Patents

Literature

54 results about "In line filtration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

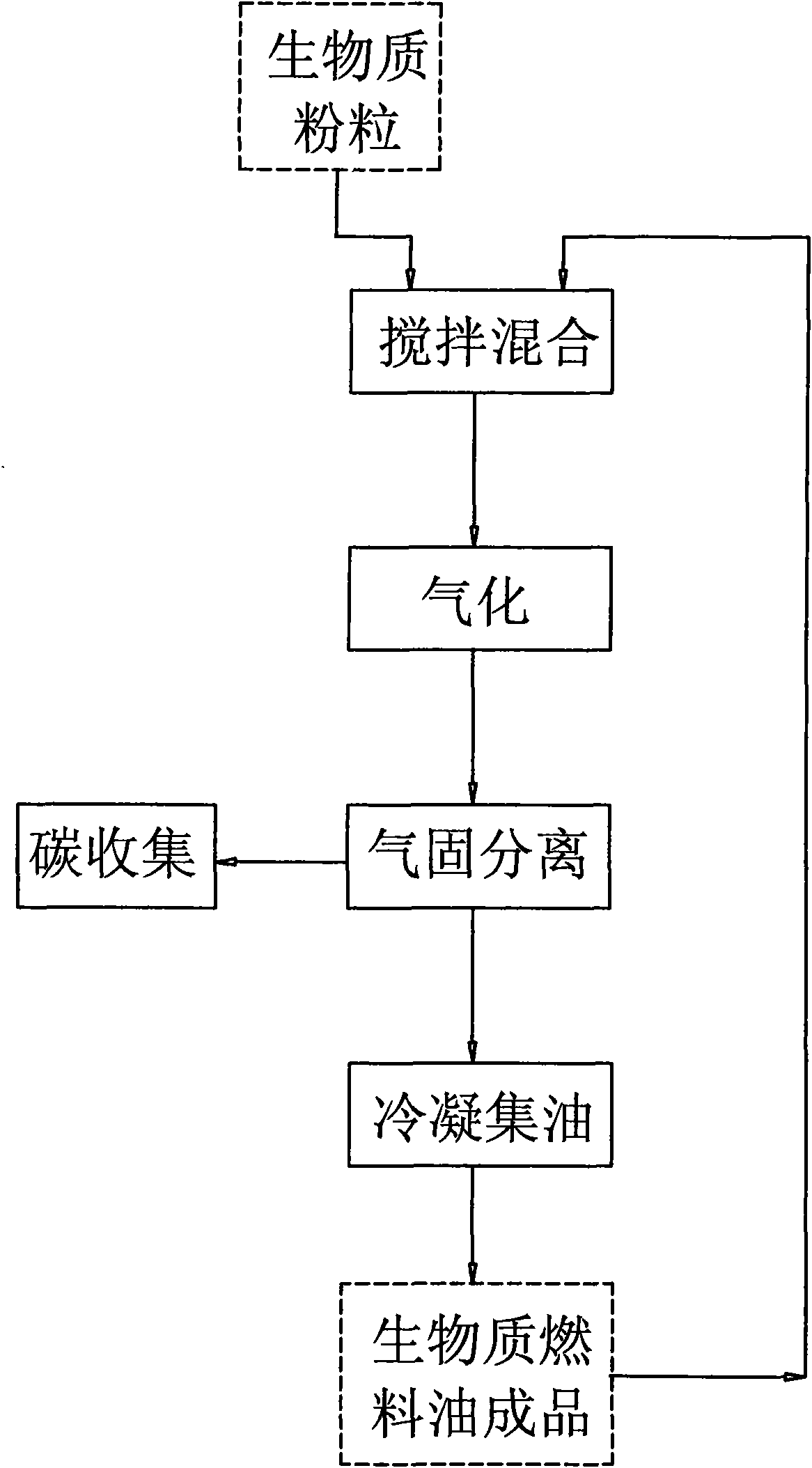

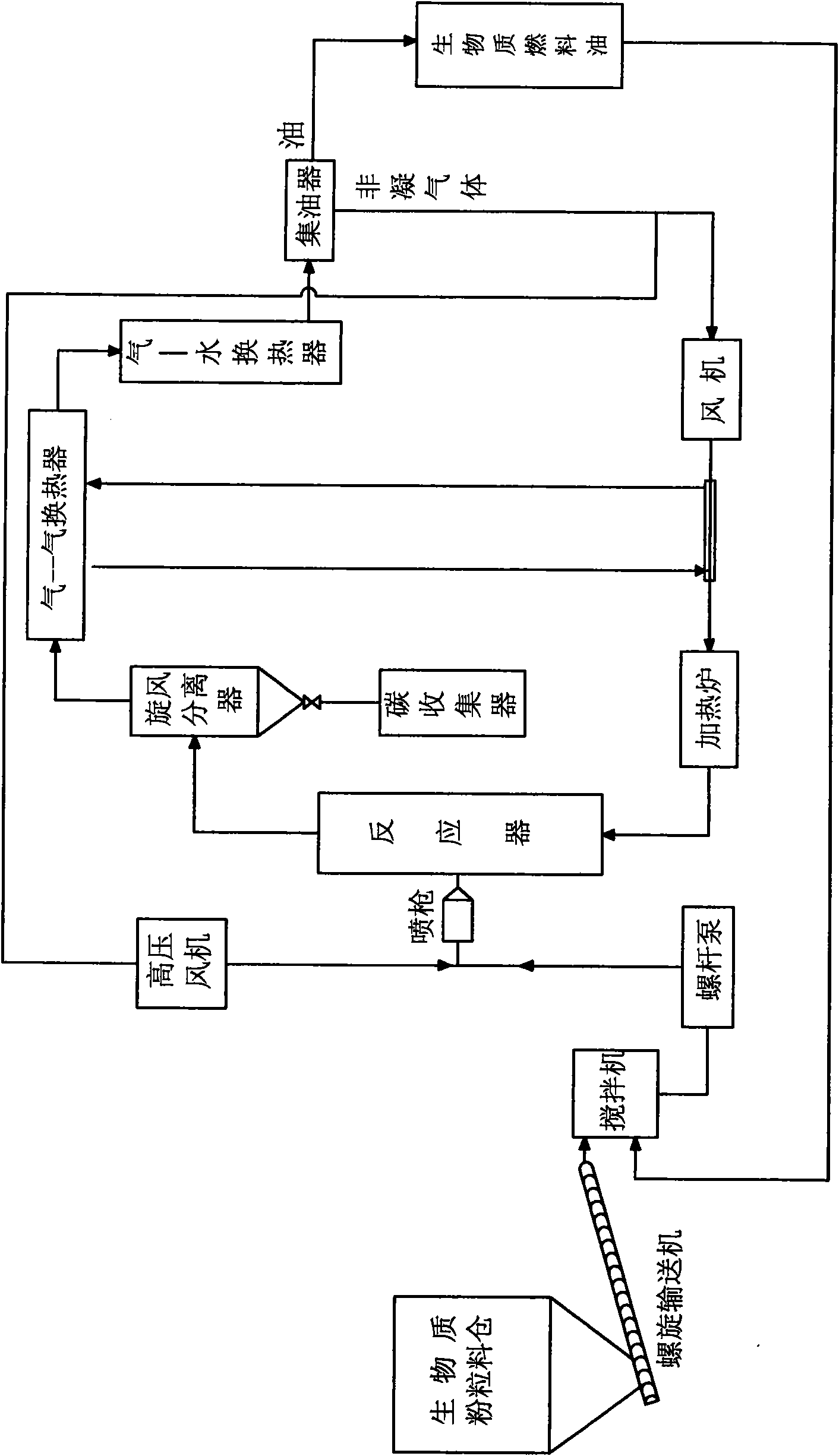

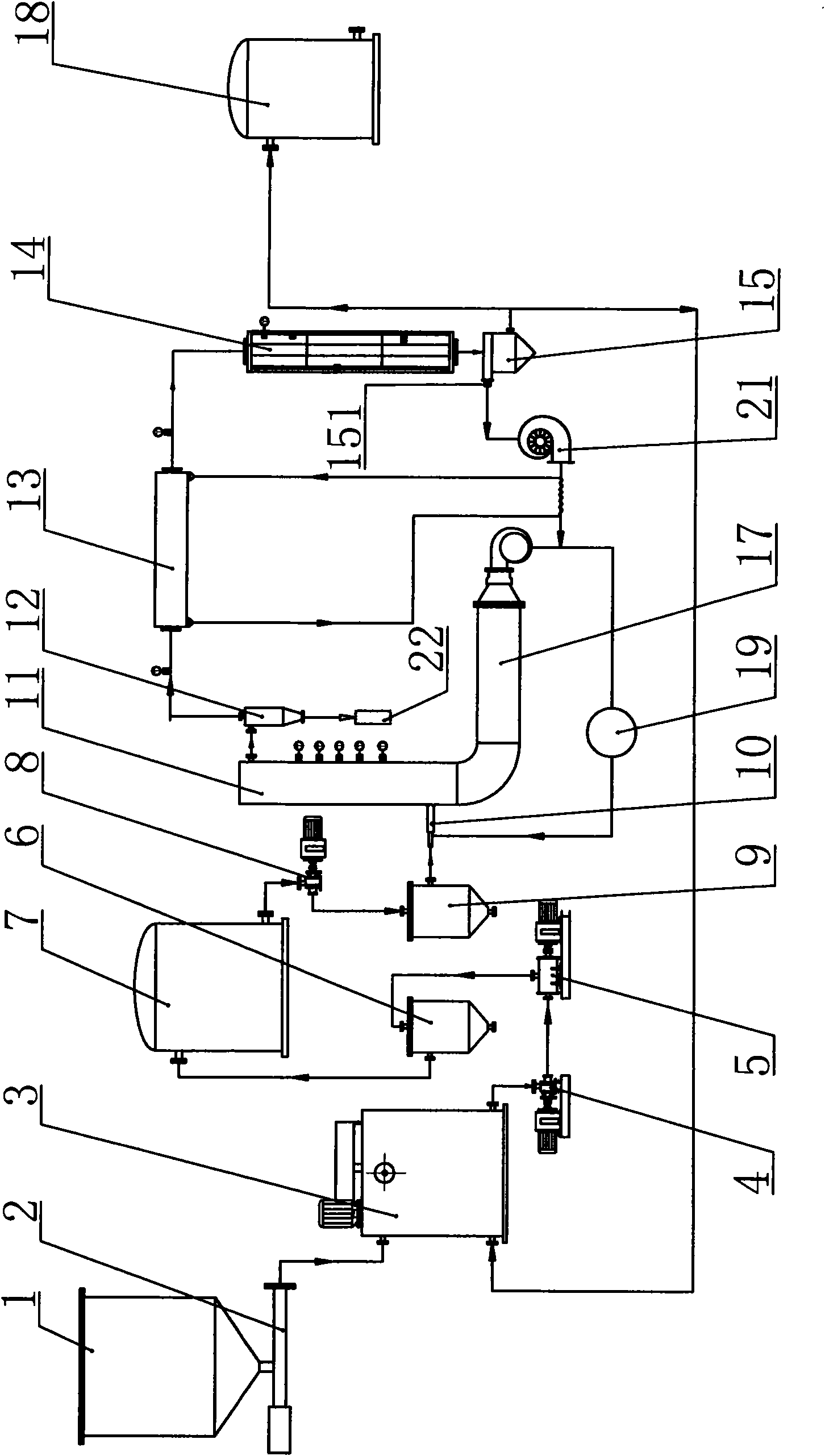

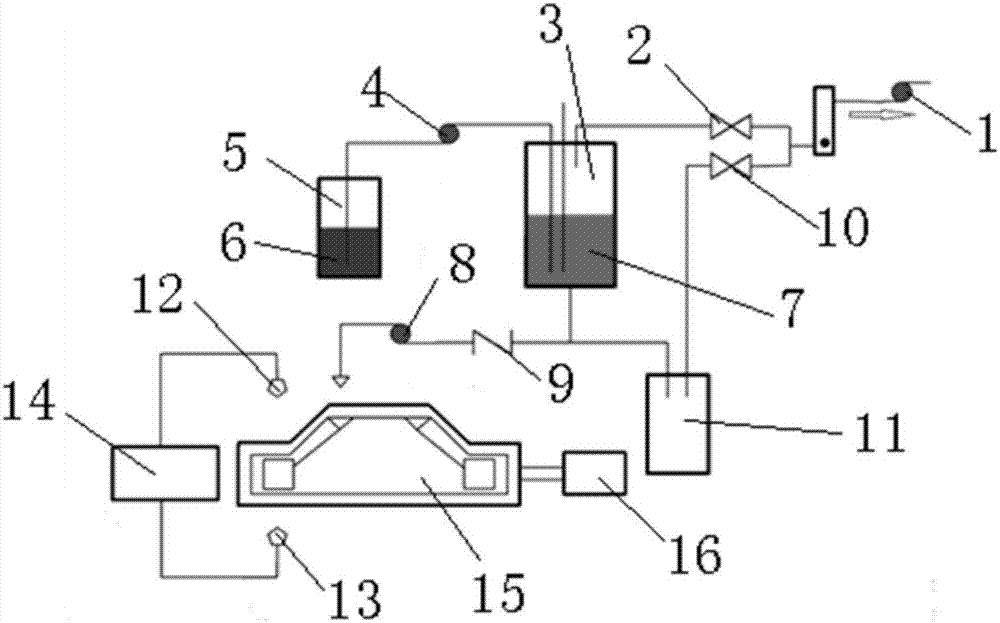

Biomass slurry atomization thermal cracking process and device

InactiveCN101550347AImprove atomization effectWell mixedLiquid hydrocarbon mixture productionProcess engineeringSlurry

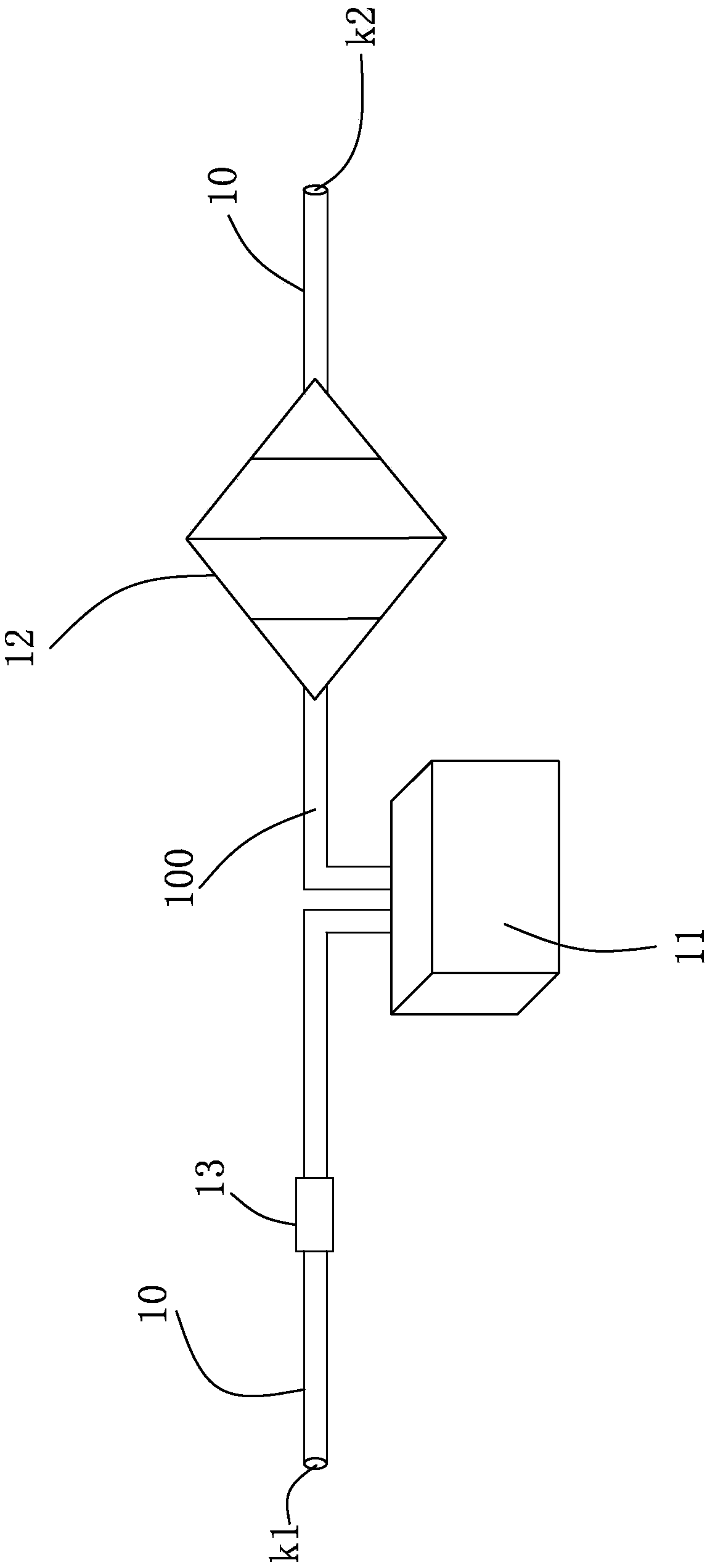

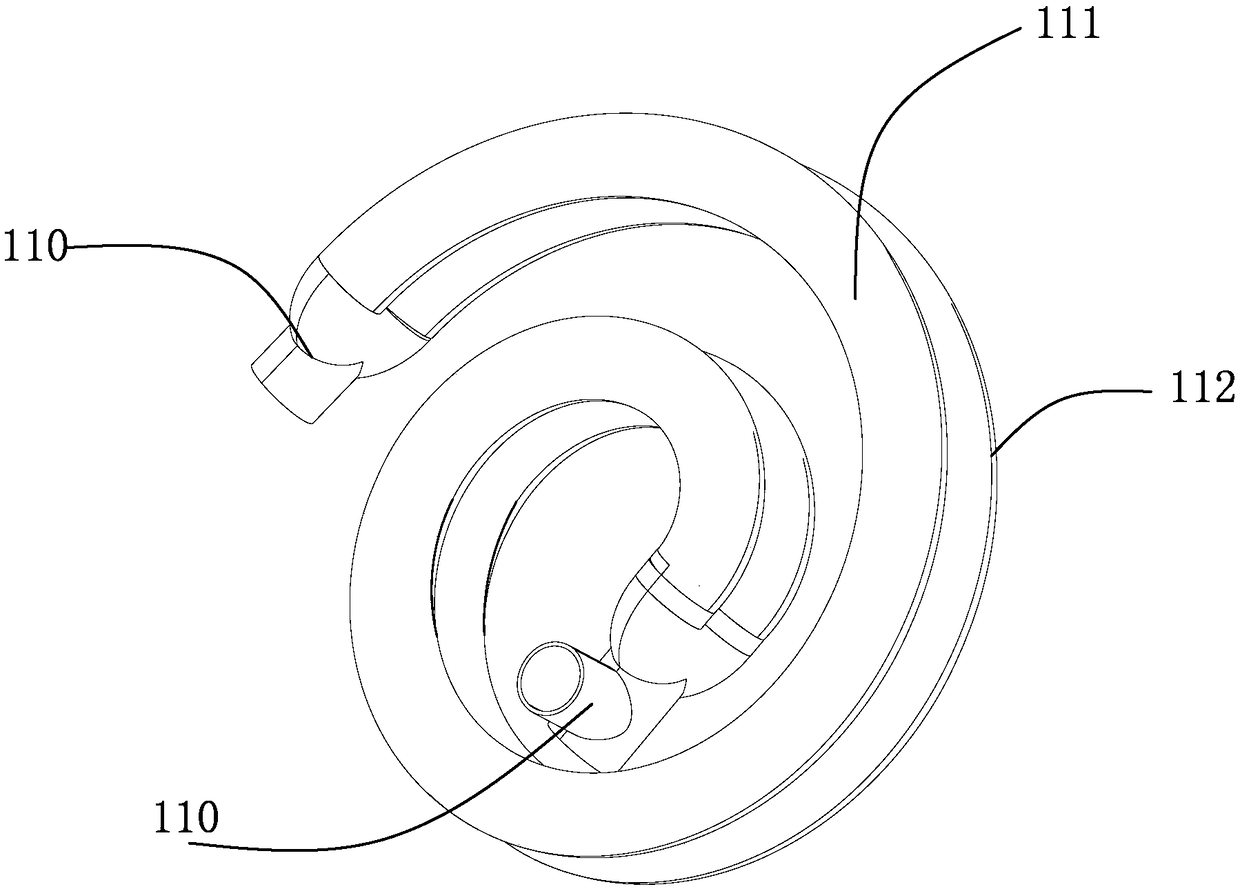

The invention relates to a biomass slurry atomization thermal cracking process which comprises the following steps of stirring, mixing, gasifying, gas-solid separating, condensing and oil gathering. Adevice of the invention comprises a screw pump, an on-line grinder, a I-stage on-line filter, a slurry biomass storage tank, a slurry supply pump, a II-stage one-line filter, an atomization spray gun, a thermal cracking reactor, a cyclone separating device, a gas-gas thermal exchanger, a steam-water thermal exchanger and an oil gathering device which are sequentially connected with the output endof a stirring machine through pipes. Biomass comprises crop straws, other plant straws, branches and wooden meals. Because of adopting the slurry atomization reactor, the invention has the advantagesthat the slurry biomass atomization effect is good, the temperature field is stable, the slurry atomization realizes the uniform mixing of gas and material for ensuring the fully thermal cracking, the thermal cracking effect and the utilization ratio of the material are improved, the structure of the device is compact, the investment cost is low, the process adopts the continuous circulating operation, the production efficiency is high and the oil yield is large.

