layer 2 in countercurrent, mass transfer absorption and heat transfer occur, and the high-temperature flue gas evaporates into the slurry At the same time, the flue gas is rapidly saturated and cooled to 50-55°C, 60%-70% of the sulfur dioxide in the flue gas is absorbed, and 75%-80% of the dust is washed down by the sprayed slurry. The flue gas after cooling and dust removal continues to rise through the spray layer and enters the packing layer 3. The flue gas fully contacts with the absorbing liquid on the packing surface. The concentration is 30%-40%, the dust-free unsat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com