Owner:江苏东工环保科技股份有限公司

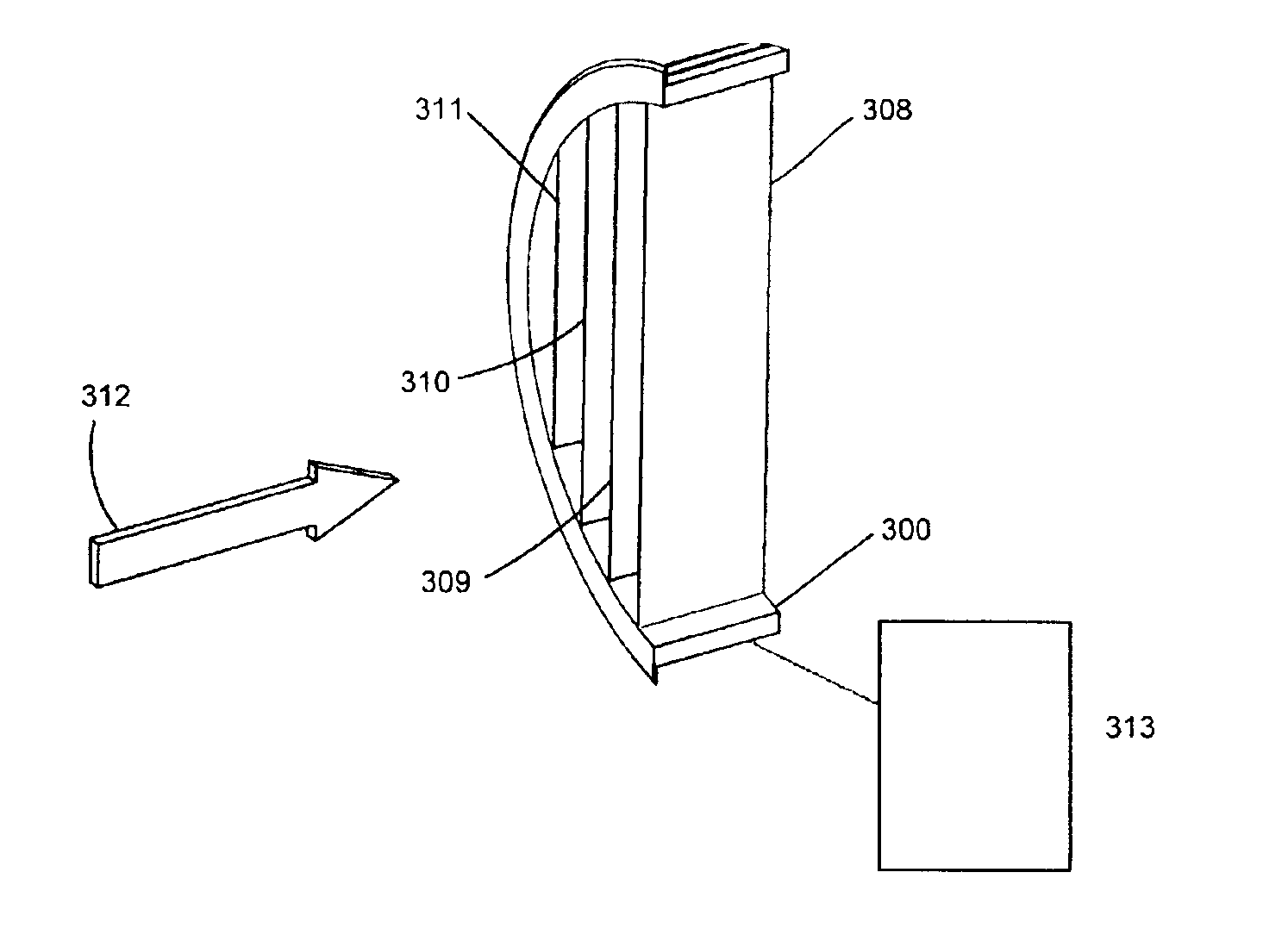

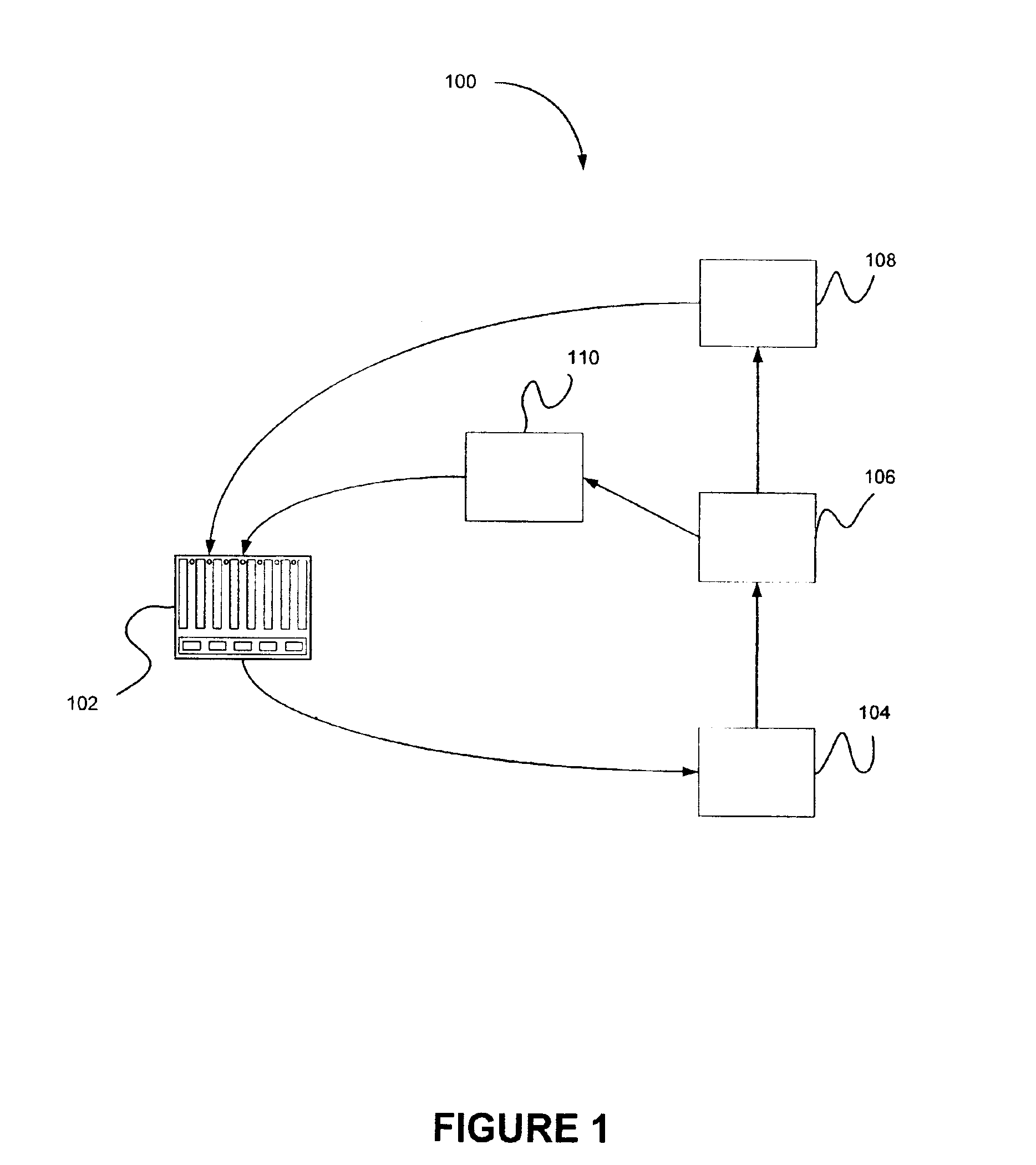

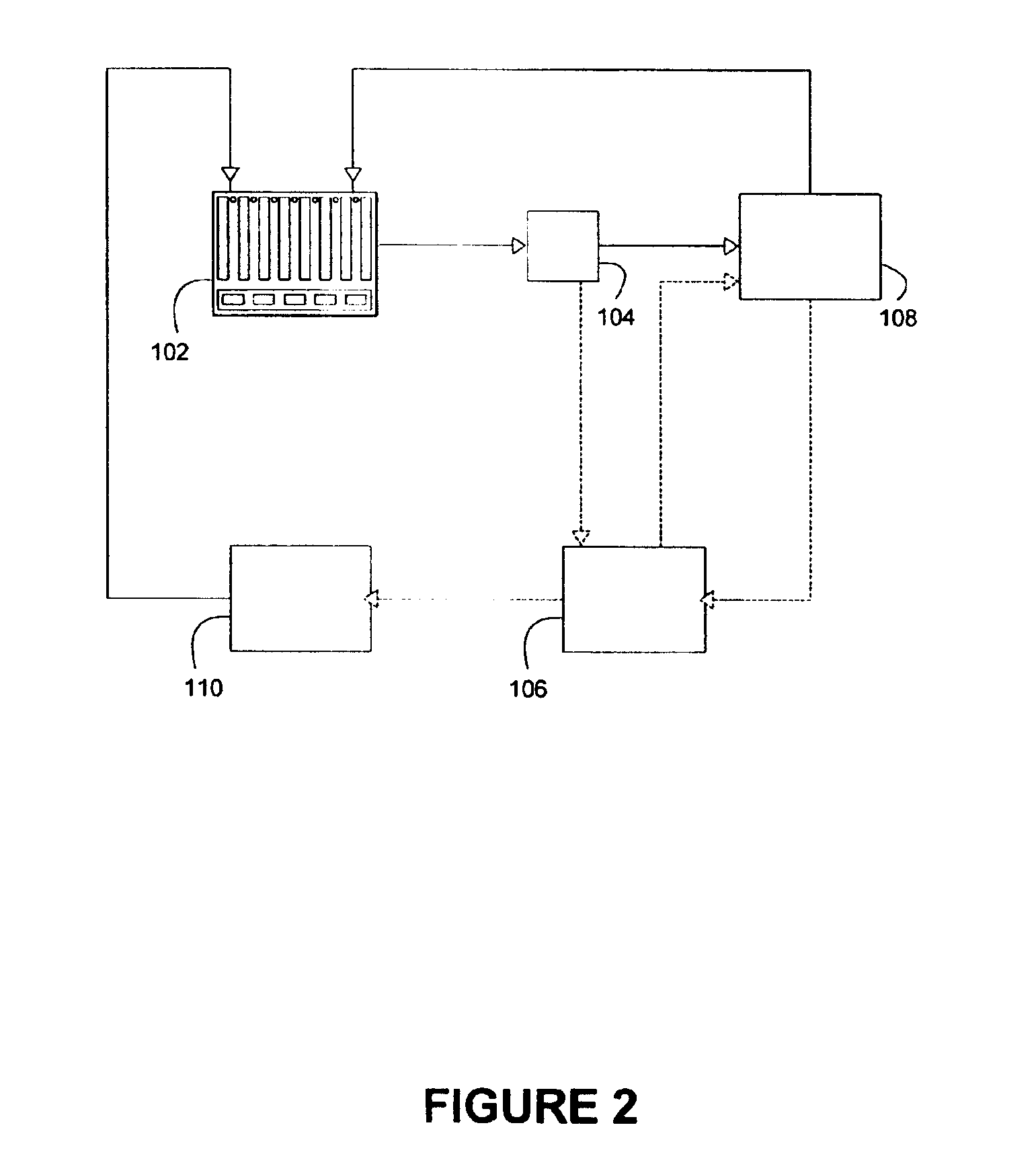

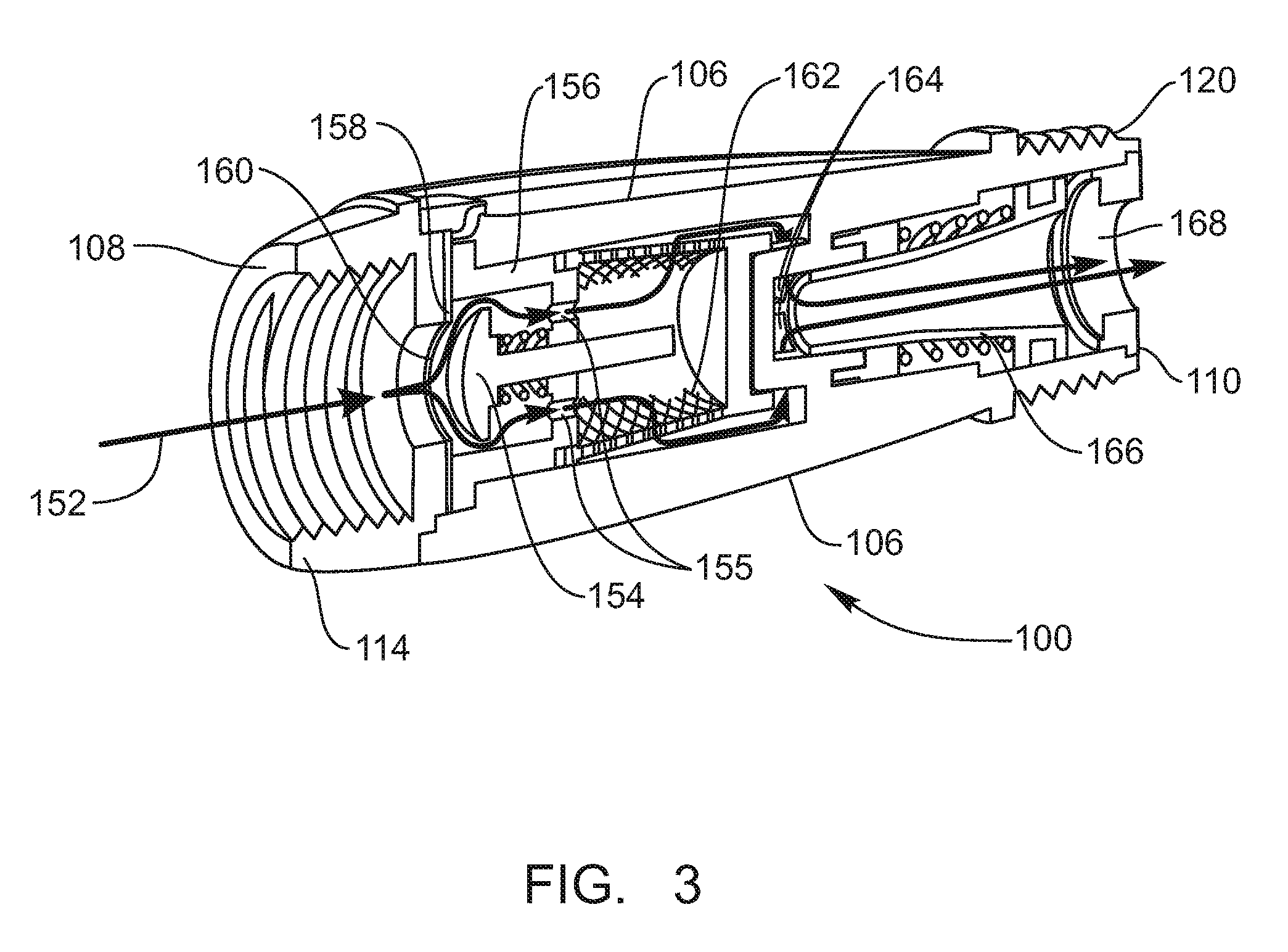

In-line filtration for a particle-based electrochemical power system

A system for filtering particles within a multiphase fluid that comprises a particulate phase is disclosed. The system comprises a first plurality of substantially parallel, substantially planar thin slabs separated by a predetermined distance to retain particles having a maximum cross-sectional dimension greater than the predetermined distance, and provides at least one flow path for at least part of the multiphase fluid. In one application, the system is used in connection with an electrochemical power source and components thereof, wherein the multiphase fluid comprises flowable fuel.

Owner:TECK COMINCO METALS LTD

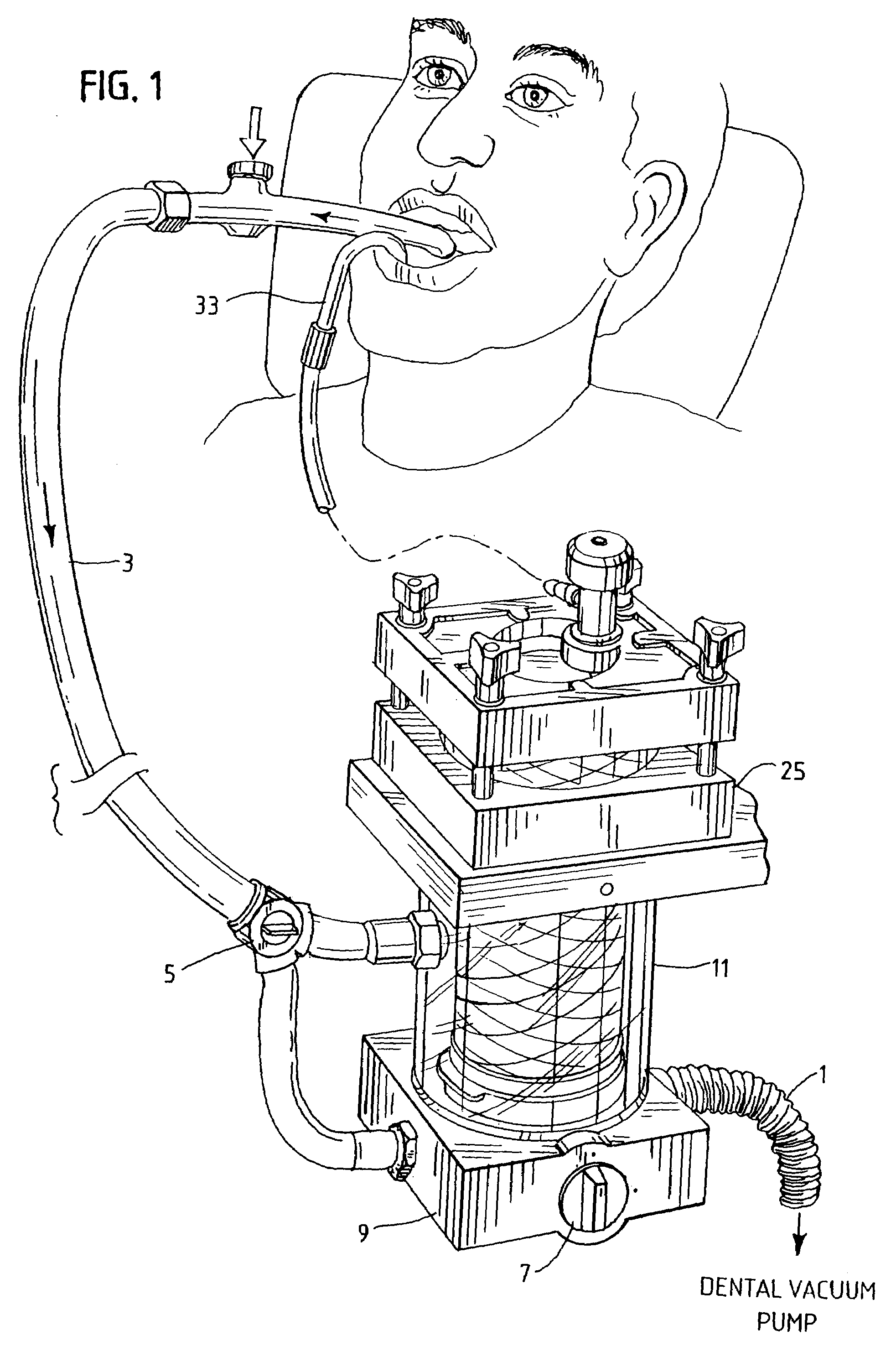

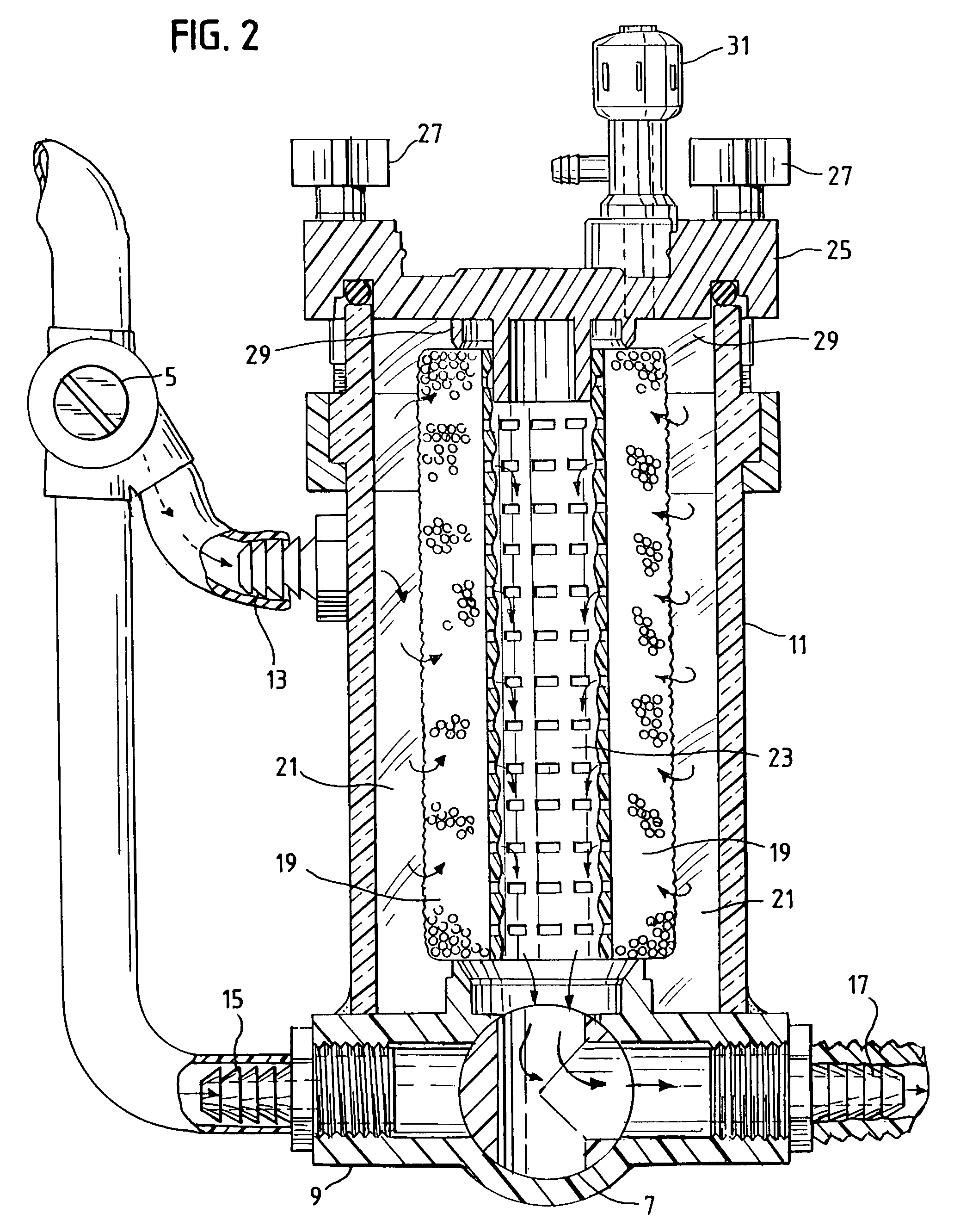

Method and apparatus for removing particulate metals from dental waste water

InactiveUS7182599B2Easy to replaceTransportation safetySettling tanks feed/dischargeIntravenous devicesWastewaterStopcock

Owner:NAVY UNITED STATES OF AMERICA AS REPRESENTED BY SEC OF THE

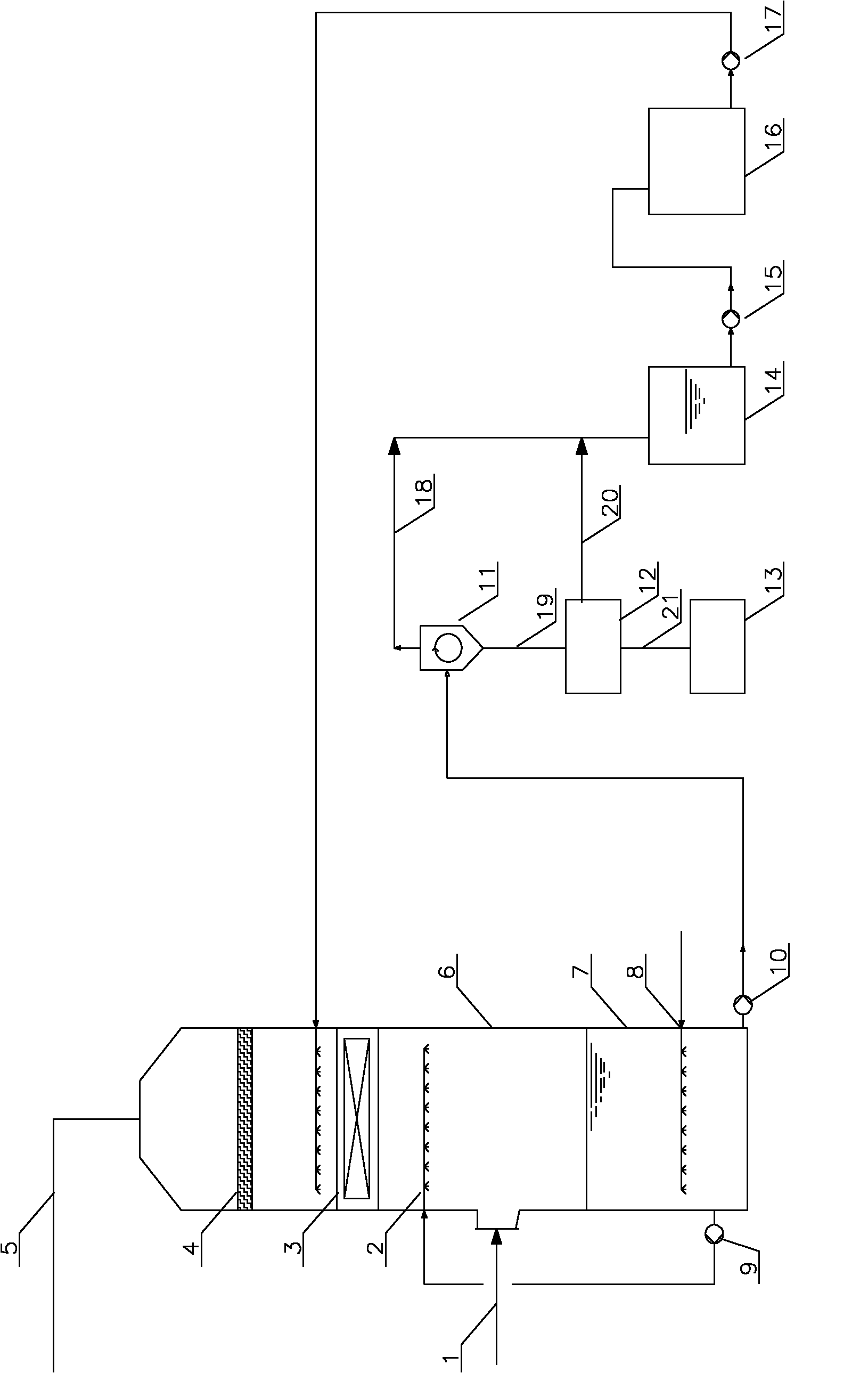

Device and method for depriving sulfur dioxide in flue gas by using ammonia water

InactiveCN101898082AQuality improvementImprove desulfurization efficiencyDispersed particle separationAmmonium sulfatesEngineeringLine filter

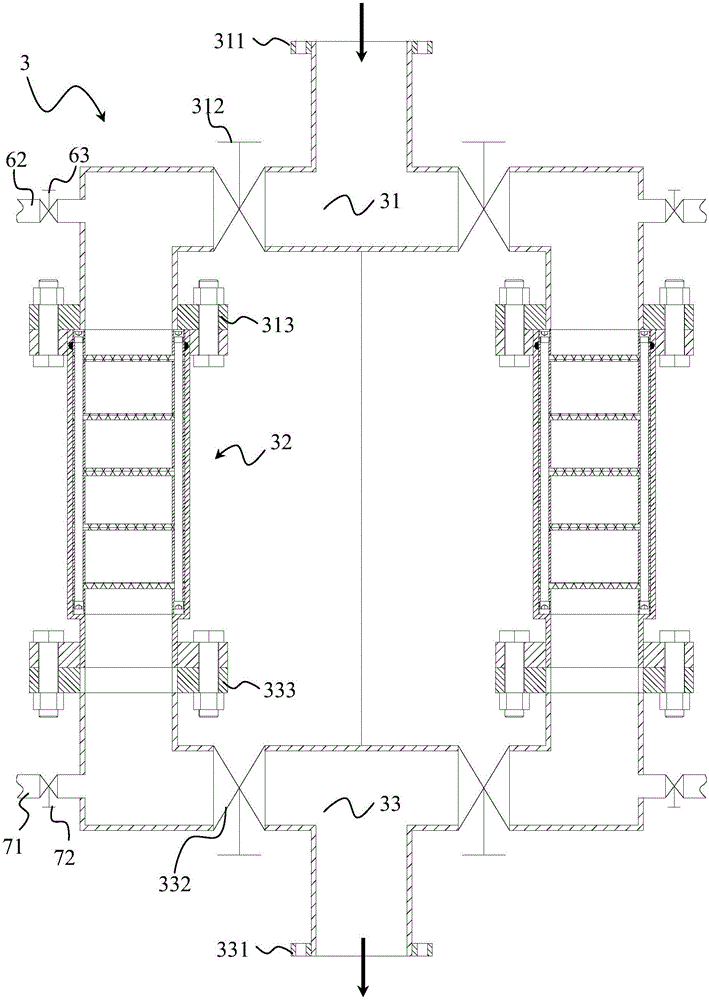

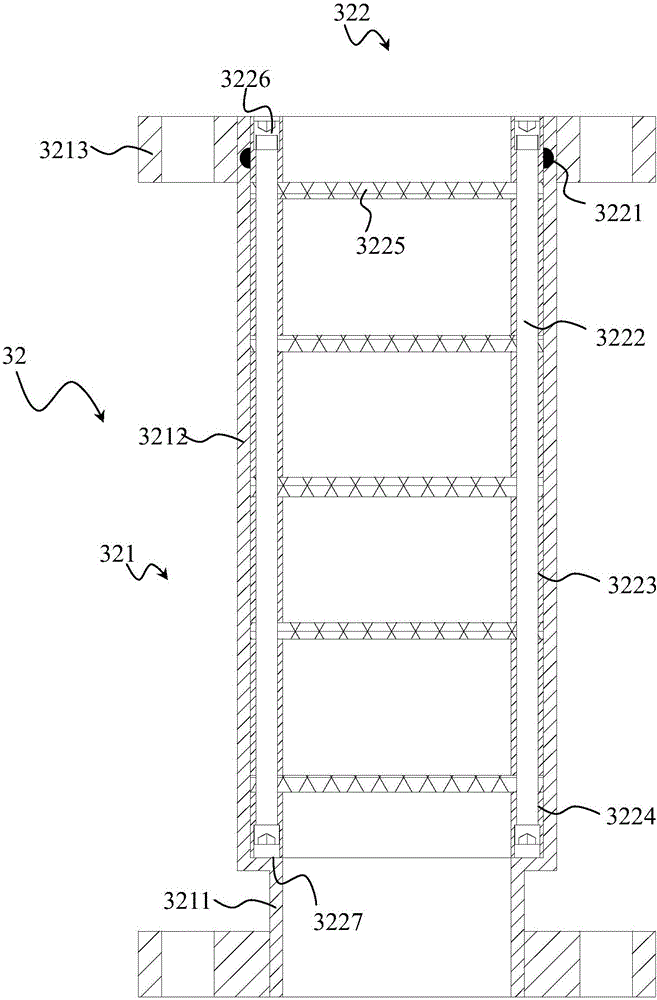

The invention relates to a device and a method for depriving sulfur dioxide in flue gas by using ammonia water. The device comprises an absorption tower, wherein the absorption tower comprises a tower bottom pulp chest, spraying layers, packing layers and defrosters from bottom to top; the middle part of the absorption tower is arranged below the spraying layer, a flue gas inlet is arranged above the of the tower bottom pulp chest, and the top of the absorption tower is provided with a flue gas outlet; the tower bottom pulp chest of the absorption tower is internally provided with an aeration pipe; the absorption tower is externally provided with circulating pumps, the number of the circulating pumps accords with the number of layers for the spraying layers, an outlet of each circulating pump is respectively connected with spray throwers in the spraying layer in one layer, the defrosters are arranged in the upper part of the absorption tower and an inlet of each circulating is connected with the tower bottom pulp chest of the absorption tower; and the tower is externally provided with an in-line filter, and filtered unsaturated ammonium sulfate solution is taken as absorption liquids of the packing layers to thoroughly eliminate the possibility of filler scaling block. The method of the invention has the advantages of high deprivation efficiency, low liquid-air ratio, difficult scaling block, low content of ammonium sulfate particles and liquid drops contained in the flue gas from the outlets, good quality of secondary products and the like.

Owner:武汉兴能环保技术有限公司

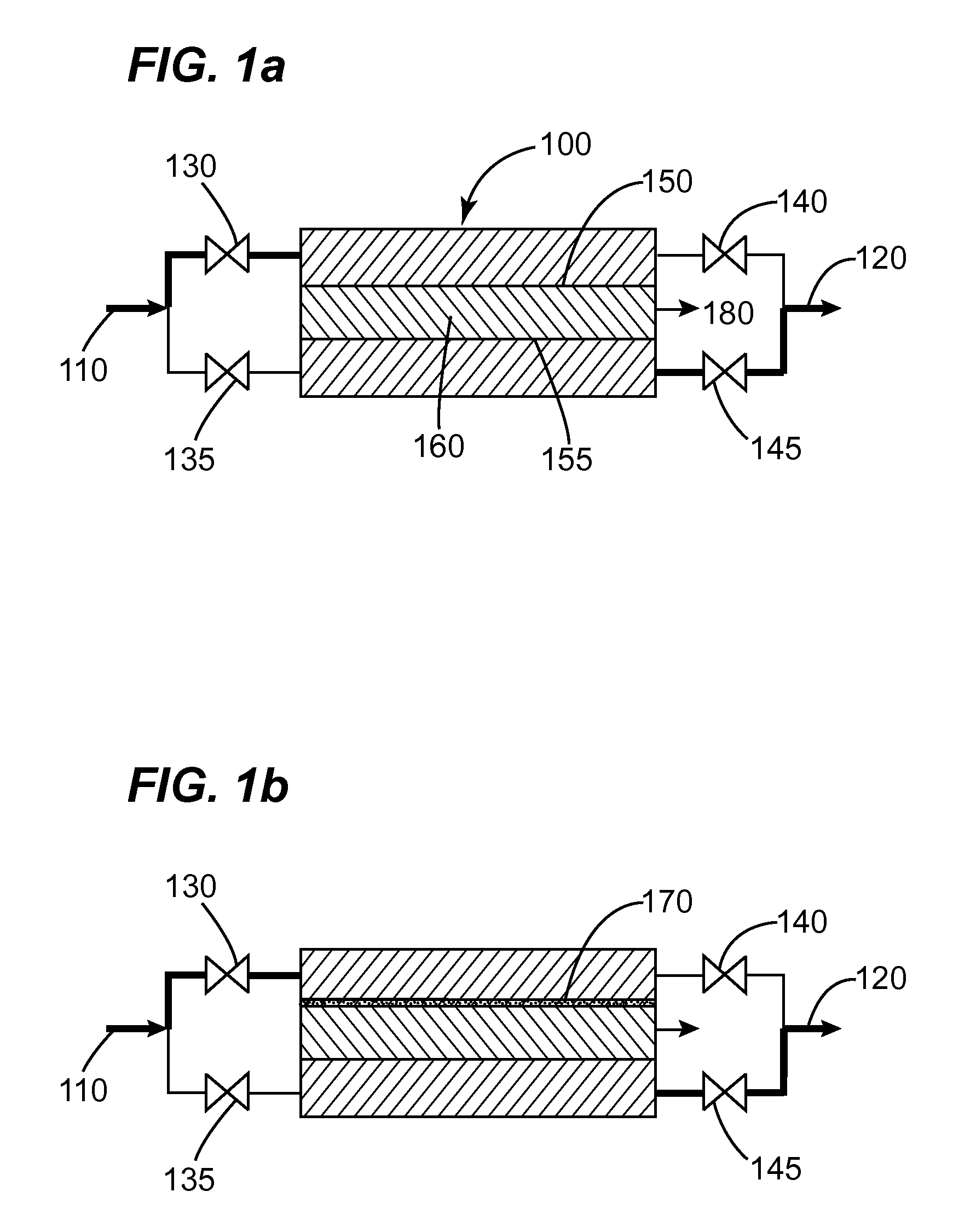

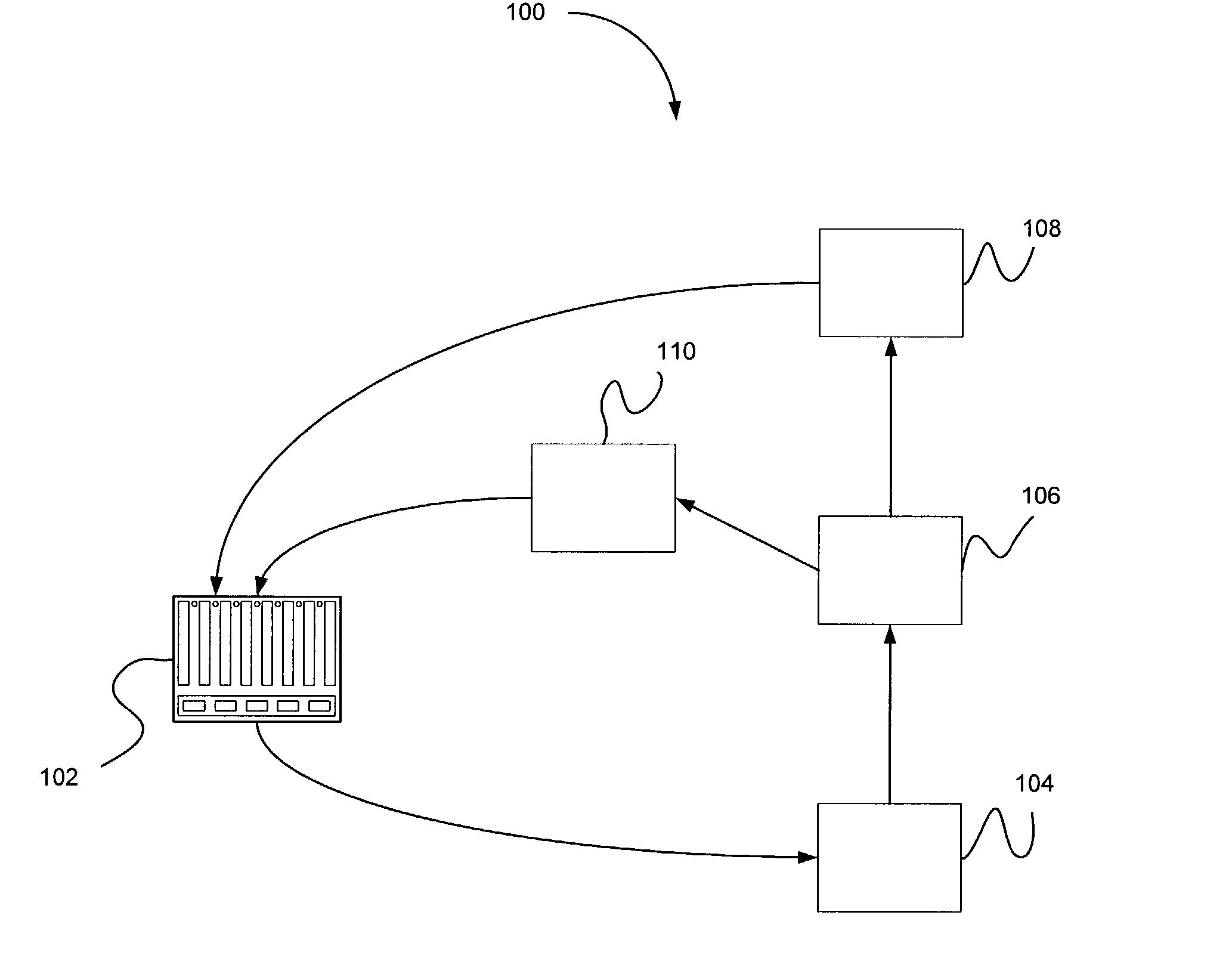

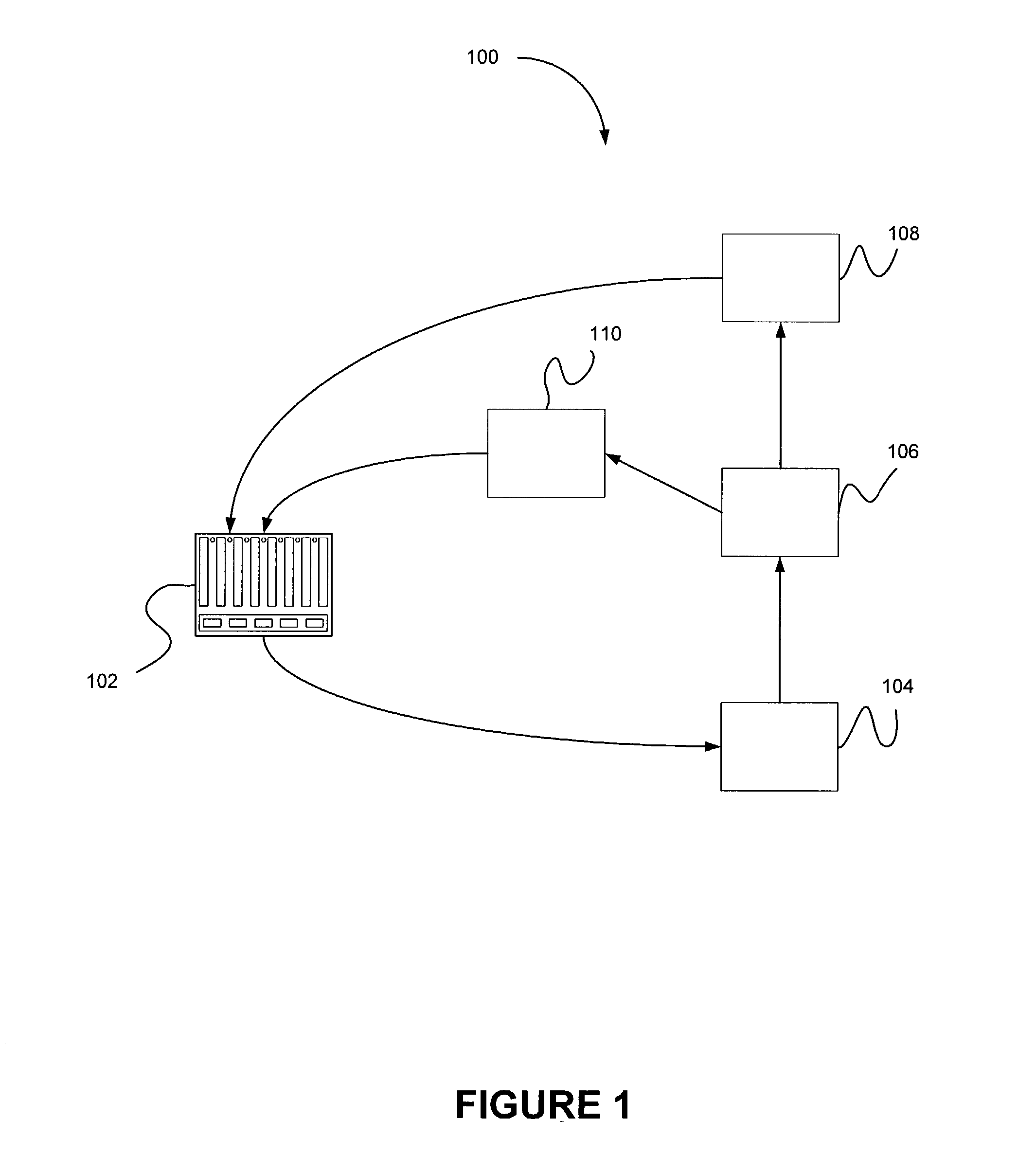

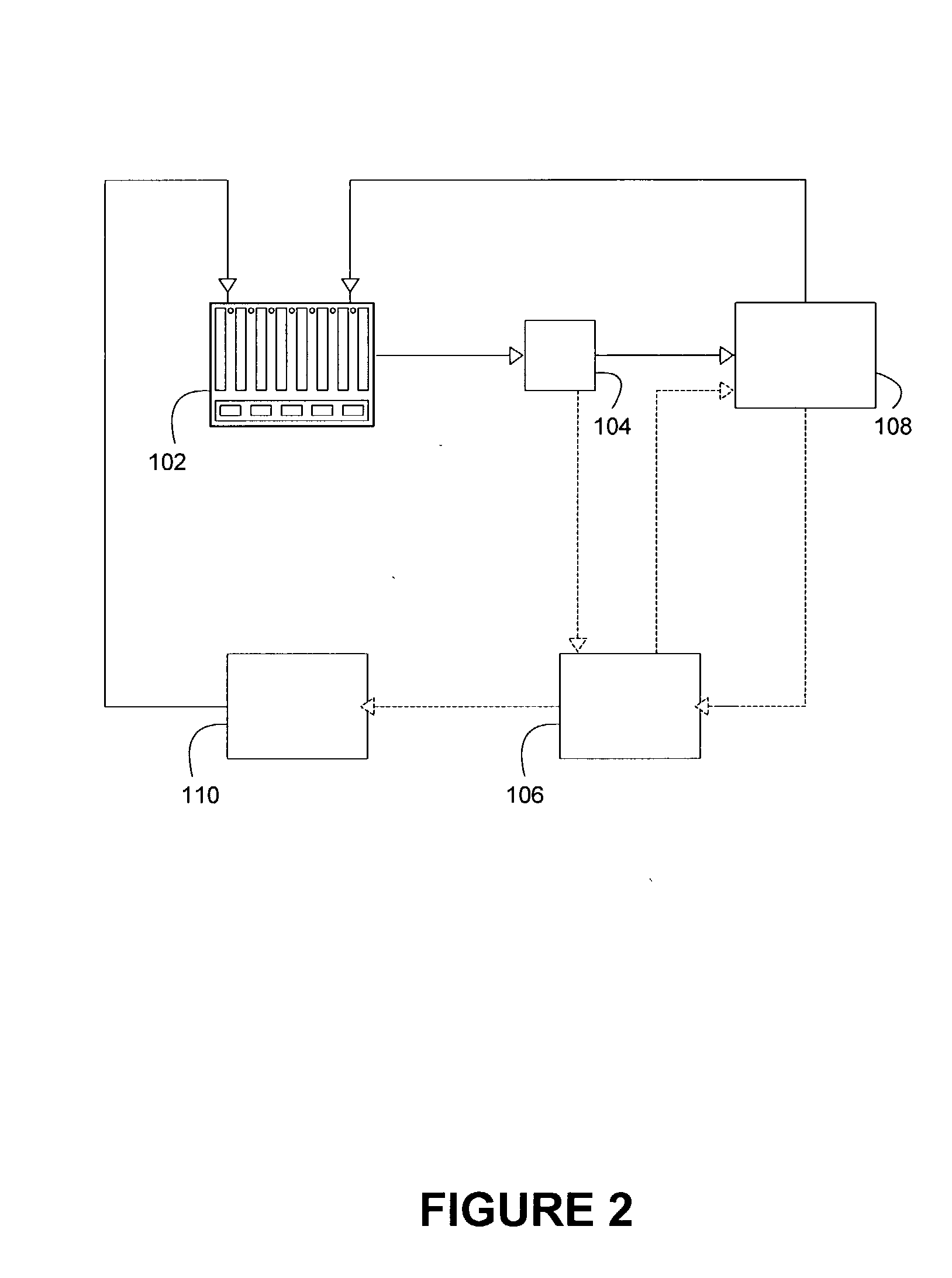

In-line filtration systems

InactiveUS20090057210A1Inhibition formationIncrease effective operation timeMembranesSpecific water treatment objectivesCounter flowIndustrial systems

A filtration system is disclosed that uses a combination of dead end filtration across opposing membranes with a sample take-off in the middle and cross-flow to prevent cake formation on these opposing filters. In one embodiment is a system that uses opposing filters with a central collection chamber that flips flow back and forth between the sides at a frequency that minimizes filter cake formation. In another embodiment, a combination flip-flip, cross flow system is disclosed. An additional embodiment discloses an actuator valve driven sampling system, in which valves collect the cross flow / counter flow filter cake samples as they are liberated from a filter surface and a quick through filter fluid pulse loosens the sample cake from the filter material. The invention increases effective operation time, allows for continuous filtration operation without interruption, and provides filtered samples that accurately represent the concentration of macromolecular species in industrial systems.

Owner:GENERAL ELECTRIC CO

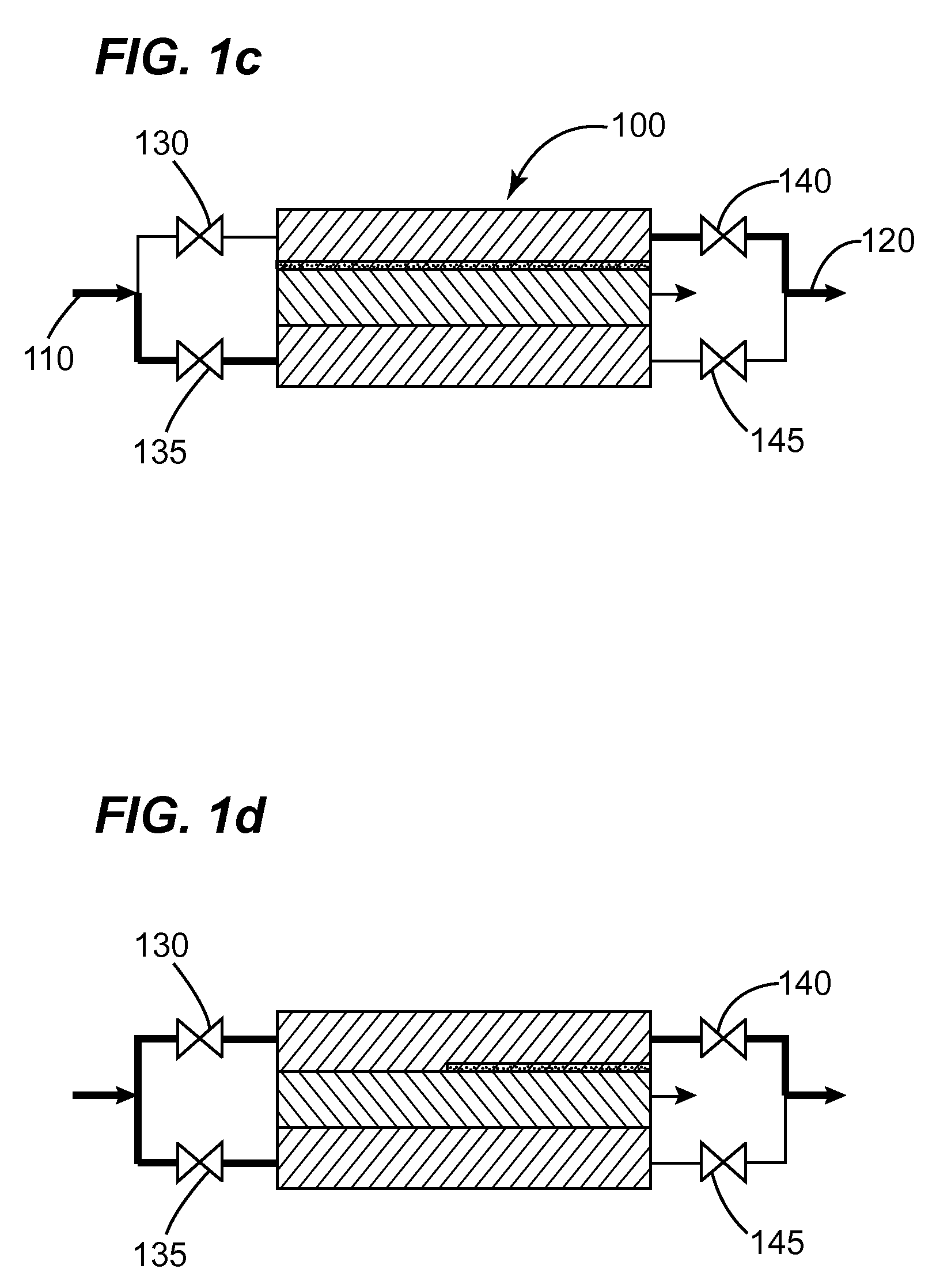

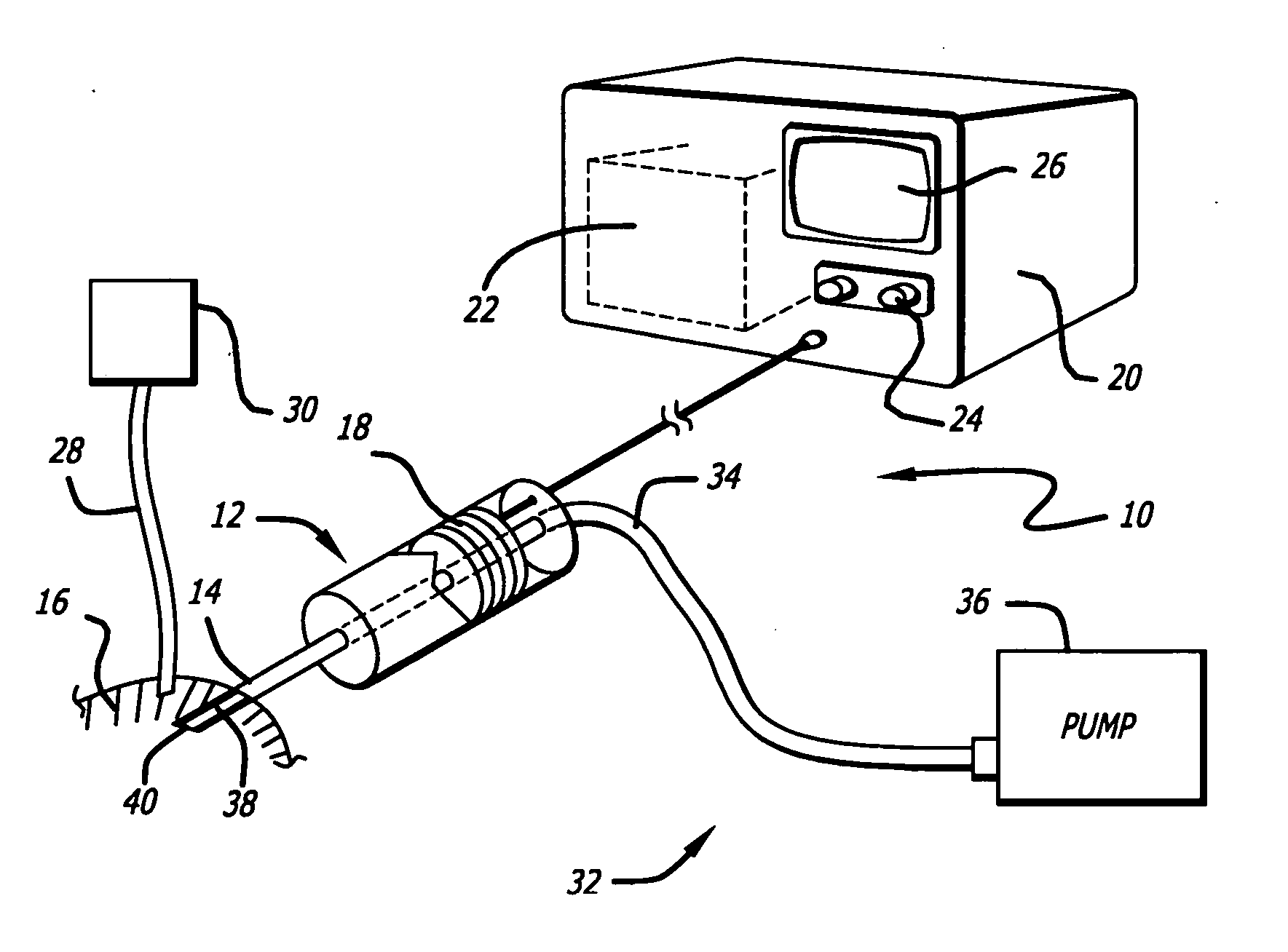

Aspiration system for medical devices

An aspiration tube that has a relatively high fluidic resistance. The tube is coupled to a medical device and a pump of an aspiration system. The tube can be designed to create a pressure drop that at least equals the maximum vacuum pressure of the pump. The fluidic resistance can be accomplished with a tube having an inner diameter less than 0.06 inches. The aspiration tube and an irrigation tube may be coupled to an anterior chamber of a cornea during a phaco procedure. The high resistance of the aspiration tube minimizes the instantaneous change of flowrate out of the cornea in the event an occlusion is cleared from the tube. The aspiration tube is sized so that even if a maximum pressure occurs, the resultant aspiration flowrate will be such that the cornea will not be damaged when an occlusion is cleared from the tube. An in-line filter may also be attached to the aspiration tube to filter out particles in the system.

Owner:DATA

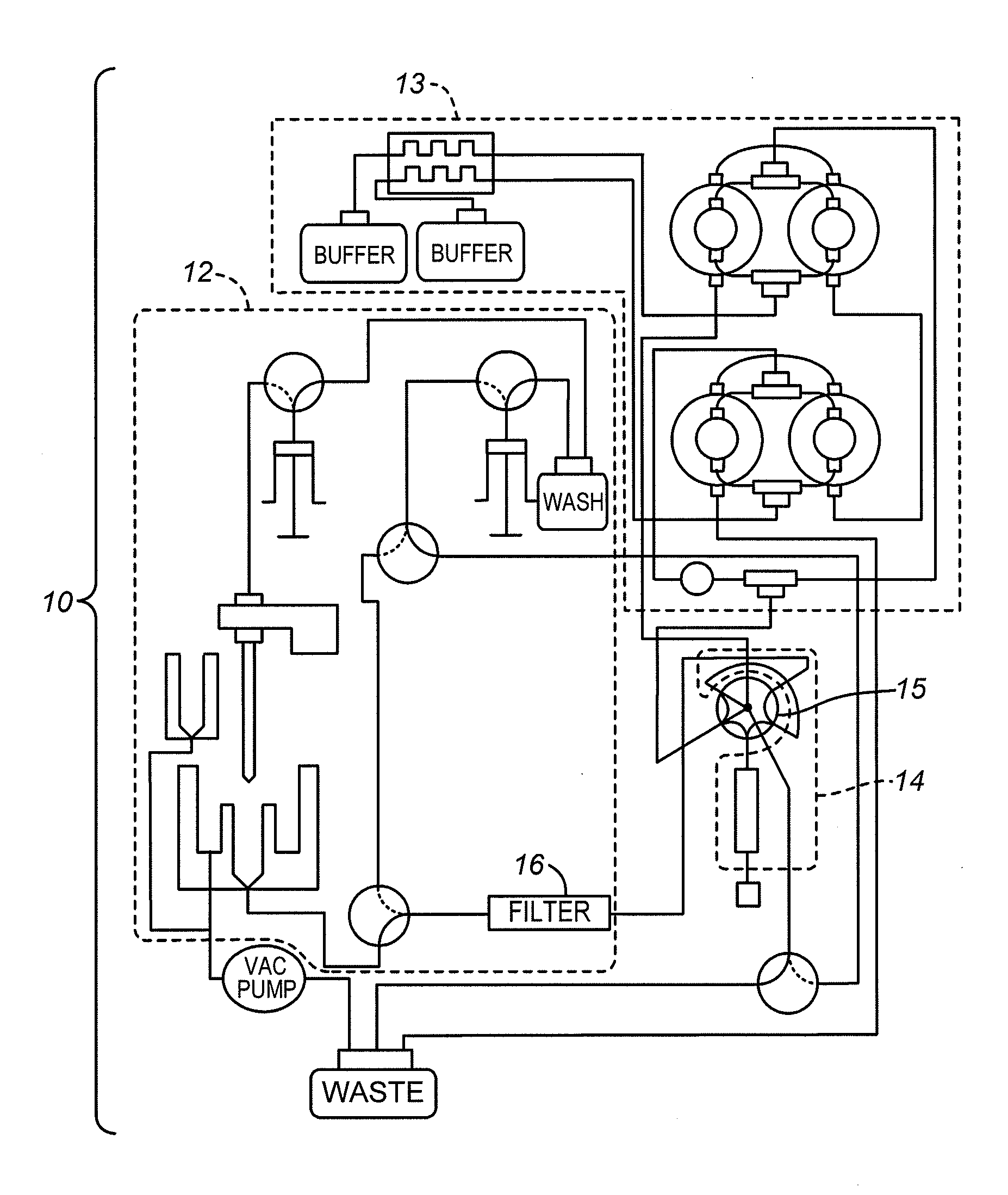

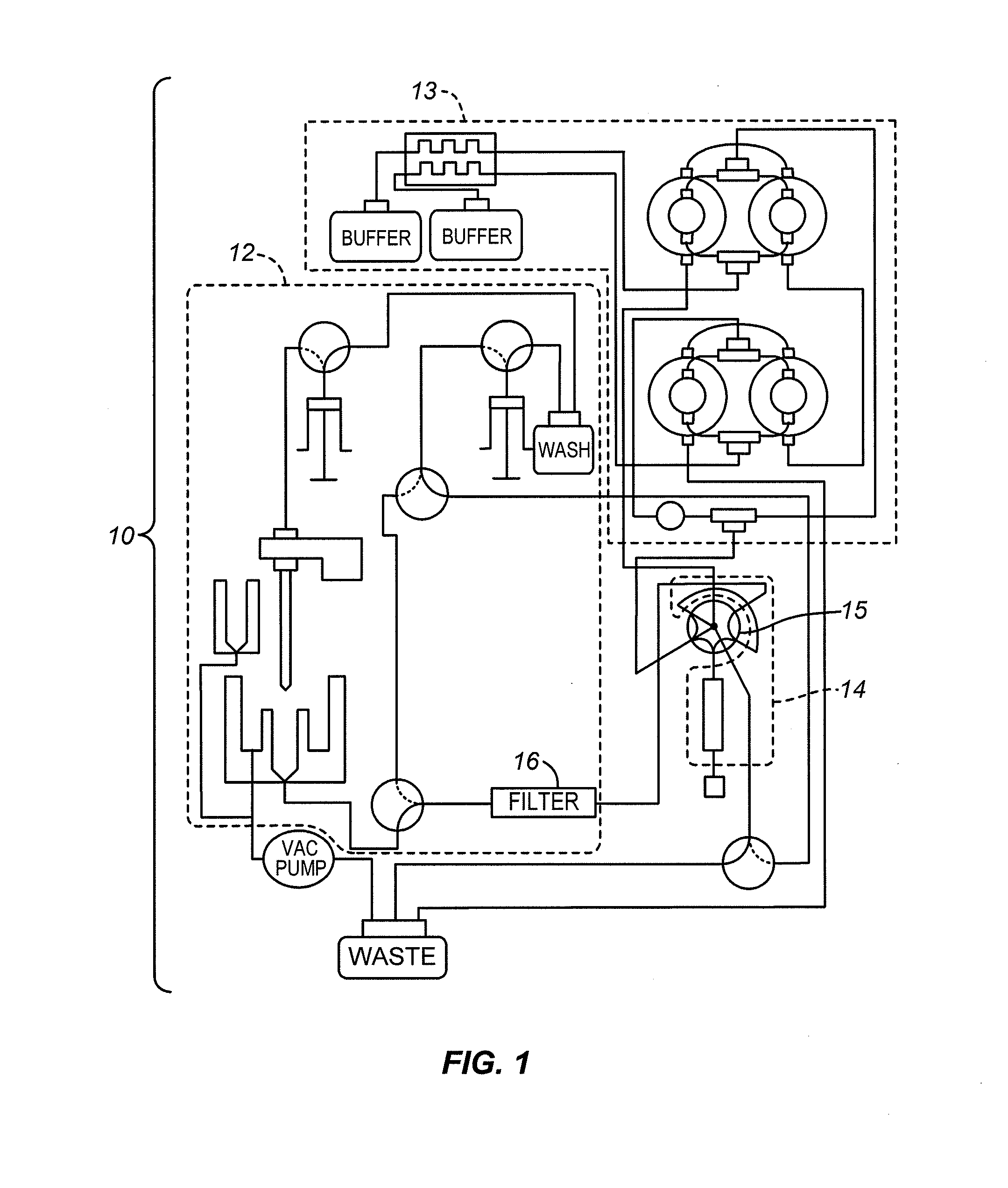

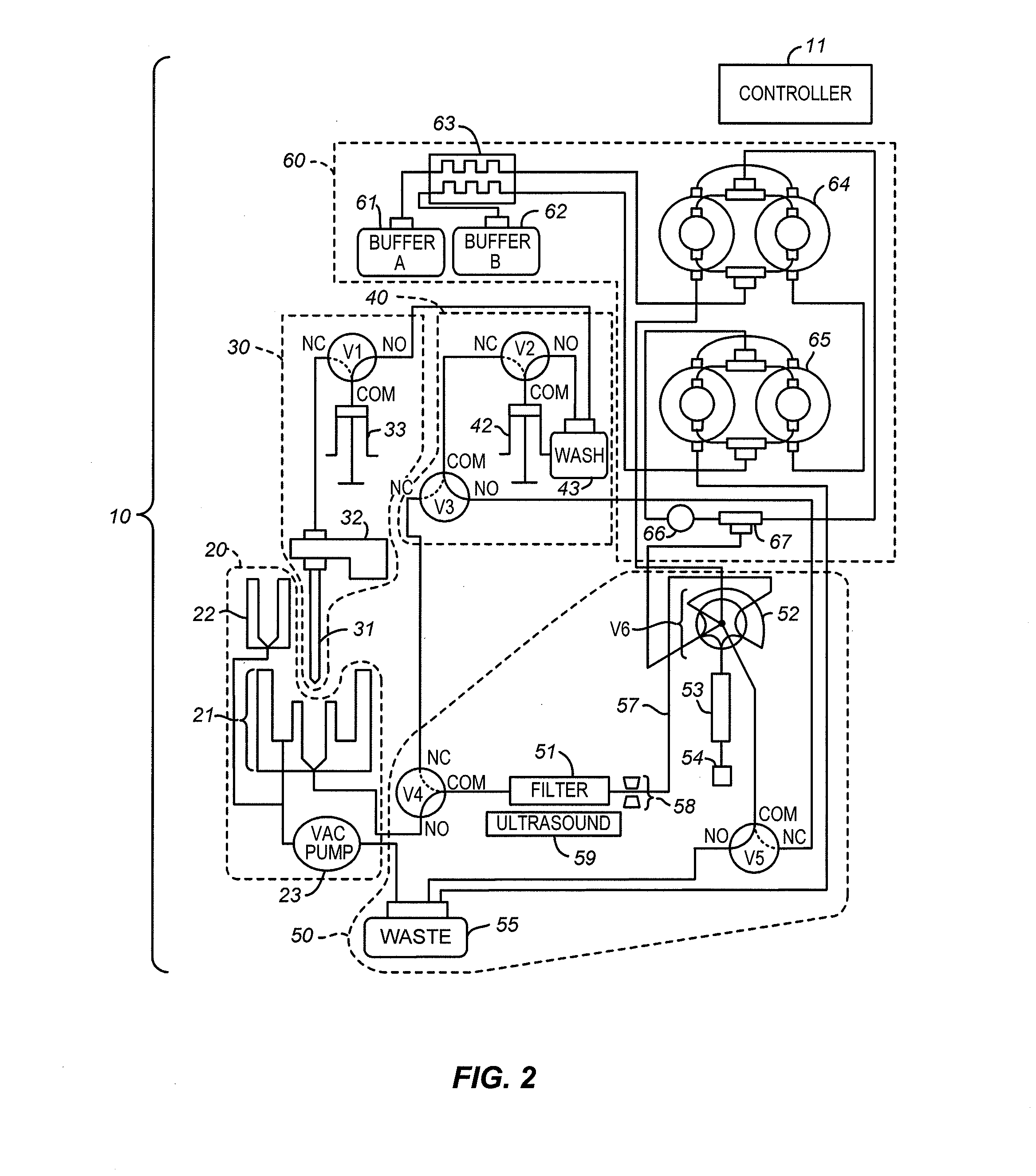

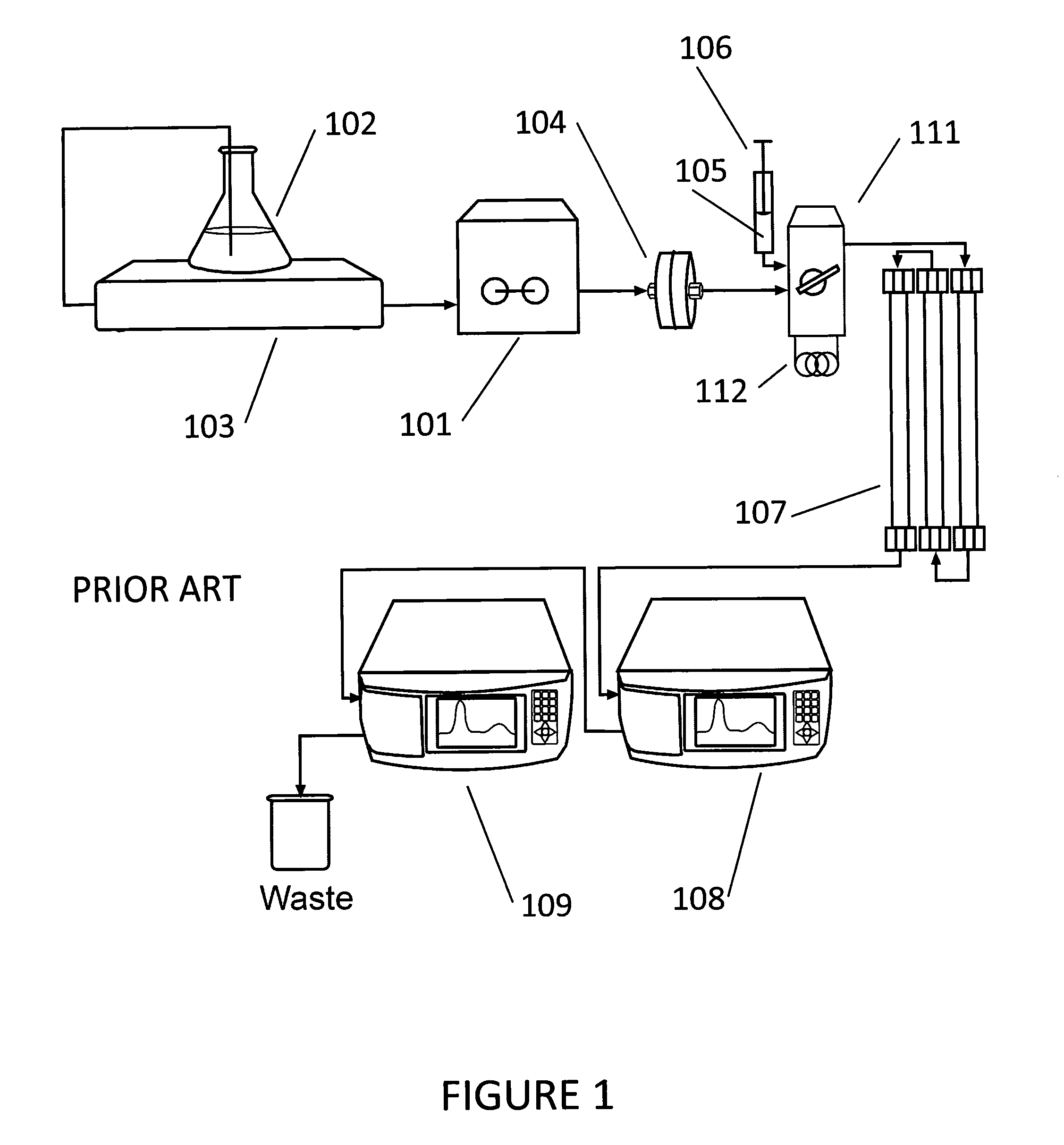

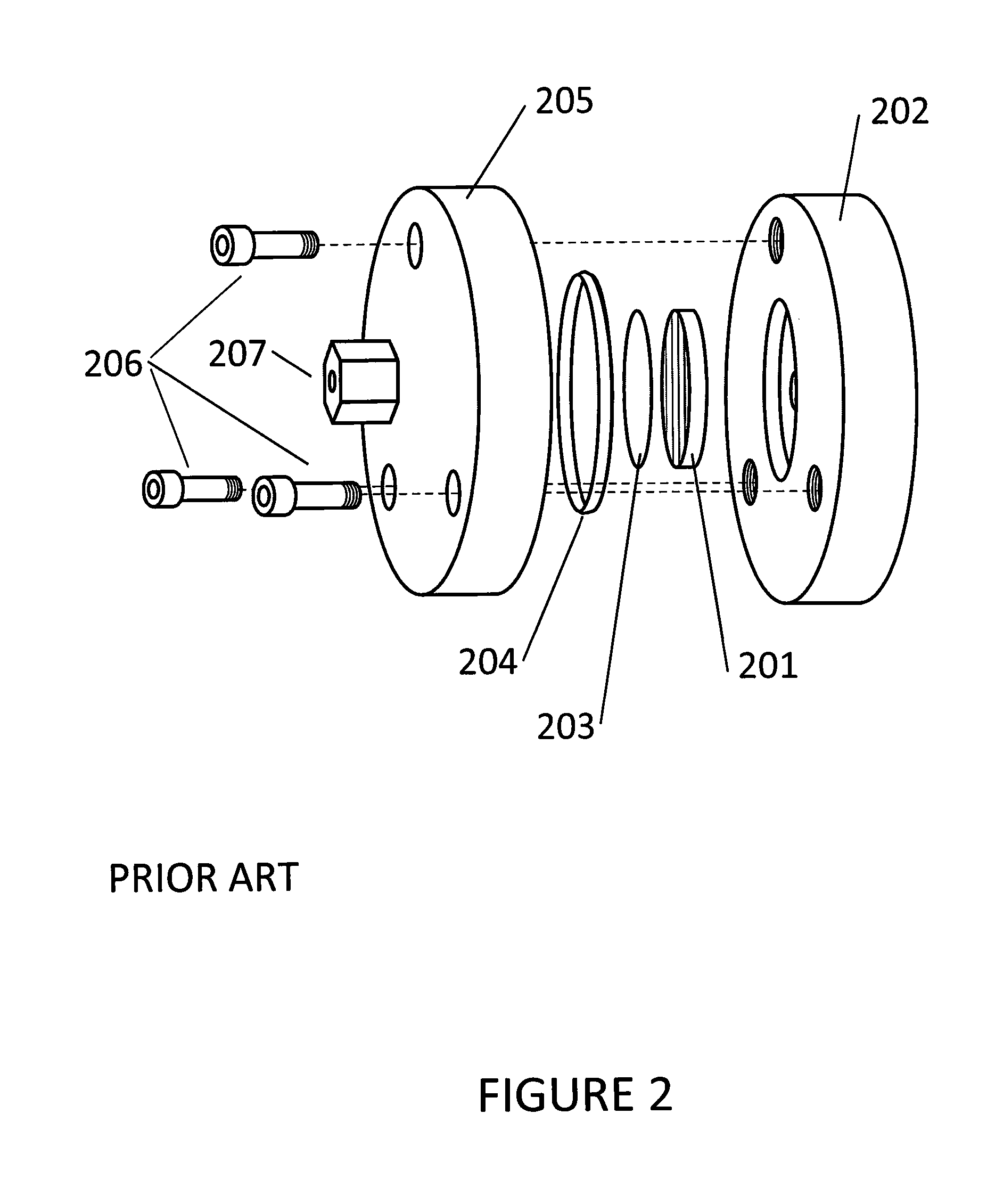

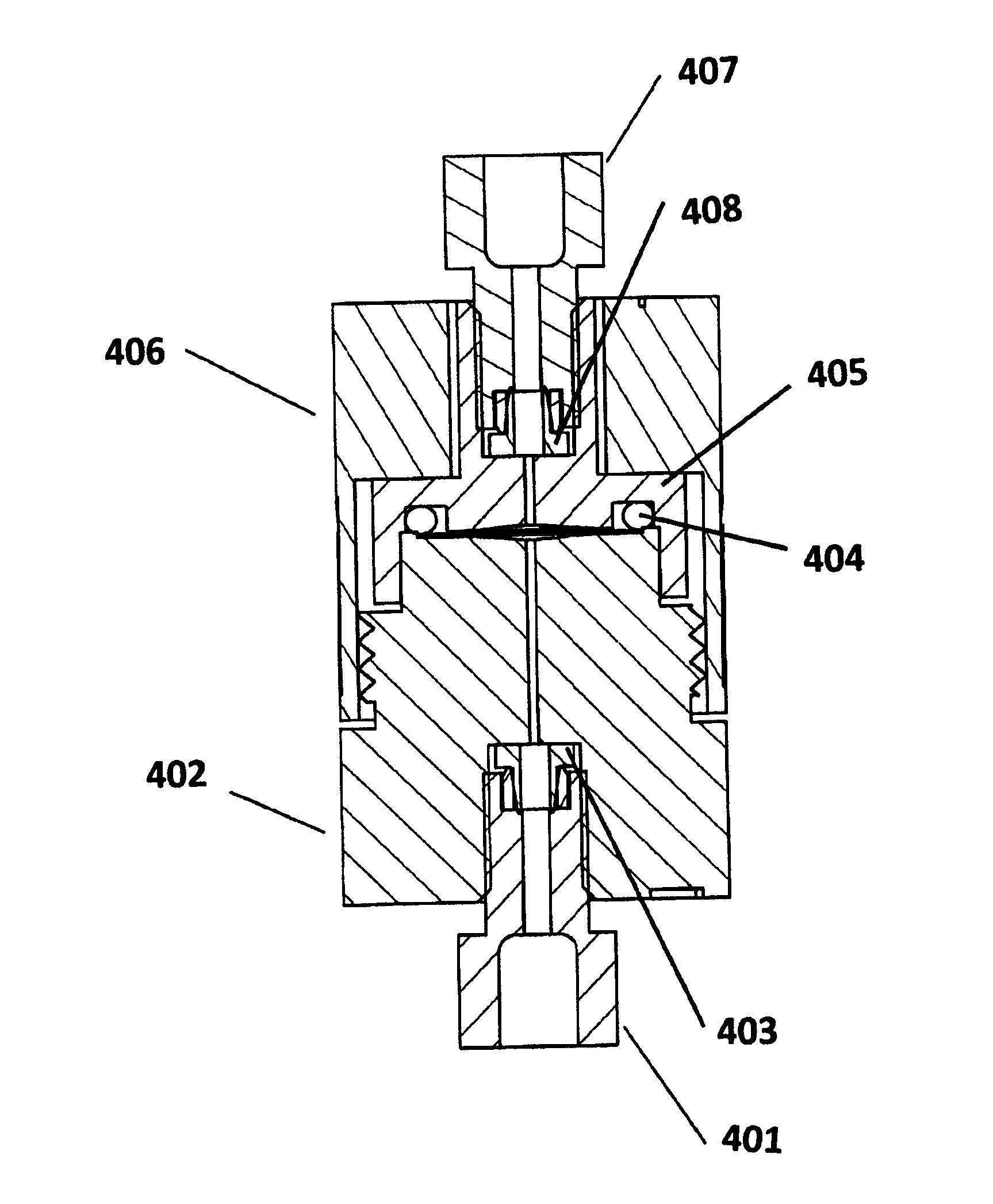

Automated Analyzer with Low-Pressure In-Line Filtration

ActiveUS20120103074A1Compromising reliabilityCompromising accuracySamplingComponent separationParticulatesAutomated analyzer

An automated analyzer for biological samples that contain particulate matter is adapted to be able to process a large number of samples without changing the analytical cartridge, and in many cases without changing the internal switching valves, by including a filter in the low-pressure section of the analyzer, and preferably configuring the analyzer to be able to perform backflushing on the filter between sample injections.

Owner:BIO RAD LAB INC

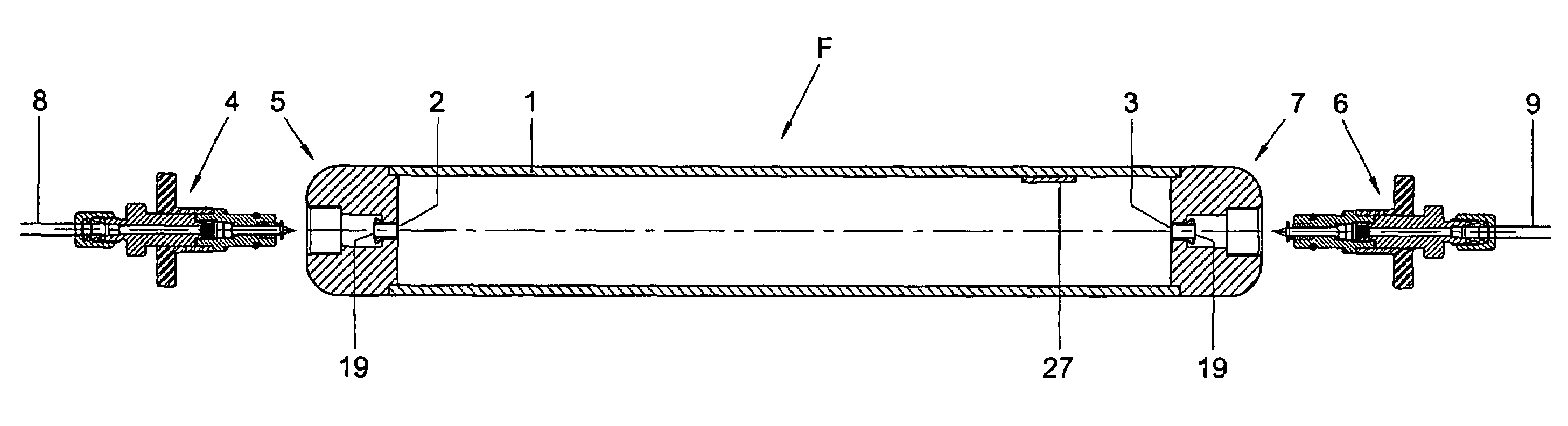

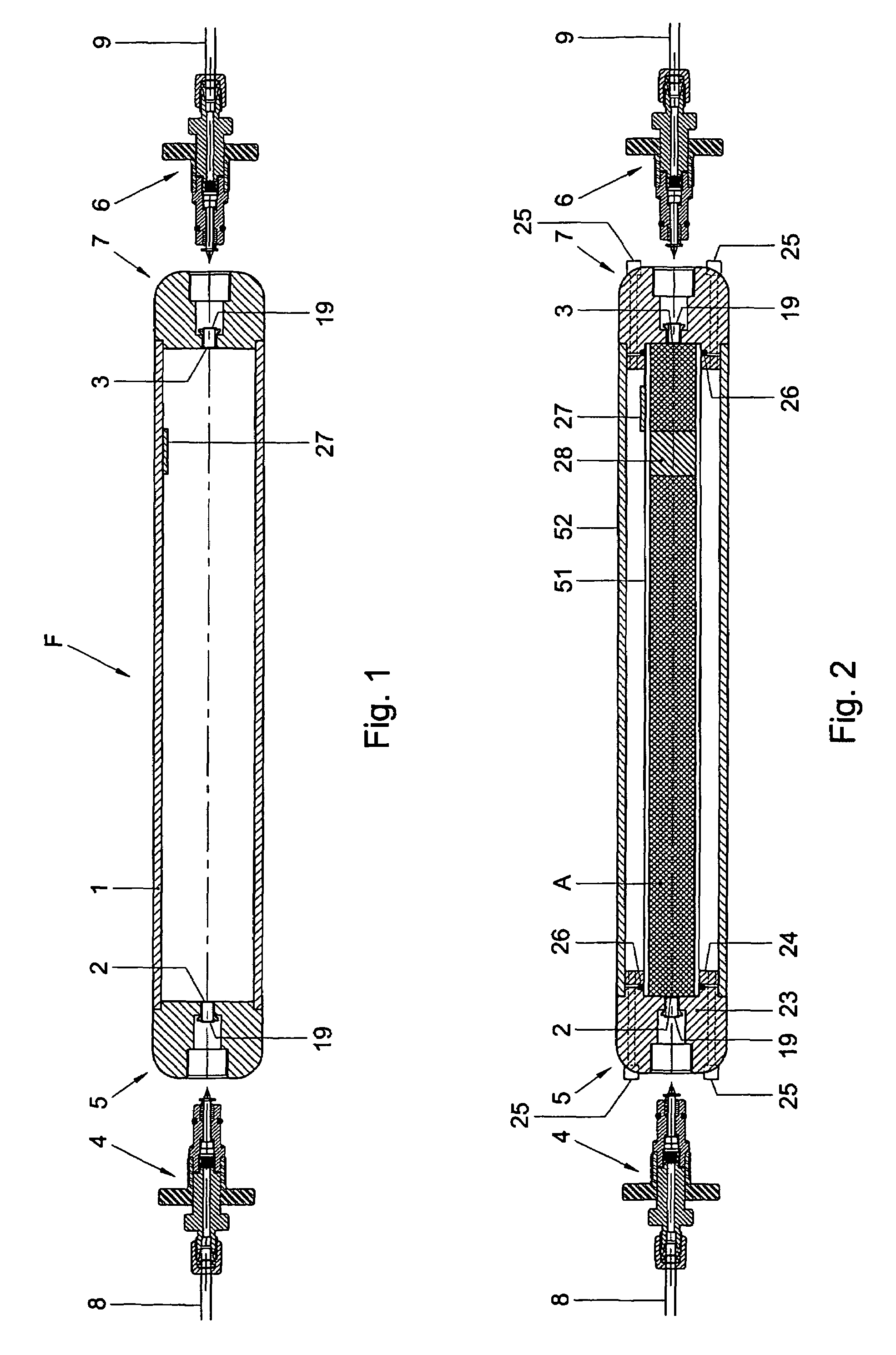

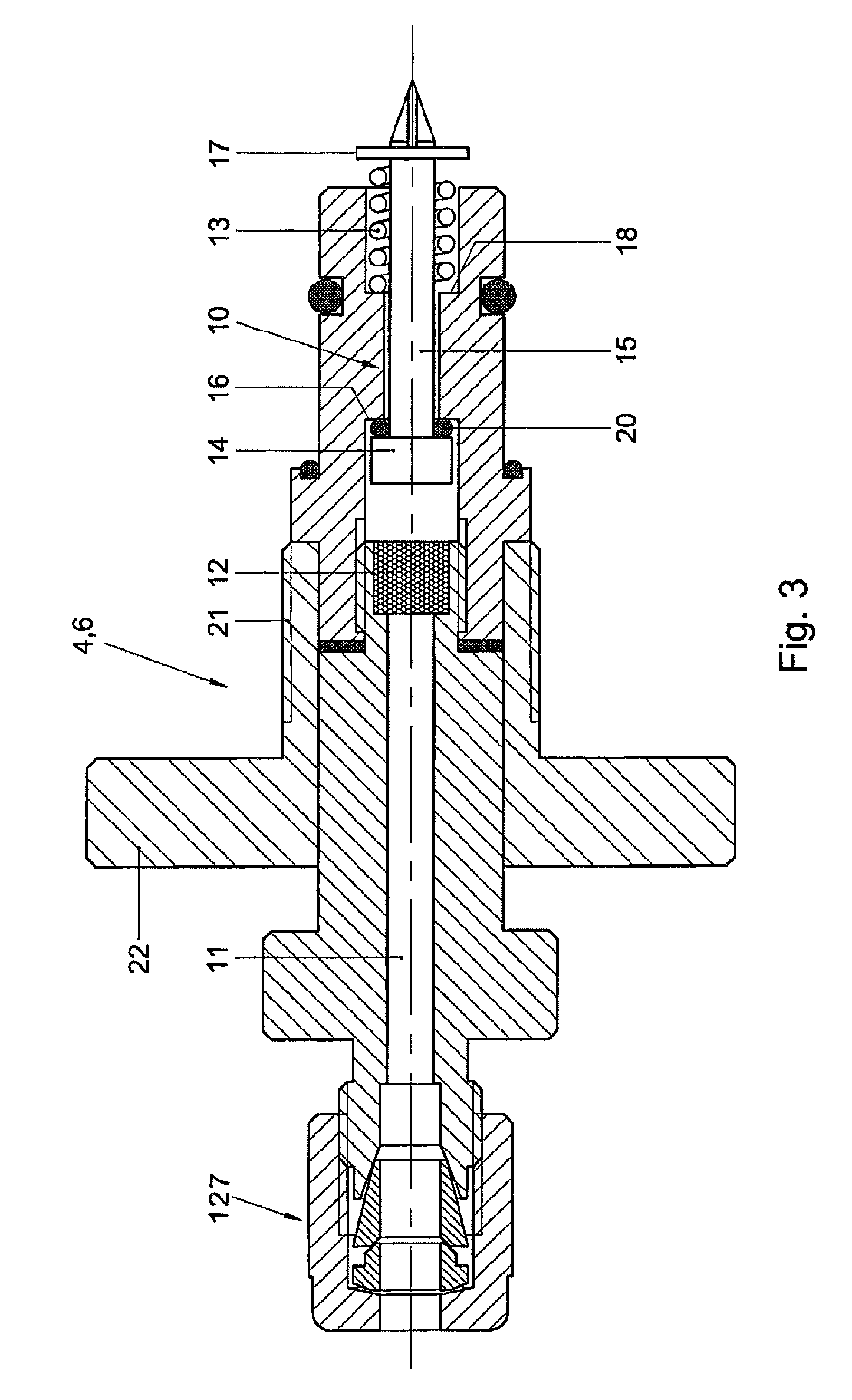

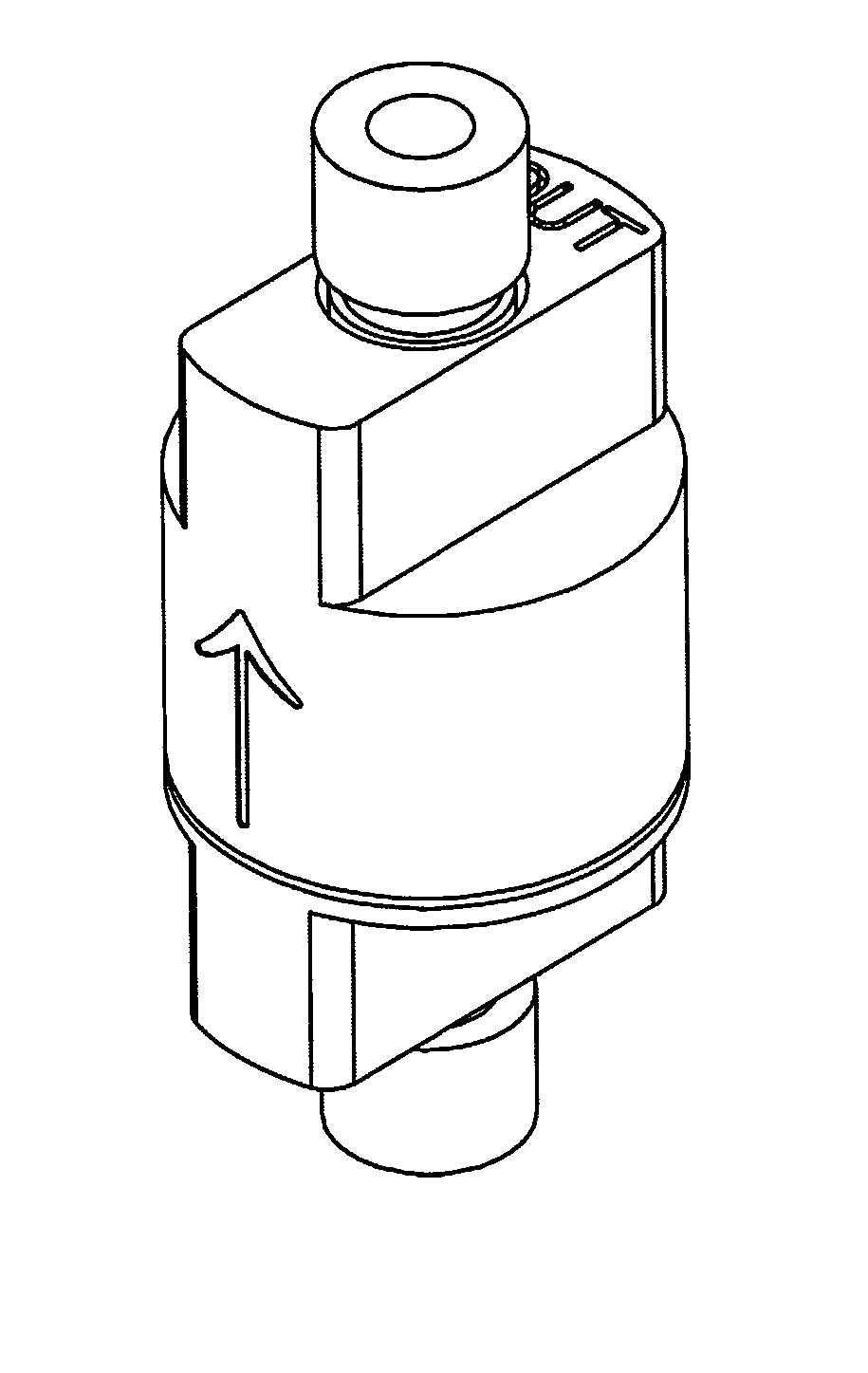

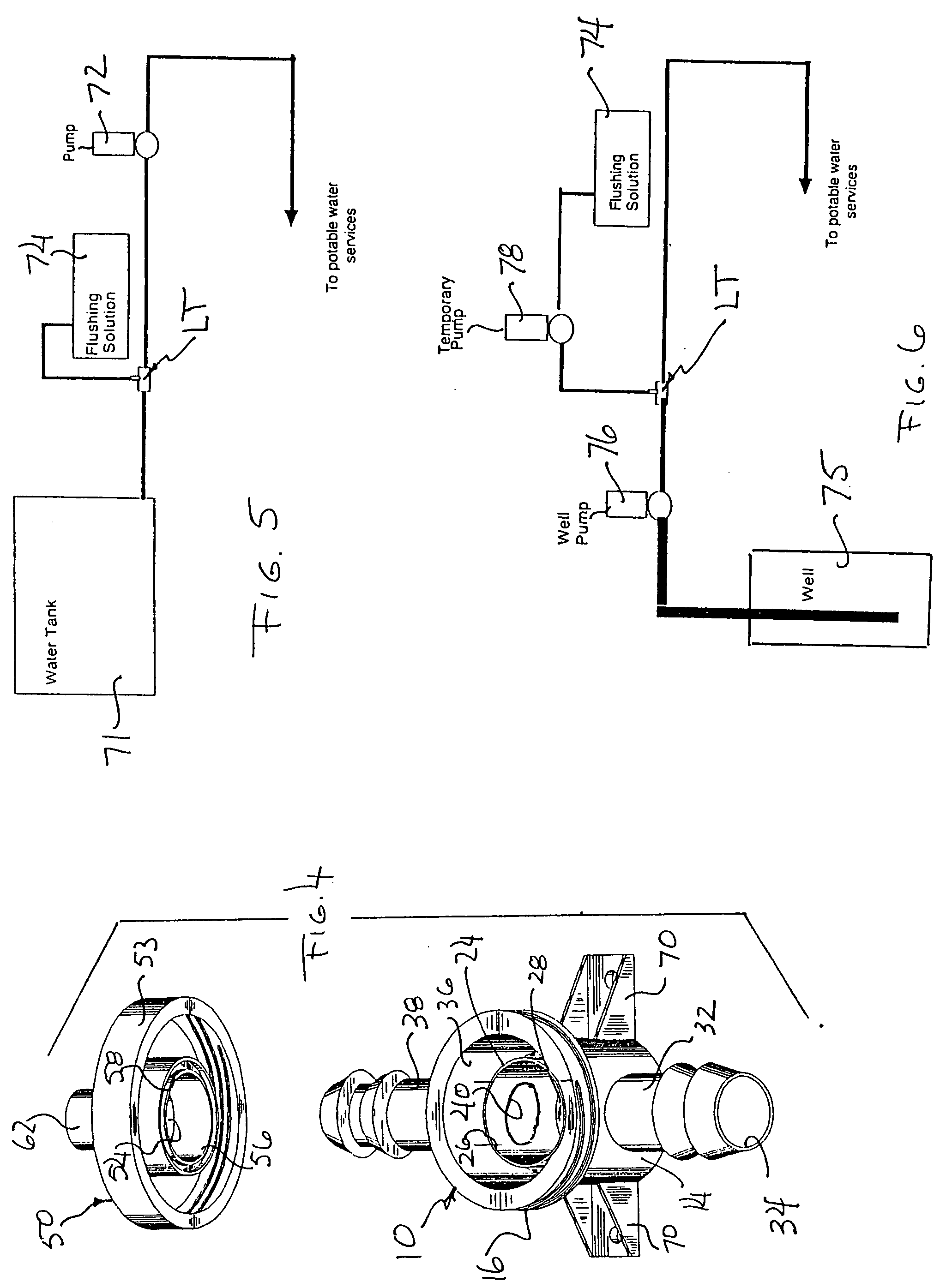

In-line filter with quick-change coupling and a filter

ActiveUS7608136B2Damage to dischargeDamage to supplyCombination devicesValve arrangementsCouplingFilter material

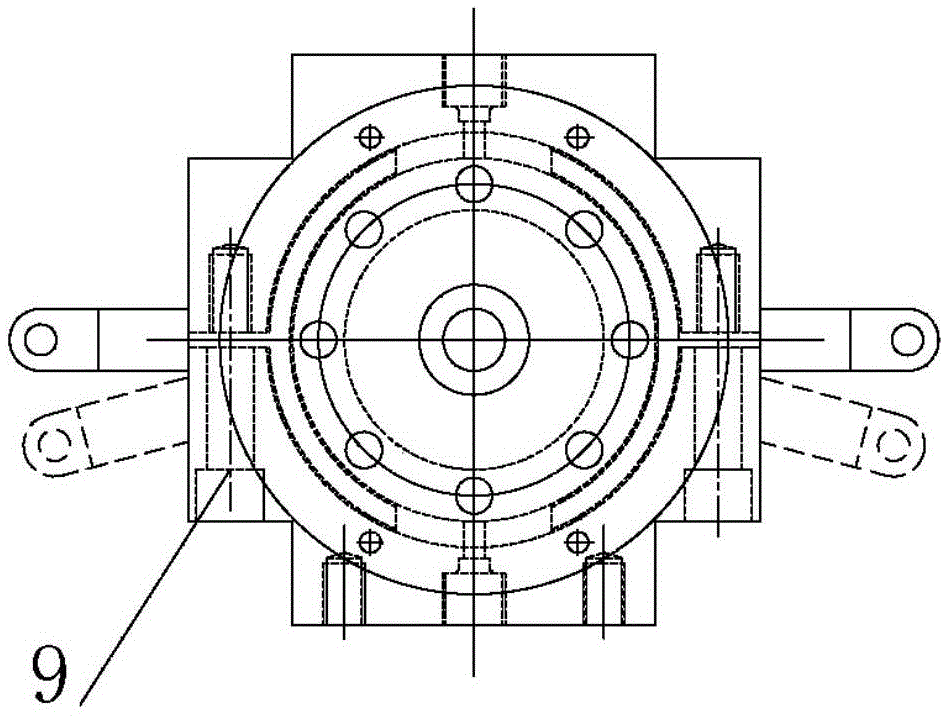

An in-line filter provided with a substantially elongated filter housing (1; 51) in which filtering material (A) is included, the filter housing being provided on a first end with an inflow opening (2) and, on a second, opposite end with an outflow opening (3), while at the inflow opening (2) and the outflow opening (3) fastening means (4-7) are provided for fastening a supply or discharge tube, respectively (8 or 9, respectively), while the fastening means (4-7) are quick-change couplings (4-7), a respective quick-change coupling (4, 5; 6, 7) having a coupled condition and an uncoupled condition, while in the quick-change coupling (4, 5; 6, 7) a shut-off valve (10) is provided which, in the coupled condition, assumes an open position thus allowing gas to pass and which, in an uncoupled condition, assumes a closed position thus not allowing gas to pass.

Owner:SCI GLASS TECH SINGAPORE PTE

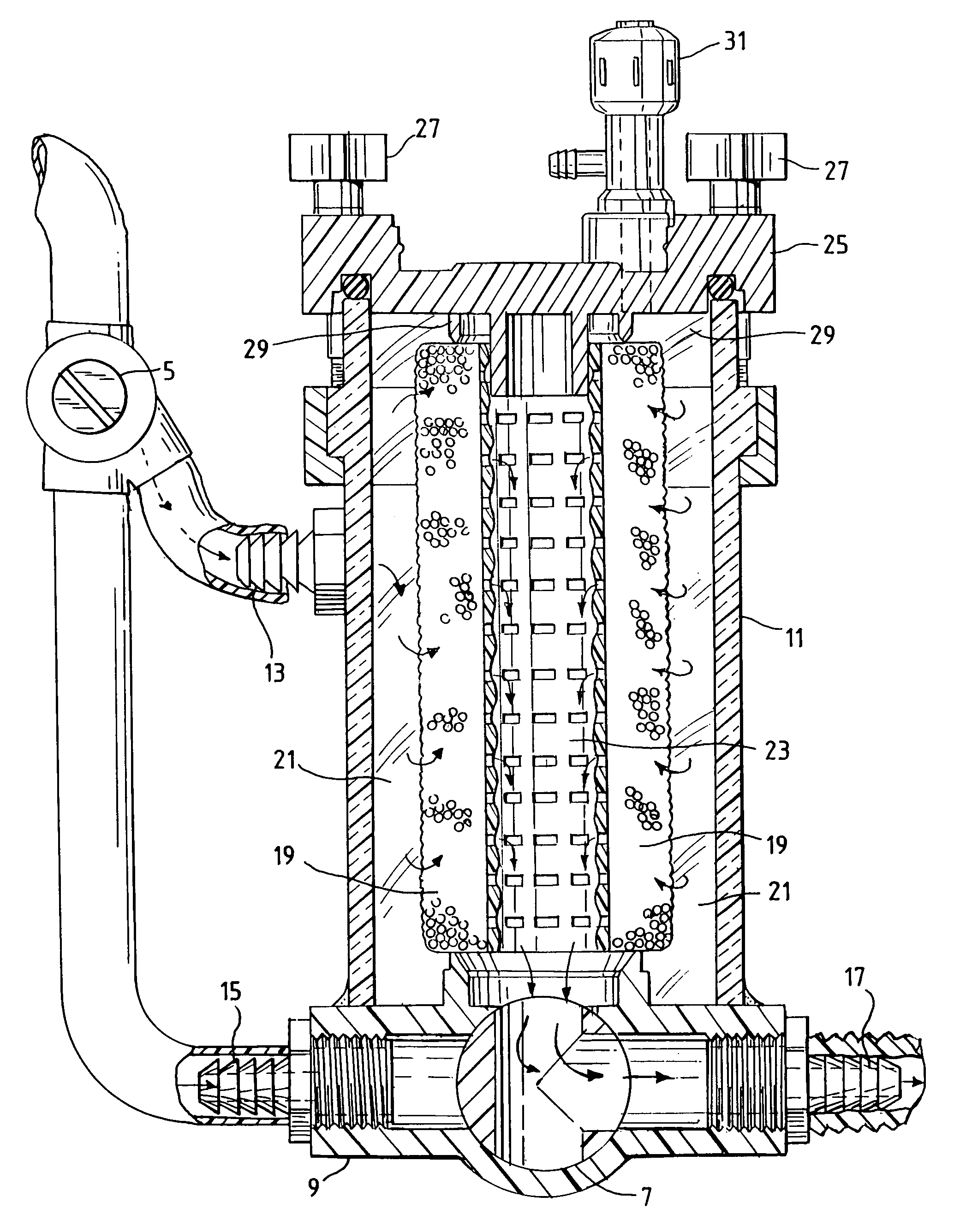

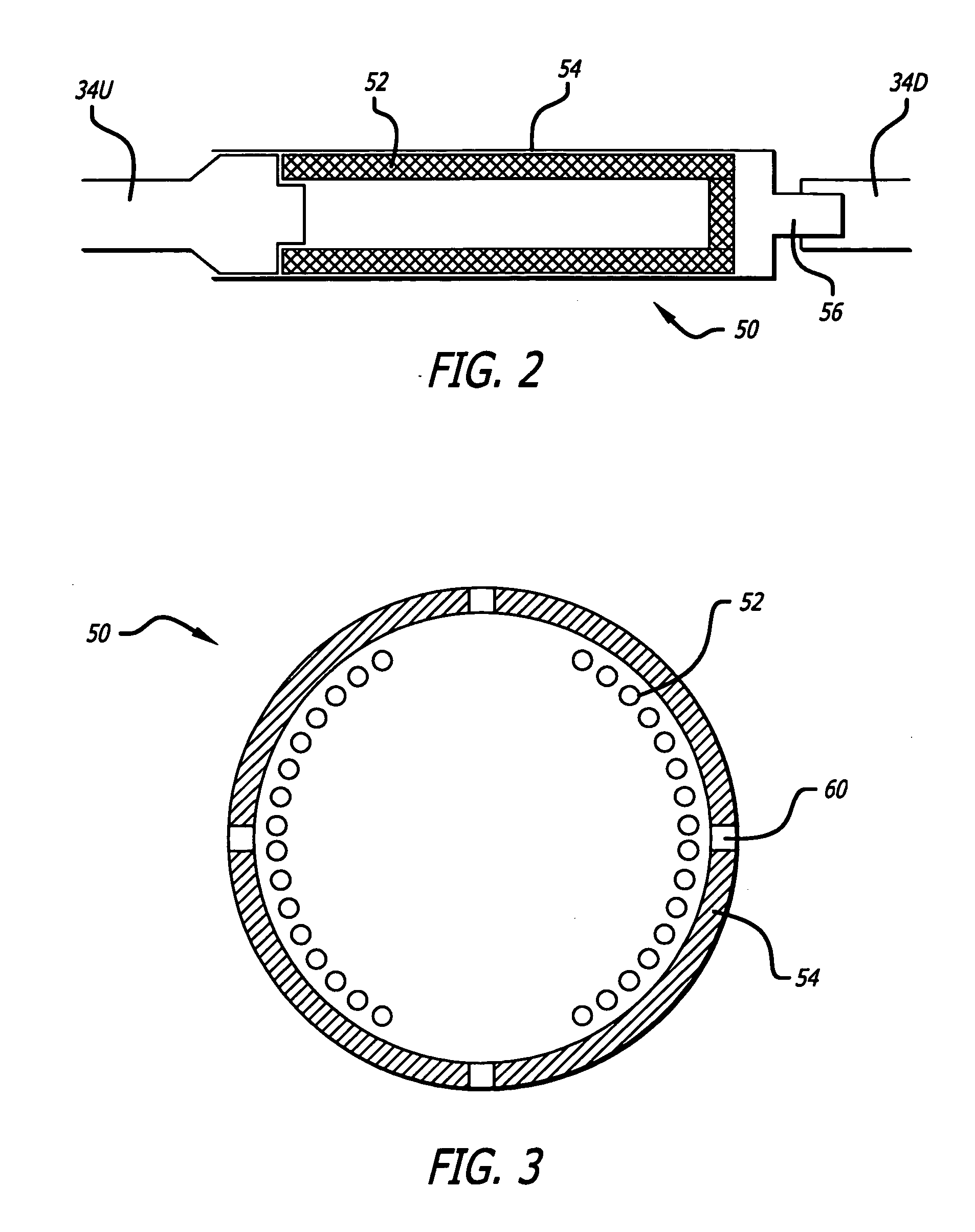

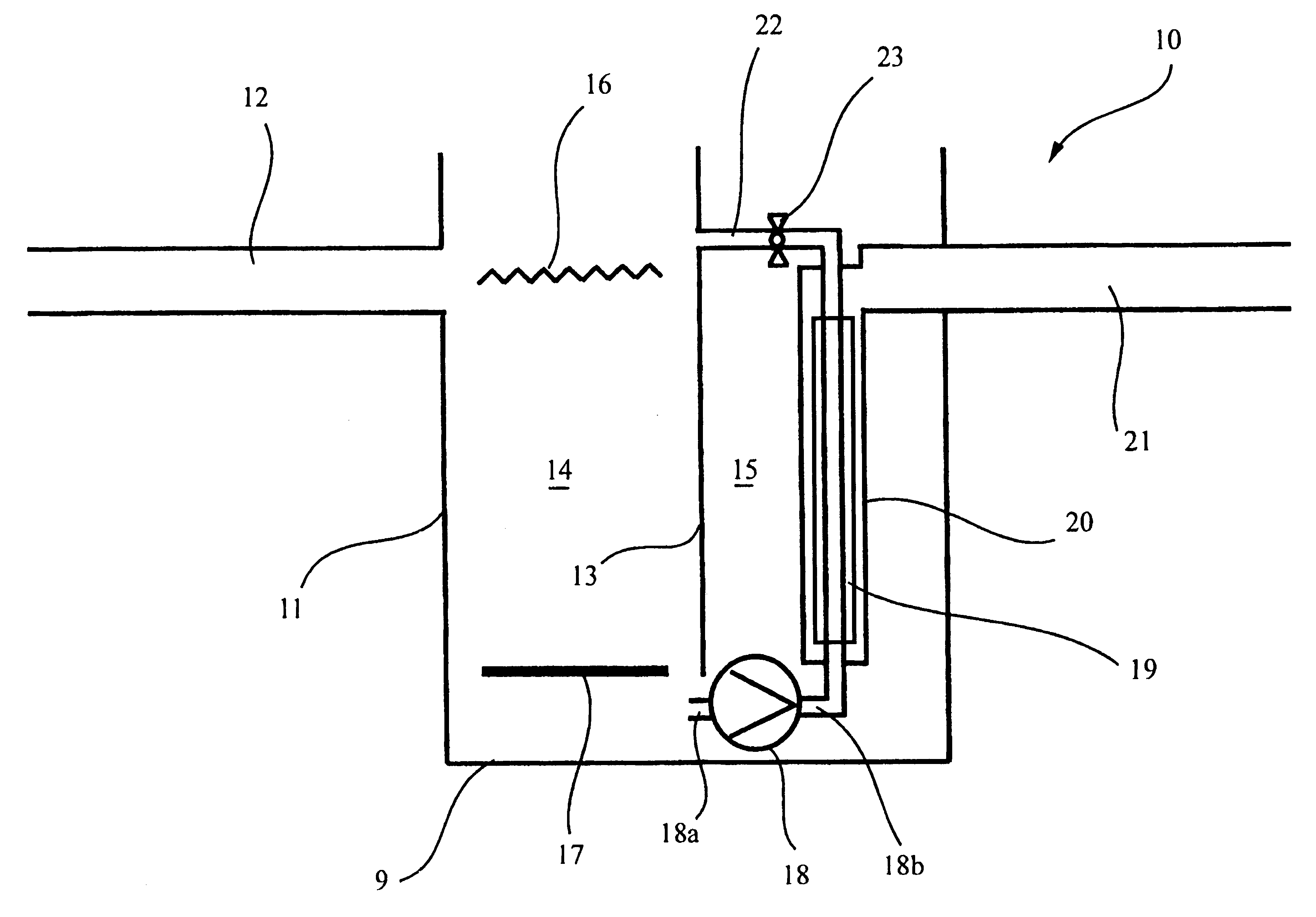

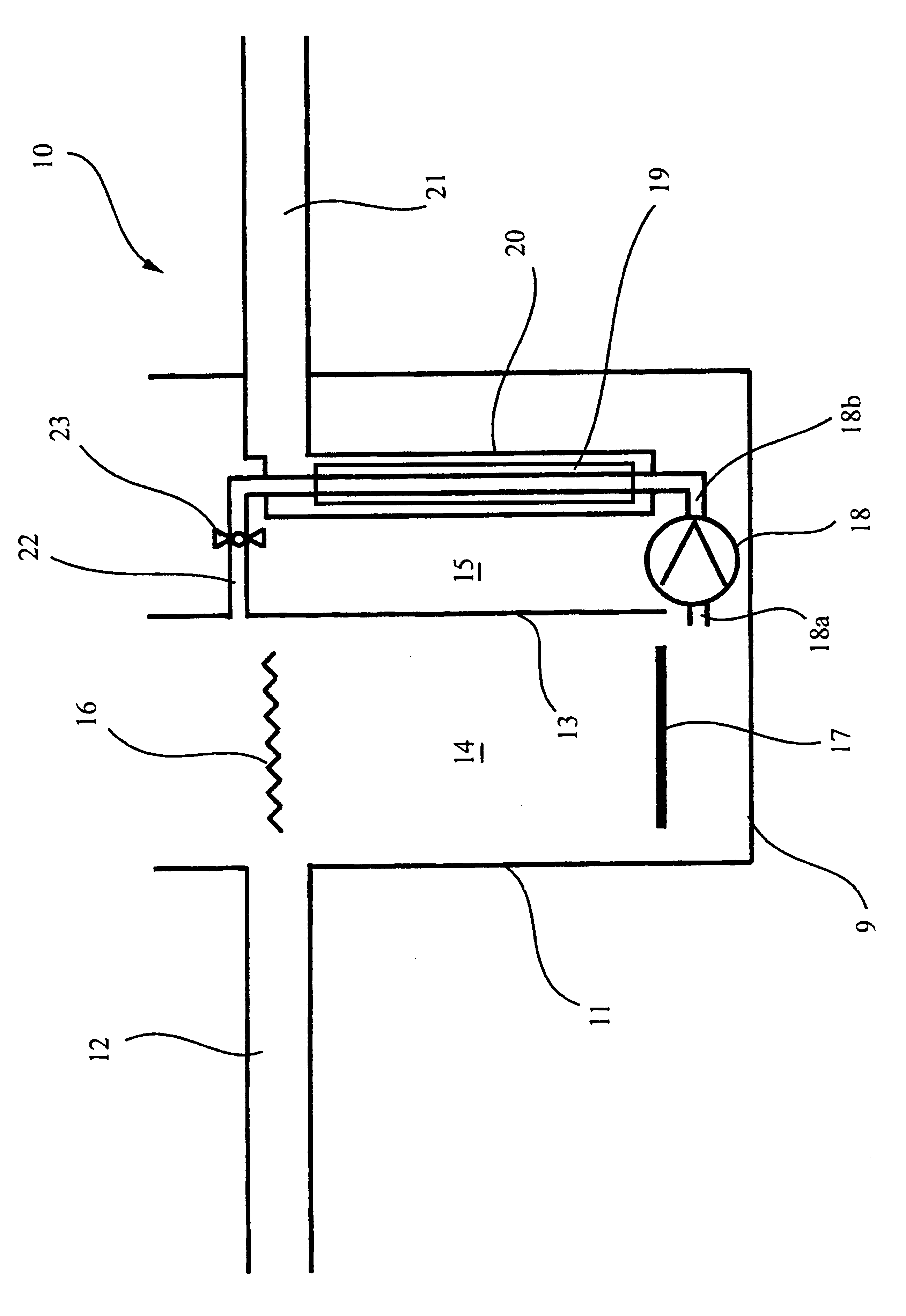

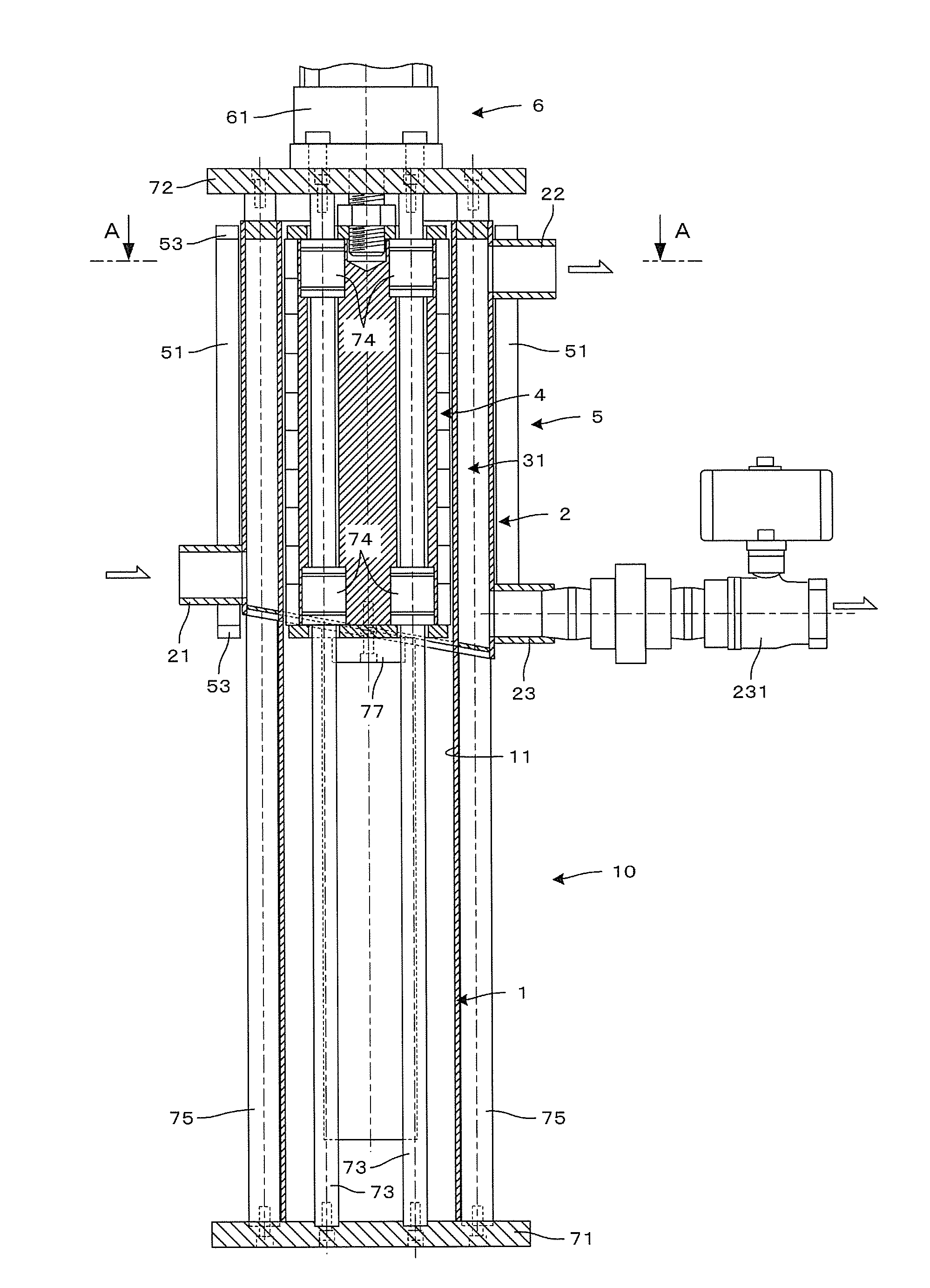

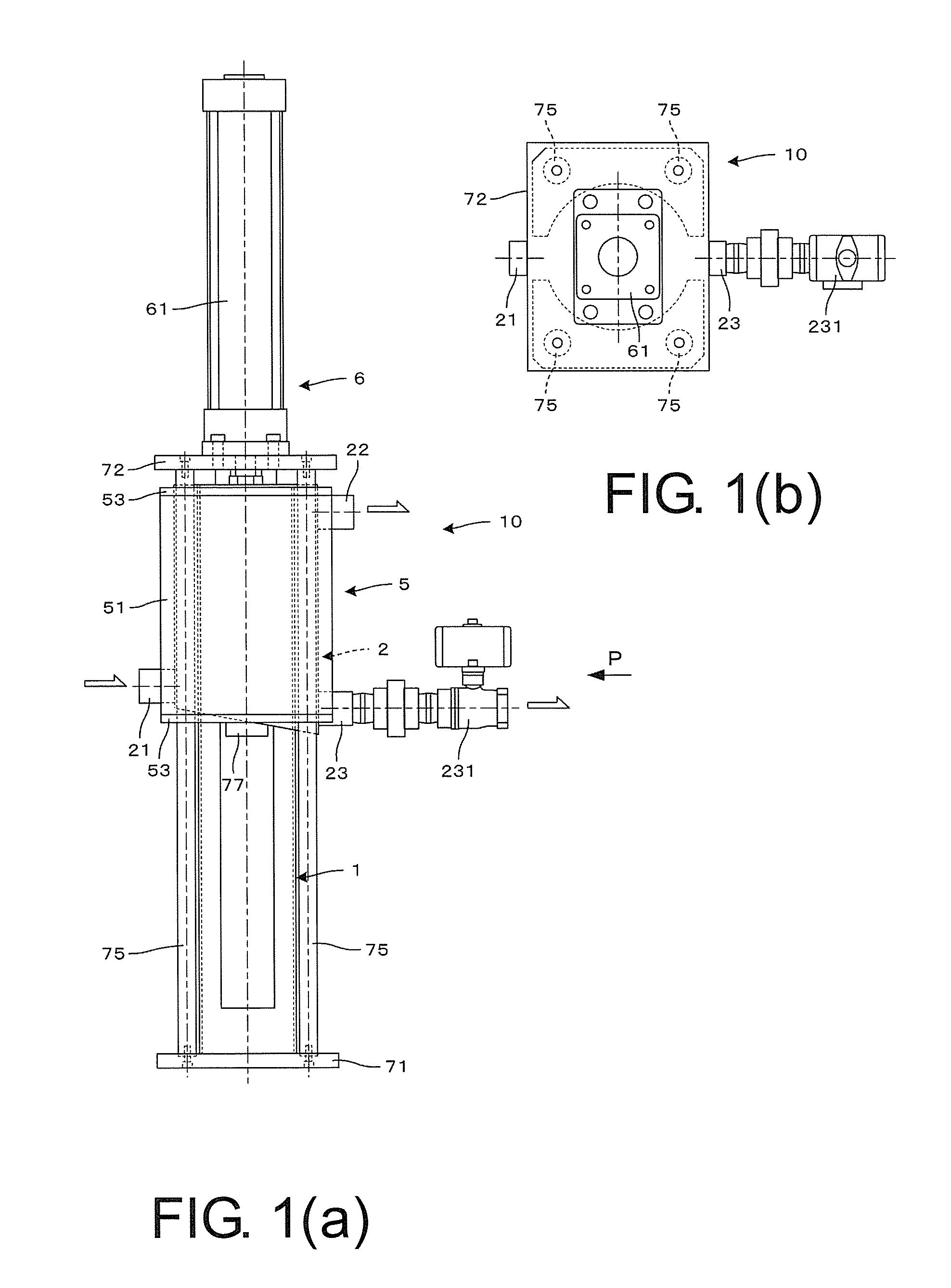

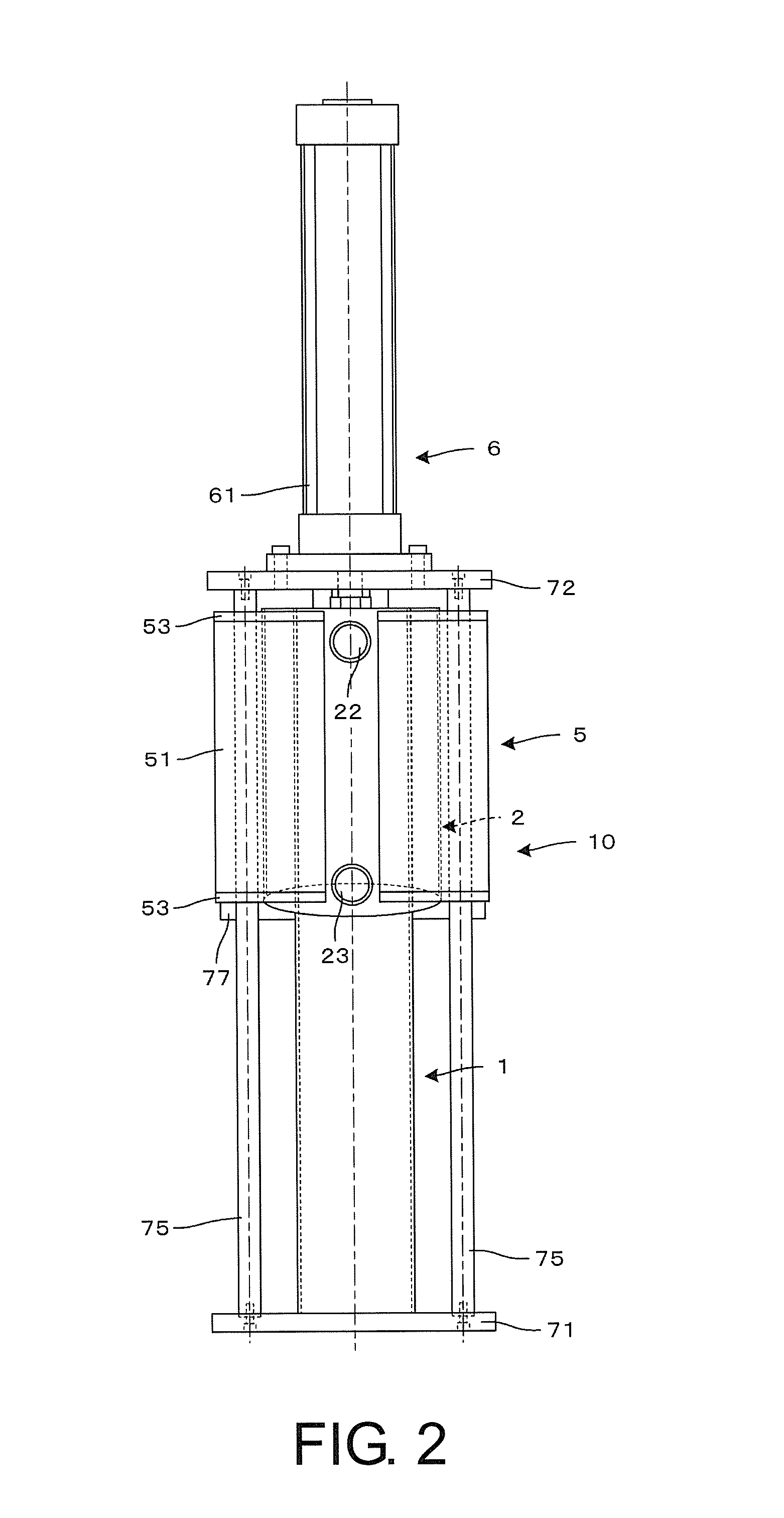

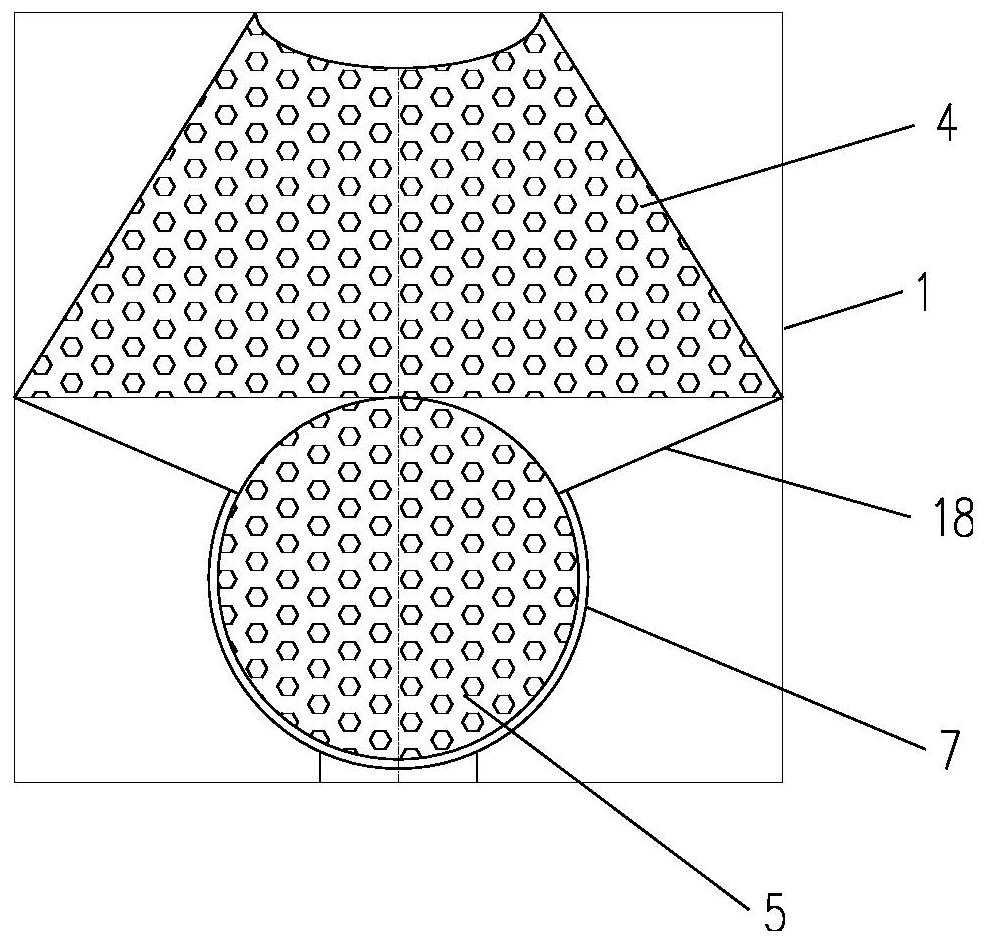

Method for in-line filtering of a liquid metal and implementing device

InactiveUS6468326B1Quality improvementImprove effectivenessBlast furnace detailsDischarge devicesLiquid stateRefractory

A device for an in-line filtering (10) of a liquid metal, by using only a single installation, to obtain a very good filtering of any liquid metal whatever its melting point. The device comprising a treating chamber (11) made of refractory material and having an inlet (12) for supplying the metal liquid to be filtered, an element for cleaning (16) the metal, and an element for degassing (17) the cleaned metal. The degassed metal is then injected, under pressure via an injection pump (18), into a porous filtering element (19) and injected liquid flows tangentially to a filtering surface of the filtering element (19) for filtering the metal while simultaneously cleaning the filtering surface. Under the effect of the applied pressure, a portion of the degassed metal passes through the filtering element (19), which is enclosed by a chamber (20), and the filtered liquid is evacuated through an output port (21) provided in the treating chamber (11). The unfiltered liquid metal, which contains all the impurities, is re-introduced back into the treating chamber (11), via a conduit (22) which includes pressure and flow regulator (23), for further processing. A method for in-line filtration of a liquid metal is also disclosed.

Owner:MEMBRATEC

Aluminum alloy 7A04 and hot-top casting technology thereof

ActiveCN104372216AReduce casting speedReduced propensity for center cracksLine filterMaterials science

The invention provides a hot-top casting technology of aluminum alloy 7A04. The hot-top casting technology includes A) smelting sources Cu, sources Mn, sources Mg, sources Cr, sources Zn, sources Ti, sources Be, and sources Al to obtain smelting material; B) subjecting the smelting material to on-line degassing, on-line filtering and on-line refining in order to obtain on-line processing material; C) subjecting the on-line processing material to casting at speed of 15-25mm / min to obtain the aluminum alloy 7A04, to be specific, the aluminum alloy 7A04 comprises 1.4-2.0% of Cu, 0.2-0.6% of Mn, 1.8-2.8% of Mg, 0.1-0.25% of Cr, 5.0-7.0% of Zn, 0-0.1% of Ti, 0-0.0009% of Be, and the balance of Al. The invention further provides the aluminum alloy 7A04.

Owner:SOUTHWEST ALUMINUM GRP

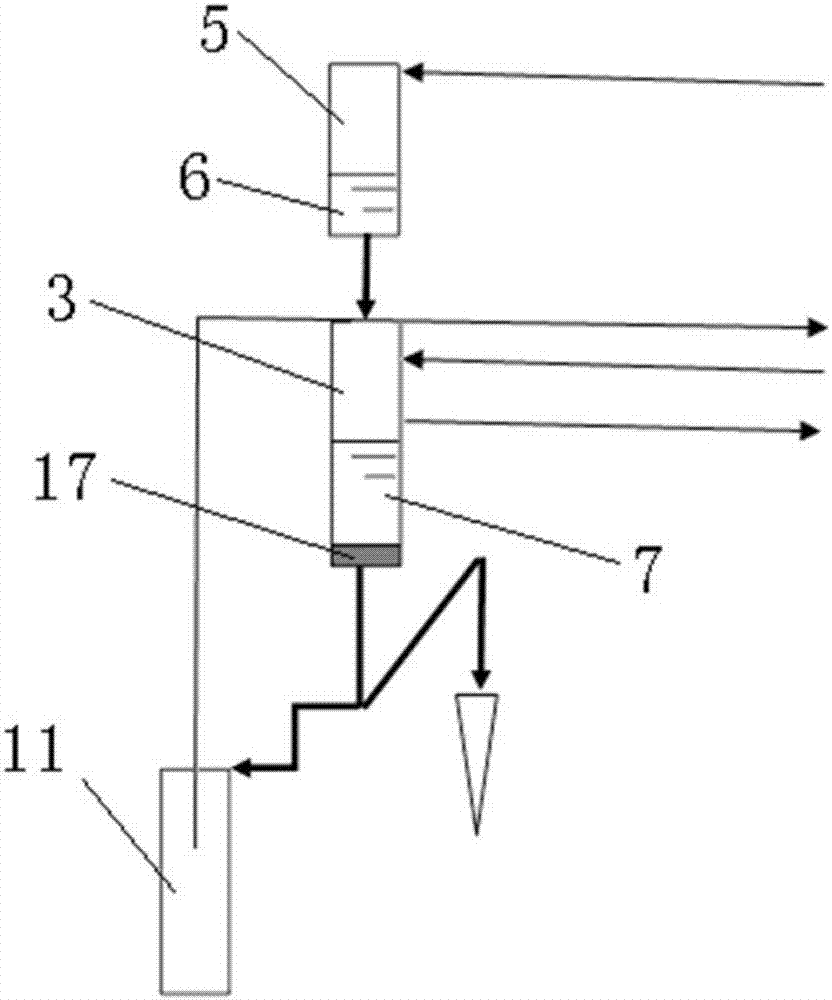

On-line collection and on-line automatic detection method of bacteria and viruses in air

ActiveCN106967595AQuick checkSensitive detectionBioreactor/fermenter combinationsBiological substance pretreatmentsPathogenic microorganismEngineering

The invention relates to an on-line collection and on-line automatic detection method of bacteria and viruses in air, by which in combination with a biochip or fluorescent quantitative PCR technology, possible pathogenic microorganisms in air can be quickly and sensitively detected. An on-line collection and on-line automatic detection device mainly comprises a negative-pressure air suction device, an air flow meter, an adsorbing solution and adsorbing particles. By use of the air suction device, through negative-pressure air suction, air runs through a liquid collection area at a constant air flow per minute; under the solution and the adsorbing particles in the solution, virus particles in air are collected in small-volume liquid; meanwhile, collected microorganisms are cracked to release DNAs (RNAs) of the microorganisms, and the microorganisms are adsorbed onto the adsorbing particles; then, through on-line filtration, the particles in the liquid are collected, the DNAs (RNAs) are eluted by using a commercially available DNA (RNA) eluent, then the microbial biomass is detected by a PCR technology, and the detected number of copies is divided by the volume of adsorbed air to obtain the detected number of microorganisms in unit air.

Owner:SHANGHAI DEJU BIOTECH CO LTD

Inline filter housing assembly

A novel filter housing assembly for use in liquid chromatography and similar fluid flow based systems capable of use at high pressure, well above 1000 psi, is disclosed. The filter housing assembly has a very low dead volume of approximately 11 μL and is capable of holding brittle ceramic filter membranes as well as flexible membranes without the support of a fit. The filter housing is capable of being assembled and disassembled by hand without the need of any tools and makes use of an inexpensive, disposable filter retaining screen.

Owner:WYATT TECH

Aluminum alloy 7050 and hot-top casting technology thereof

The invention provides a hot-top casting technology of aluminum alloy 7050. The hot-top casting technology includes A) smelting sources Cu, sources Mn, sources Mg, sources Cr, sources Zn, sources Ti, sources Be, sources Zr and sources Al to obtain smelting material; B) subjecting the smelting material to on-line degassing, on-line filtering and on-line refining in order to obtain on-line processing material; C) subjecting the on-line processing material to casting at speed of 15-25mm / min to obtain the aluminum alloy 7050, to be specific, the aluminum alloy 7050 comprises 0-2.6% of Cu, 0-0.6% of Mn, 1.1-3.0% of Mg, 0-0.3% of Cr, 4.4-8% of Zn, 0-0.06% of Ti, 0-0.0009% of Be, 0-0.25% of Zr and the balance of Al. The invention further provides the aluminum alloy 7050.

Owner:SOUTHWEST ALUMINUM GRP

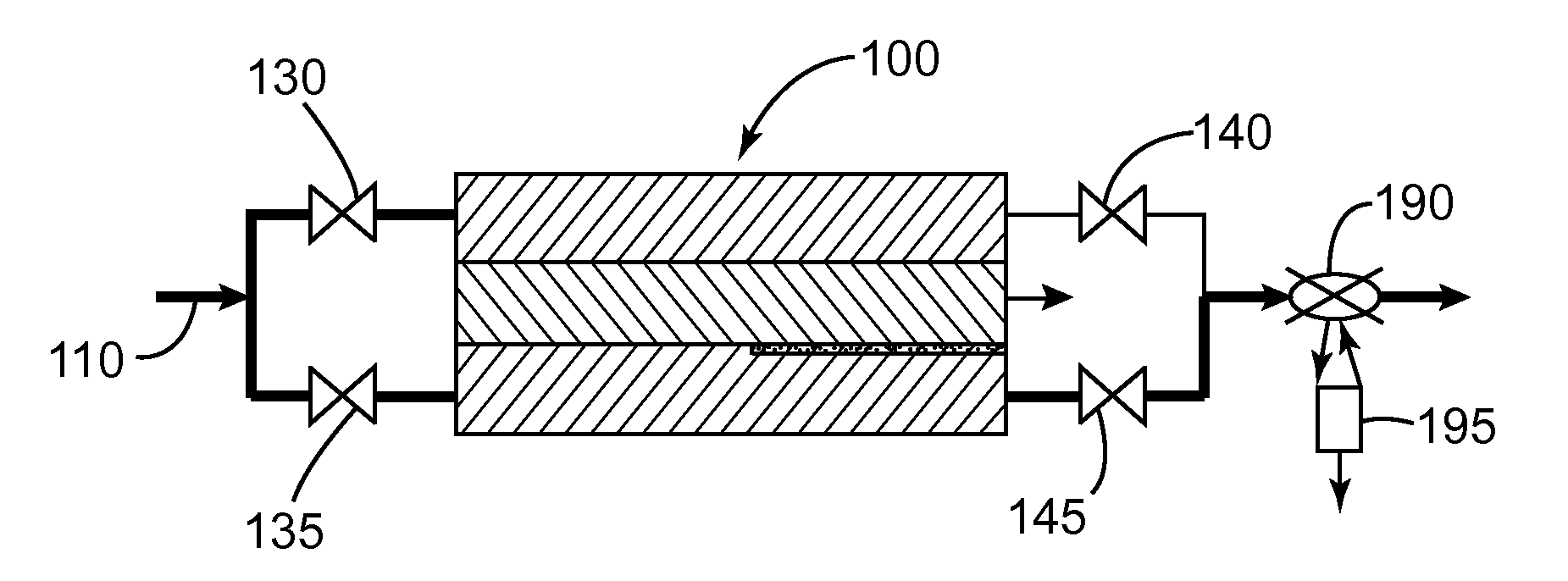

Low volume in-line filtration method for evaluation of asphaltenes for hydrocarbon-containing feedstock

ActiveUS20160169858A1Improve sharpnessGood symmetrySamplingComponent separationSolubilityIn line filtration

Disclosed herein is a method involving the steps of method for determining asphaltene stability in a hydrocarbon-containing sample having solvated asphaltenes therein, the method comprising the steps of: (a) precipitating an amount of asphaltenes from a liquid sample of the hydrocarbon-containing sample having solvated asphaltenes therein with one or more first solvents and capturing the precipitated asphaltenes in one or more low volume filters comprising a porous filter element comprising an area through which a fluid may flow; (b) determining one or more solubility characteristics of the precipitated asphaltenes; and (c) analyzing the one or more solubility characteristics of the precipitated asphaltenes.

Owner:CHEVROU USA INC

Low volume in-line filtration method for evaluation of asphaltenes for hydrocarbon-containing feedstock

ActiveUS9671384B2Improves sharpness and symmetryPoor symmetryComponent separationPreparing sample for investigationSolubilityIn line filtration

Disclosed herein is a method involving the steps of method for determining asphaltene stability in a hydrocarbon-containing sample having solvated asphaltenes therein, the method comprising the steps of: (a) precipitating an amount of asphaltenes from a liquid sample of the hydrocarbon-containing sample having solvated asphaltenes therein with one or more first solvents and capturing the precipitated asphaltenes in one or more low volume filters comprising a porous filter element comprising an area through which a fluid may flow; (b) determining one or more solubility characteristics of the precipitated asphaltenes; and (c) analyzing the one or more solubility characteristics of the precipitated asphaltenes.

Owner:CHEVROU USA INC

In-line filtration for a particle-based electrochemical

Owner:TECK COMINCO METALS LTD

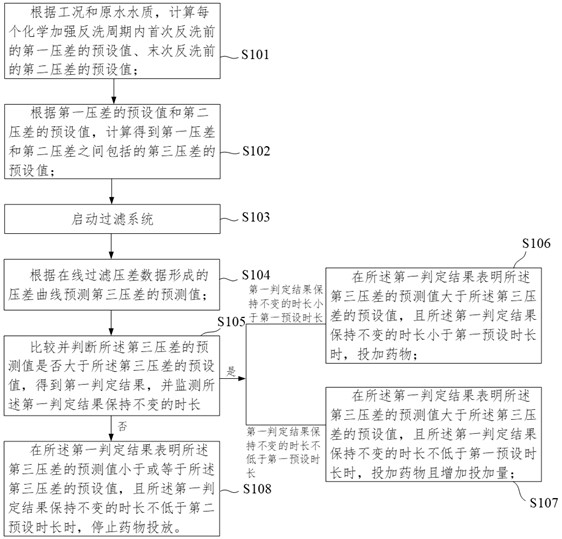

Ultrafiltration micro-flocculation accurate dosing control method and system

ActiveCN113044928AReduce dosageExtended chemical cleaning cycleWater treatment parameter controlMembranesFlocculationThermodynamics

The invention relates to the technical field of sewage treatment, and in particular, relates to an ultrafiltration micro-flocculation accurate dosing control method and system. The method comprises the steps: calculating a preset value of a first pressure difference before first backwashing and a preset value of a second pressure difference before last backwashing in each chemical enhanced backwashing period; calculating to obtain a preset value of a third pressure difference between the first pressure difference and the second pressure difference; predicting a predicted value of the third pressure difference; and comparing the preset value of the third pressure difference with the predicted value of the third pressure difference, and judging whether the chemical is continuously added or not. In the method provided by the invention, the preset value of the third pressure difference is obtained according to the preset value of the first pressure difference and the preset value of the second pressure difference, the predicted value of the third pressure difference is predicted according to the pressure difference curve formed by the online filtration pressure difference data, and the ultrafiltration operation state can be speculated by comparing the preset value of the third pressure difference and the predicted value of the third pressure difference; and the dosing state or dosage of a chemical can be adjusted in time according to the running state of ultrafiltration, so that good and stable running of an ultrafiltration system is ensured.

Owner:GREENTECH ENVIRONMENTAL CO LTD

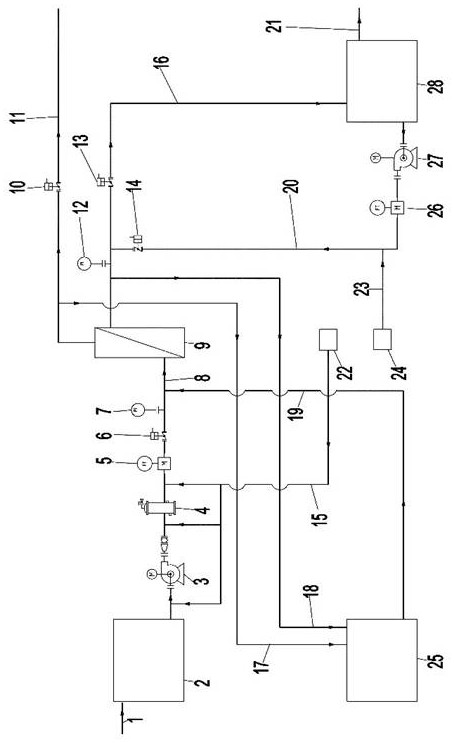

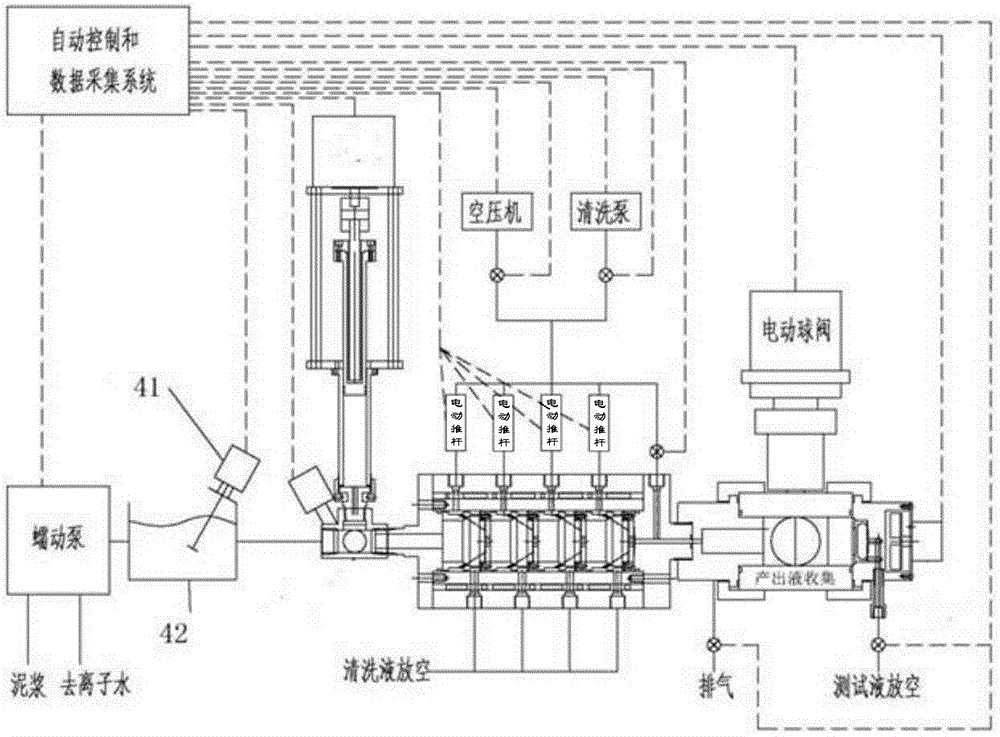

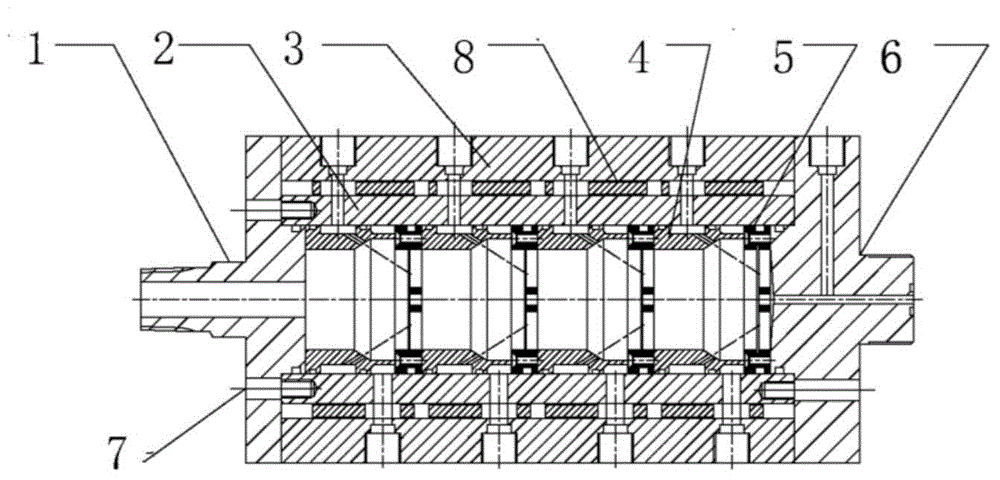

Online filtering device of drilling mud

InactiveCN104792601AImprove controllabilityBroad application spacePreparing sample for investigationFiltration circuitsHuman–machine interfaceIn line filtration

The invention discloses an online filtering device of drilling mud. The online filtering device comprises a self-priming pump, a filter holder, a produced fluid collecting device and a PLC controller, wherein the self-priming pump is connected with an inlet of the filter holder; a filter reverse-cleaning device sleeves the filter holder; an outlet of the filter holder is connected with the produced fluid collecting device; the PLC controller is communicated with and controls the self-priming pump, the filter holder, the produced fluid collecting device and the filter reverse-cleaning device respectively through a relay; the PLC controller is further connected with a human-machine interface for artificially controlling the operation state of the online filtering device of drilling mud. The online filtering device can sample automatically, continuously filter fluids in a well in an online manner, collect the filtrate and prepare for the subsequent online monitoring of ions, and has good controllability and broad application space.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

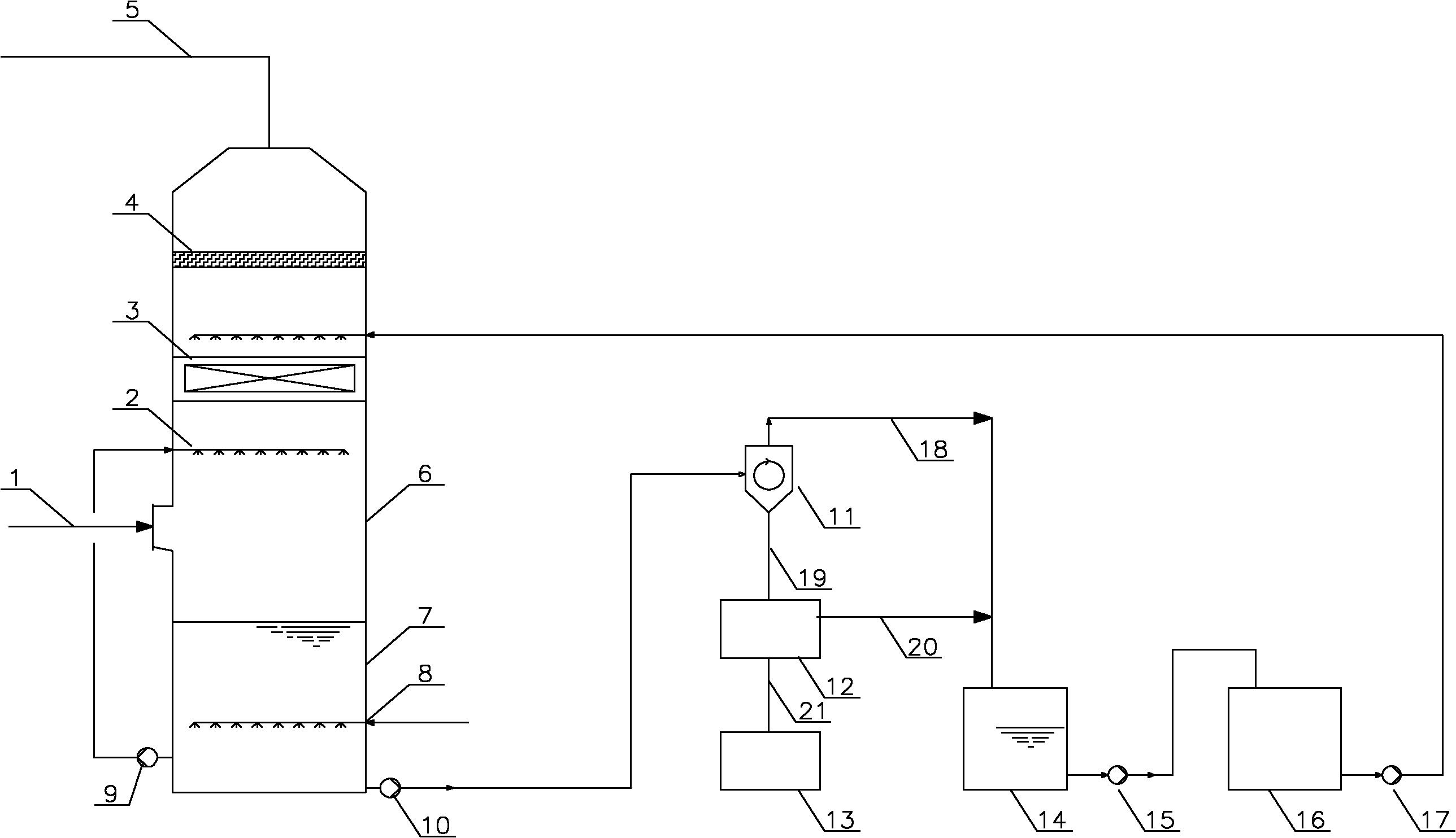

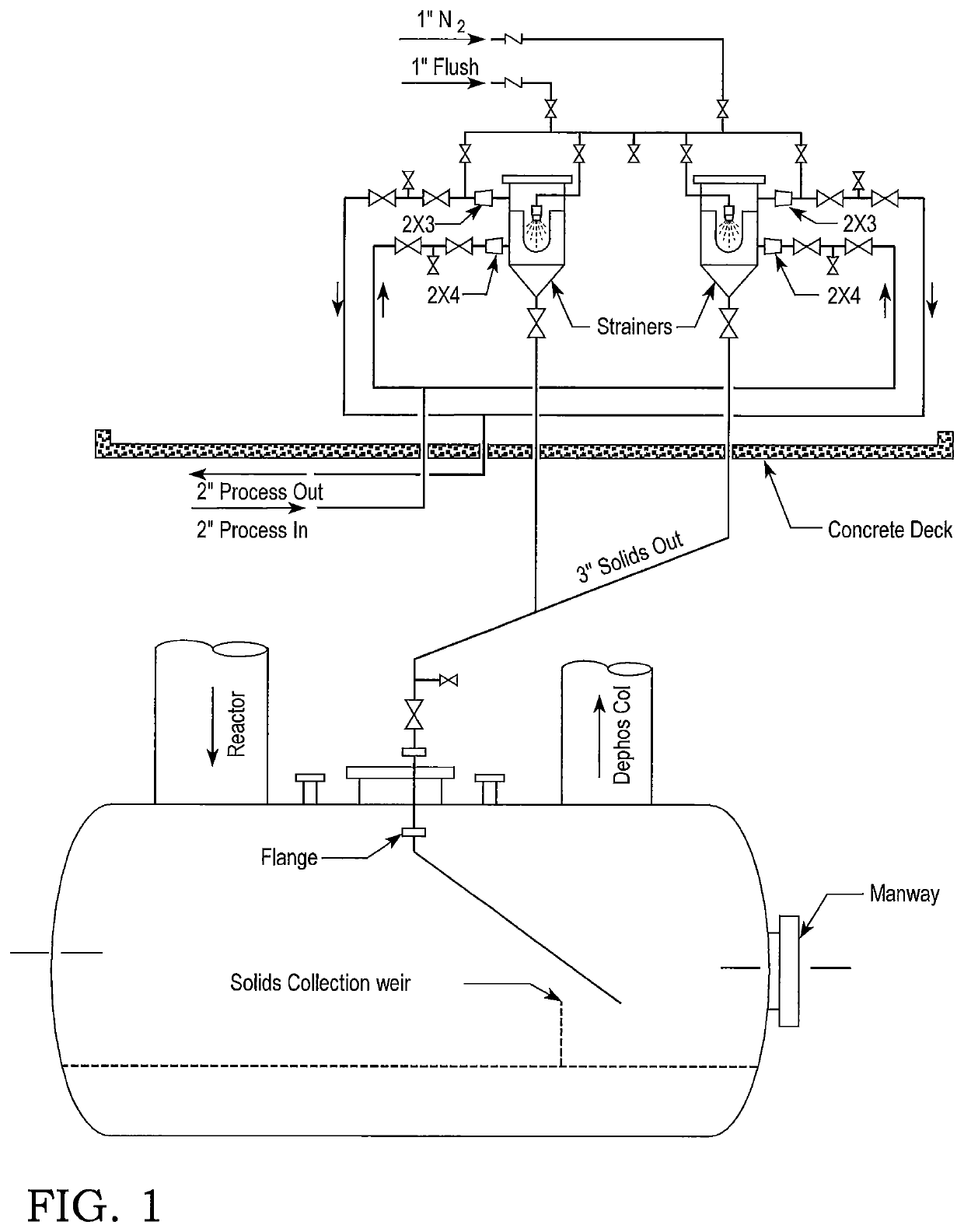

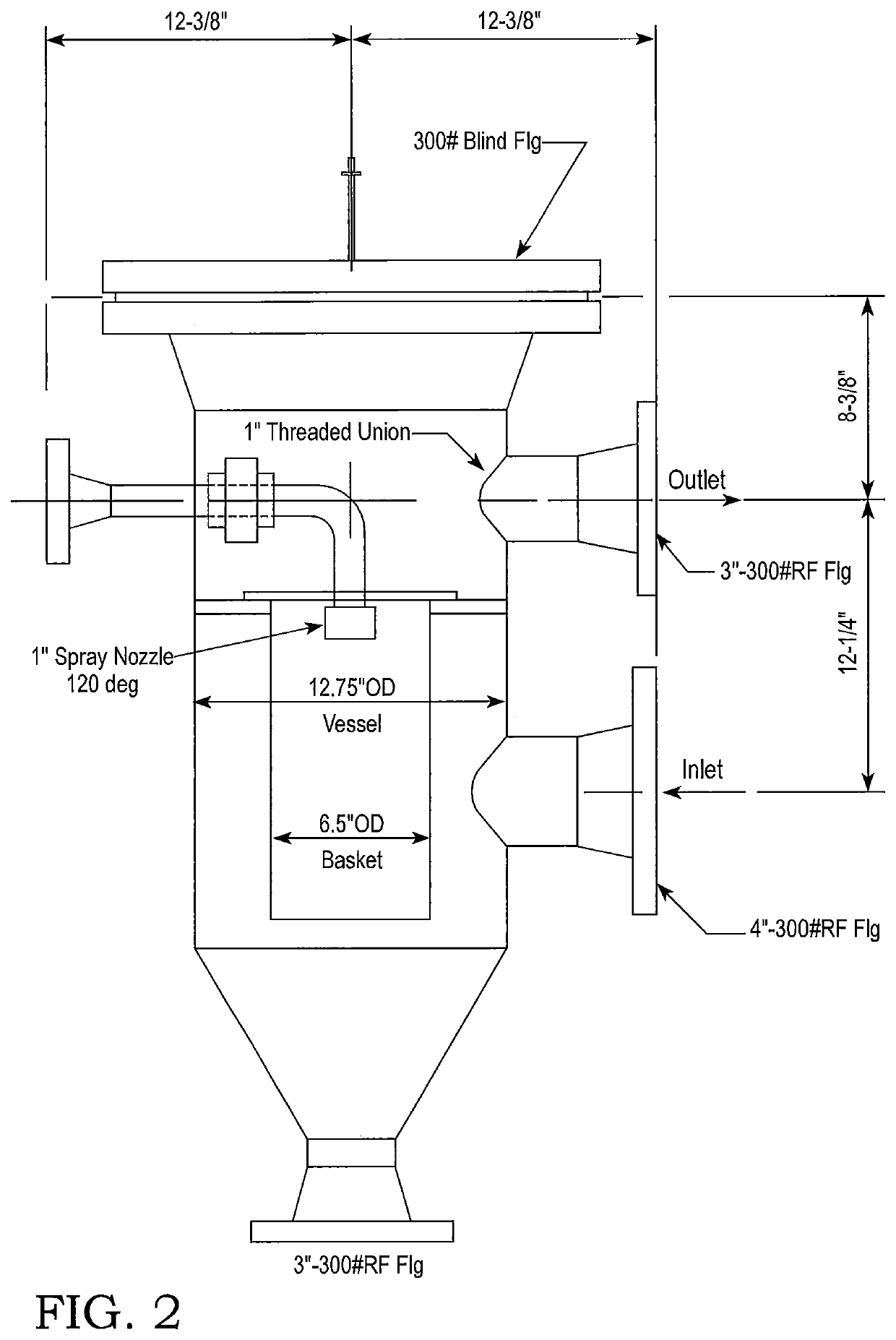

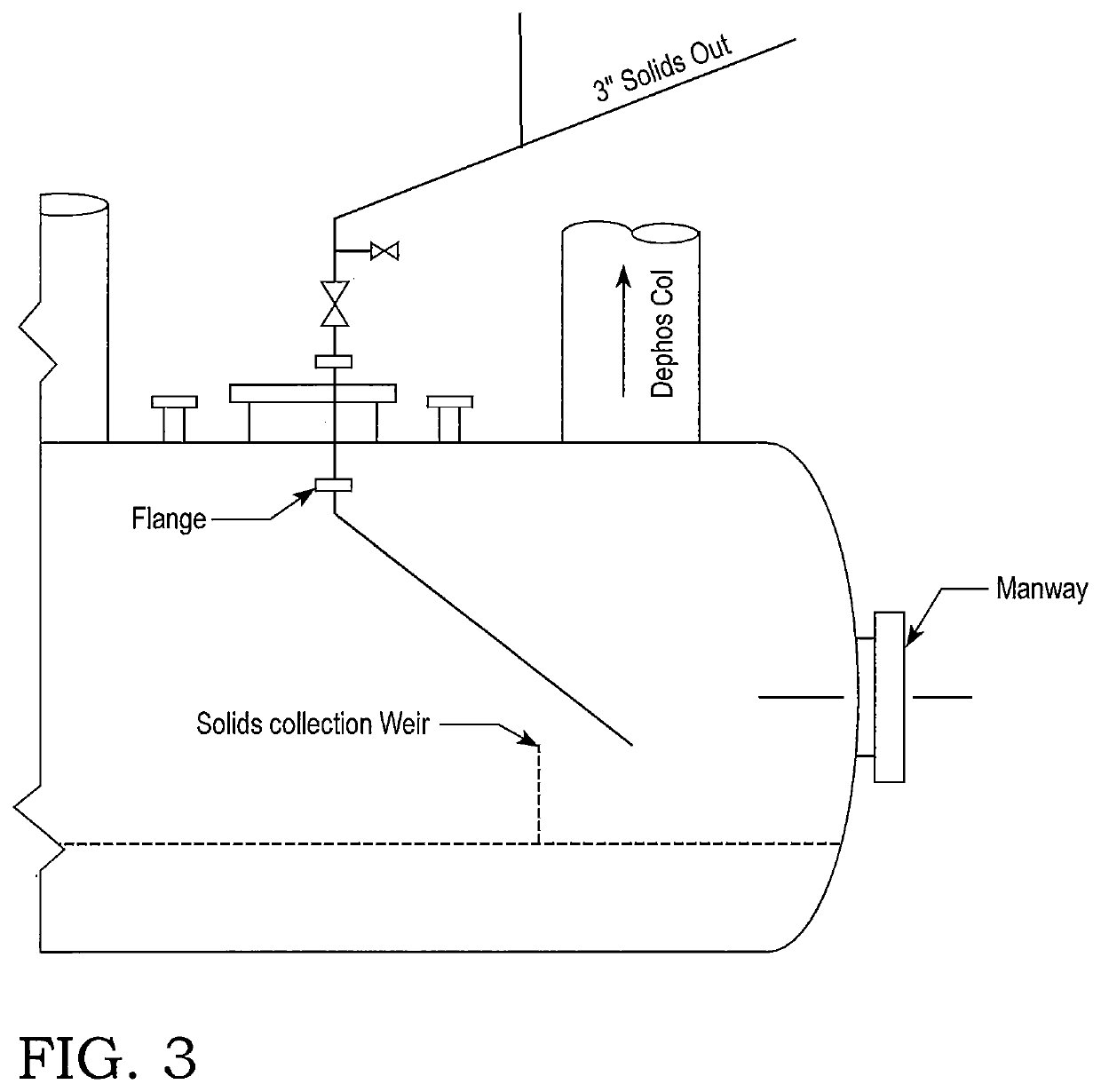

Process for the continual inline filtration of a process stream

ActiveUS10751649B2Ensure labor safetyStationary filtering element filtersProcess systemsFilter system

The present invention provides a new type of filtration system. Traditional designs required that personnel open the system to clean / change strainers while a process was in operation. This invention provides a straining system that allows process stream to be filtered in a manner completely internal to the process. The system includes dual strainers with a nitrogen purging system and solvent flush system. A creatively designed “catch” area is installed internal to the process to collect all solids that are flushed from the strainer system. The system remains completely closed for the duration of each production campaign, thus eliminating the safety hazard and labor requirement associated with opening a process system.

Owner:COVESTRO LLC +1

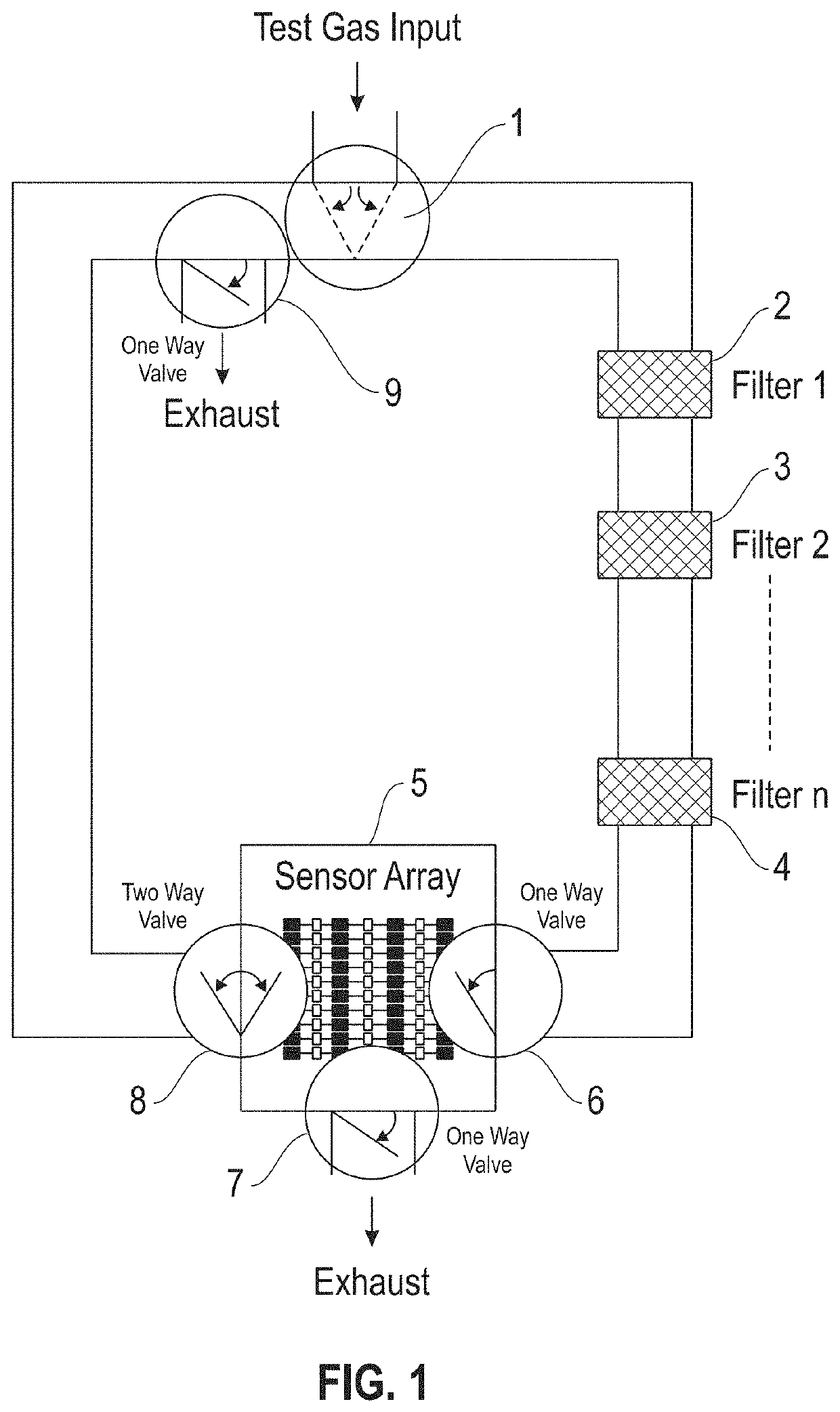

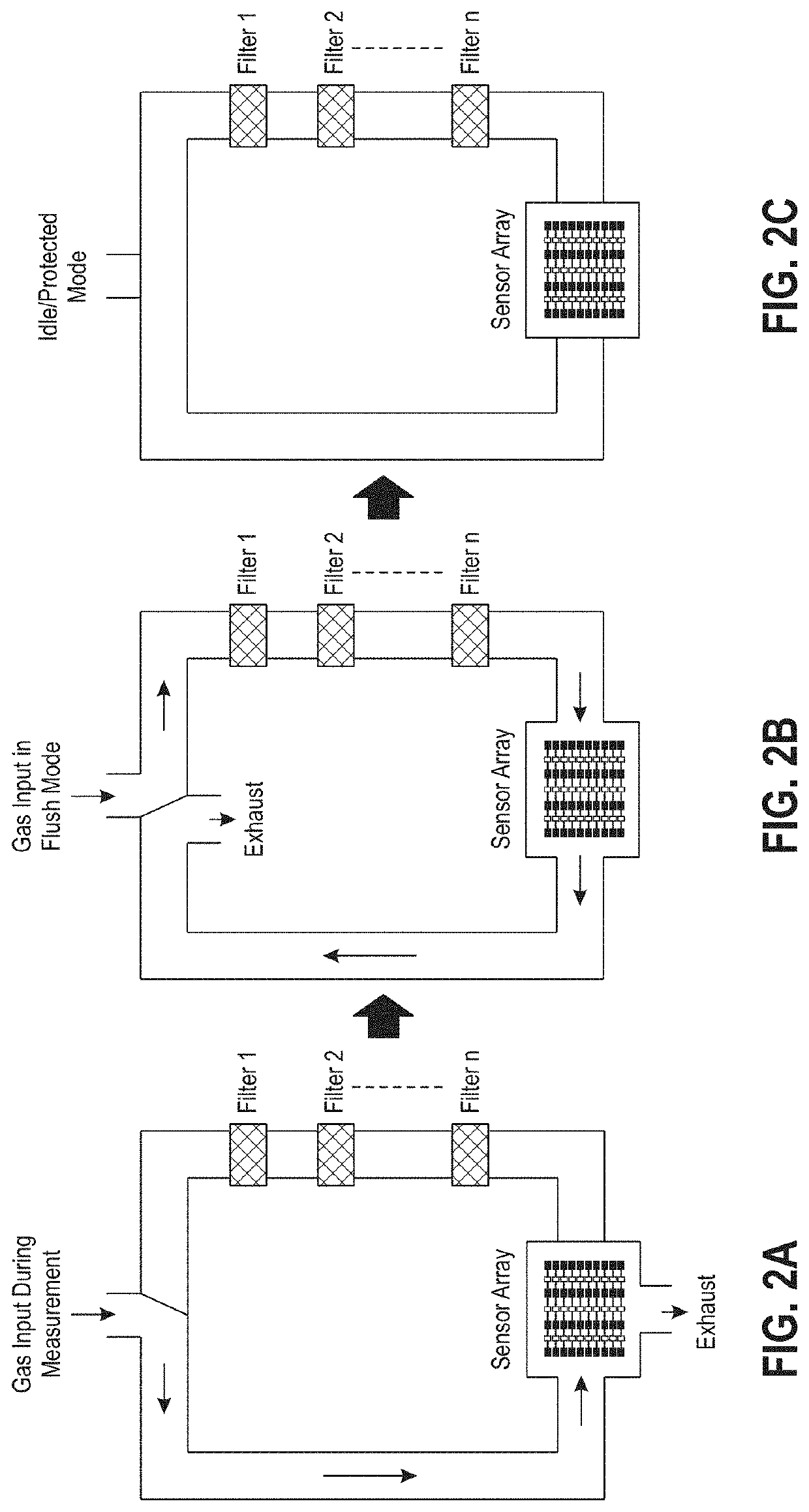

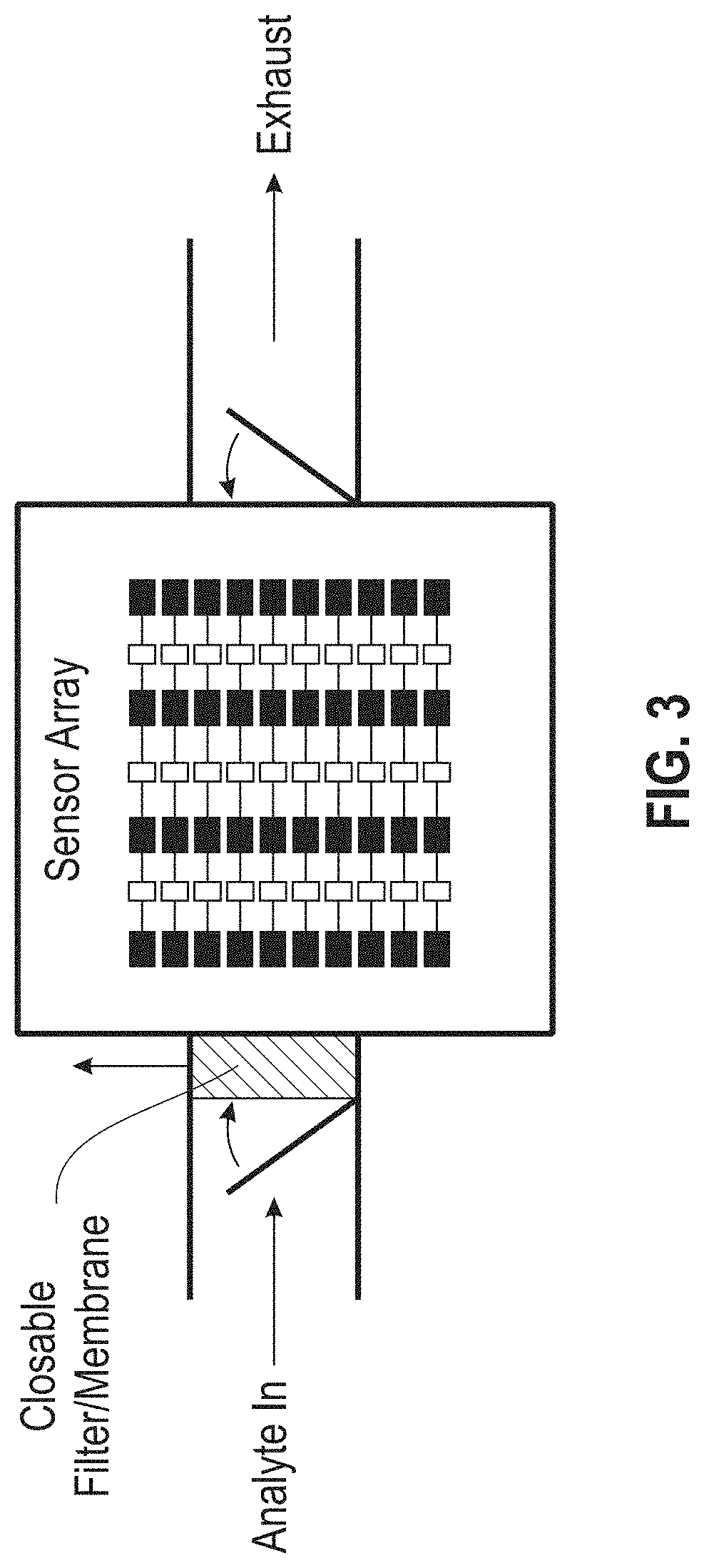

Protective enclosure for gas sensors

A small-sized, portable enclosure protects a gas sensor against degradation due to environmental exposure and changes in atmospheric conditions. The protective enclosure includes an inlet for introduction of a gas into the enclosure, an outlet for release of the gas upon completion of a sensing run, and a number of in-line filters that remove from the inflowing gas sample analytes, contaminants, and other materials that can compromise the integrity of the sensor or cause the sensor to degrade over time. The enclosure does not include any filters during the measurement phase of the sensing run in order to allow the gas sensor to accurately measure an unmodified gas mixture and / or analyte.

Owner:TECH UNIV EINDHOVEN +2

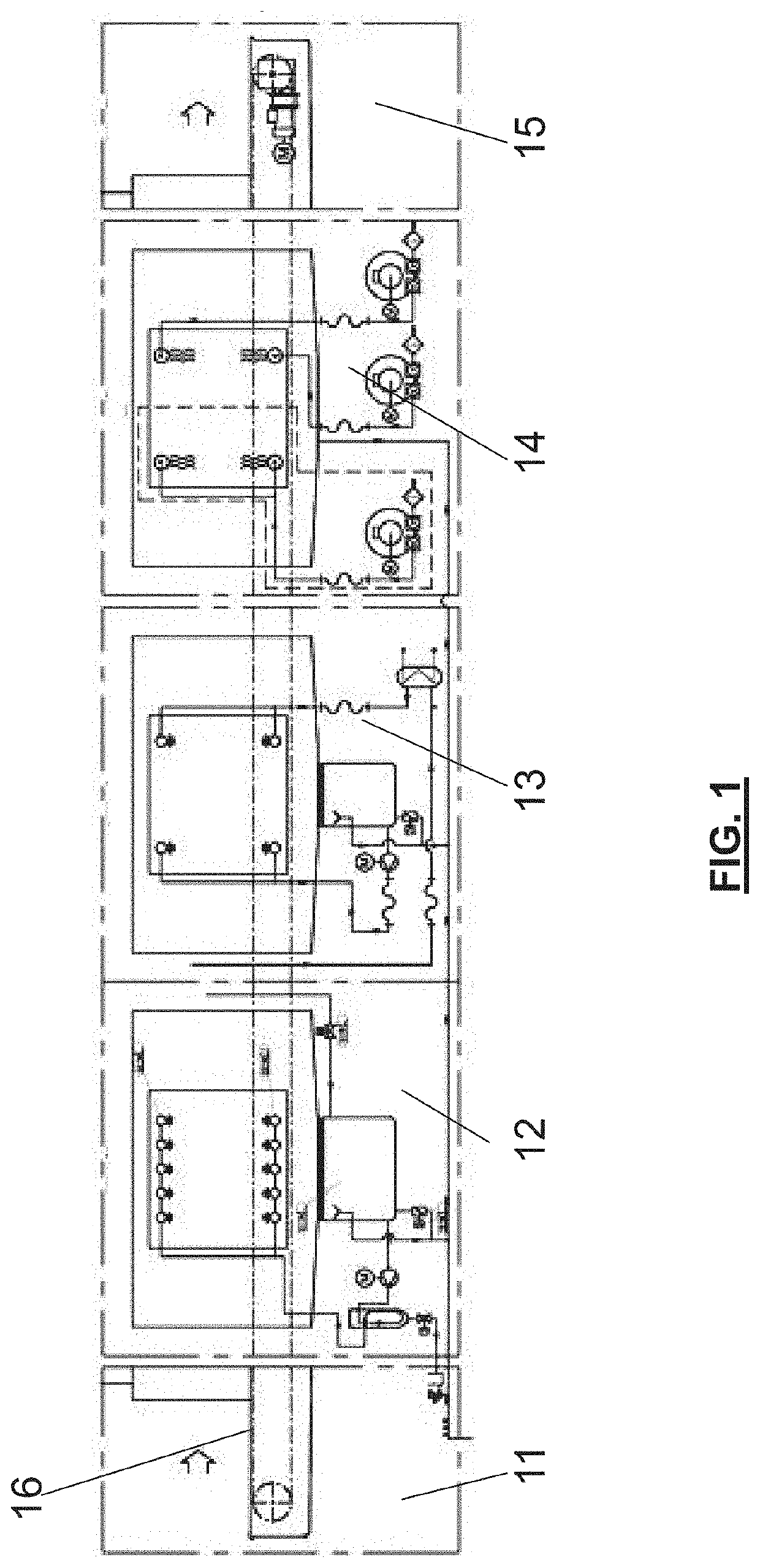

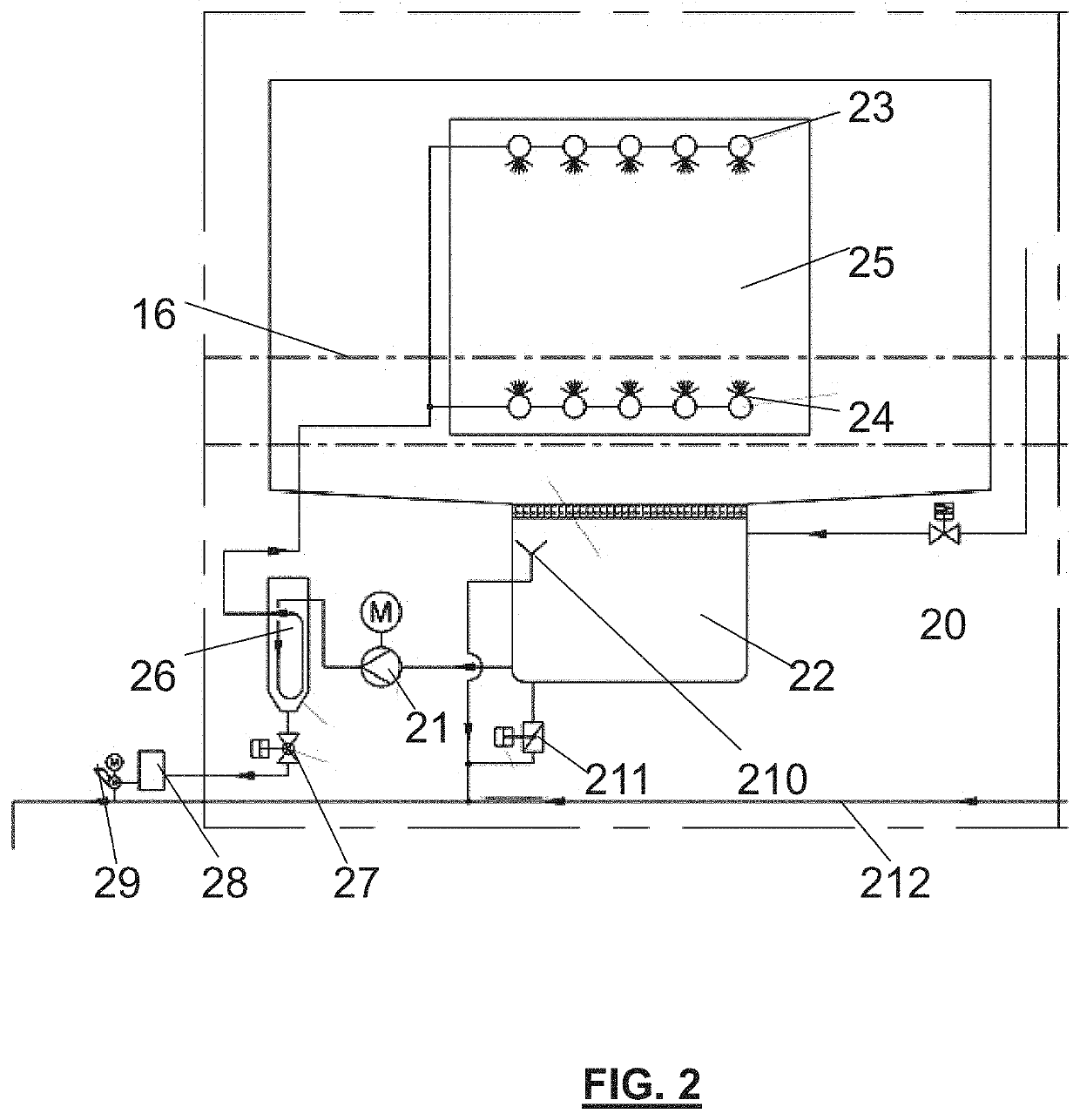

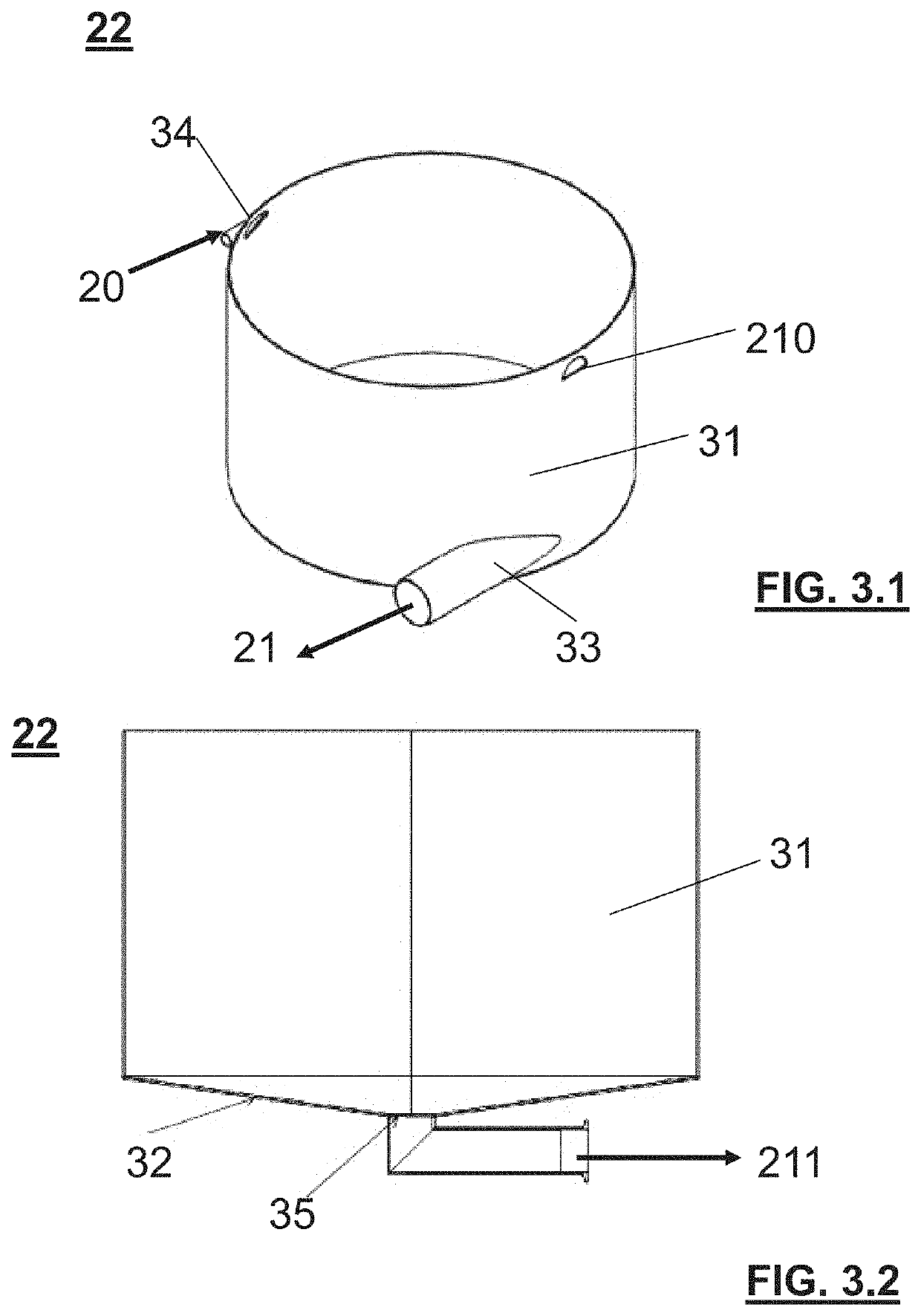

System for treating wash waste liquid, adapted for application in a continuous tunnel washing machine in the field of preclinical pharmaceutical research

A system for treating wash waste liquid is described, configured for coupling to a wash module of a continuous Tunnel washing machine for the field of Preclinical Pharmaceutical Research, said wash module (12) comprising a wash chamber (25), characterized in that it comprises:a wash tub (22) with a side wall (31) substantially cylindrical in shape, with a tangential liquid suction outlet (33) and a substantially conical bottom, with a wash waste drain point (35) at the vertex of the cone, said tangential suction being adapted to generate a rotational motion of the liquid in said tub, said tub being positioned under said wash chamber (25), so as to receive said wash liquid by gravity;a centrifugal wash pump (21) with an open impeller, adapted to take in liquid from said tangential liquid suction outlet (33);an in-line filter (26) with an internal filter cartridge of the “wedge-wire” type, adapted to filter the liquid coming from said centrifugal pump (21) and deliver it back, filtered, into said wash chamber (25), and comprising a flush valve (27) for discharging the filtering waste.

Owner:IWT SRL

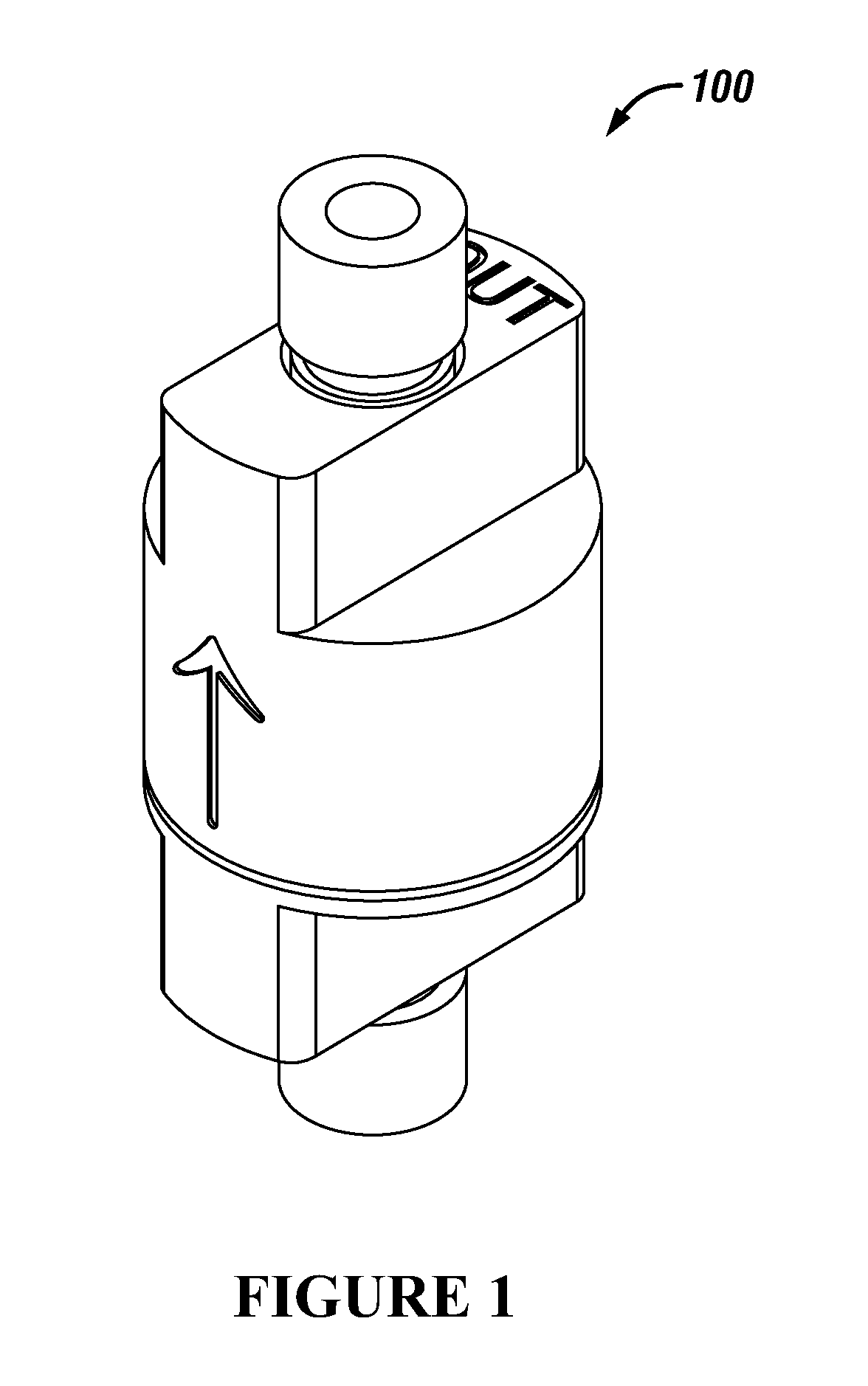

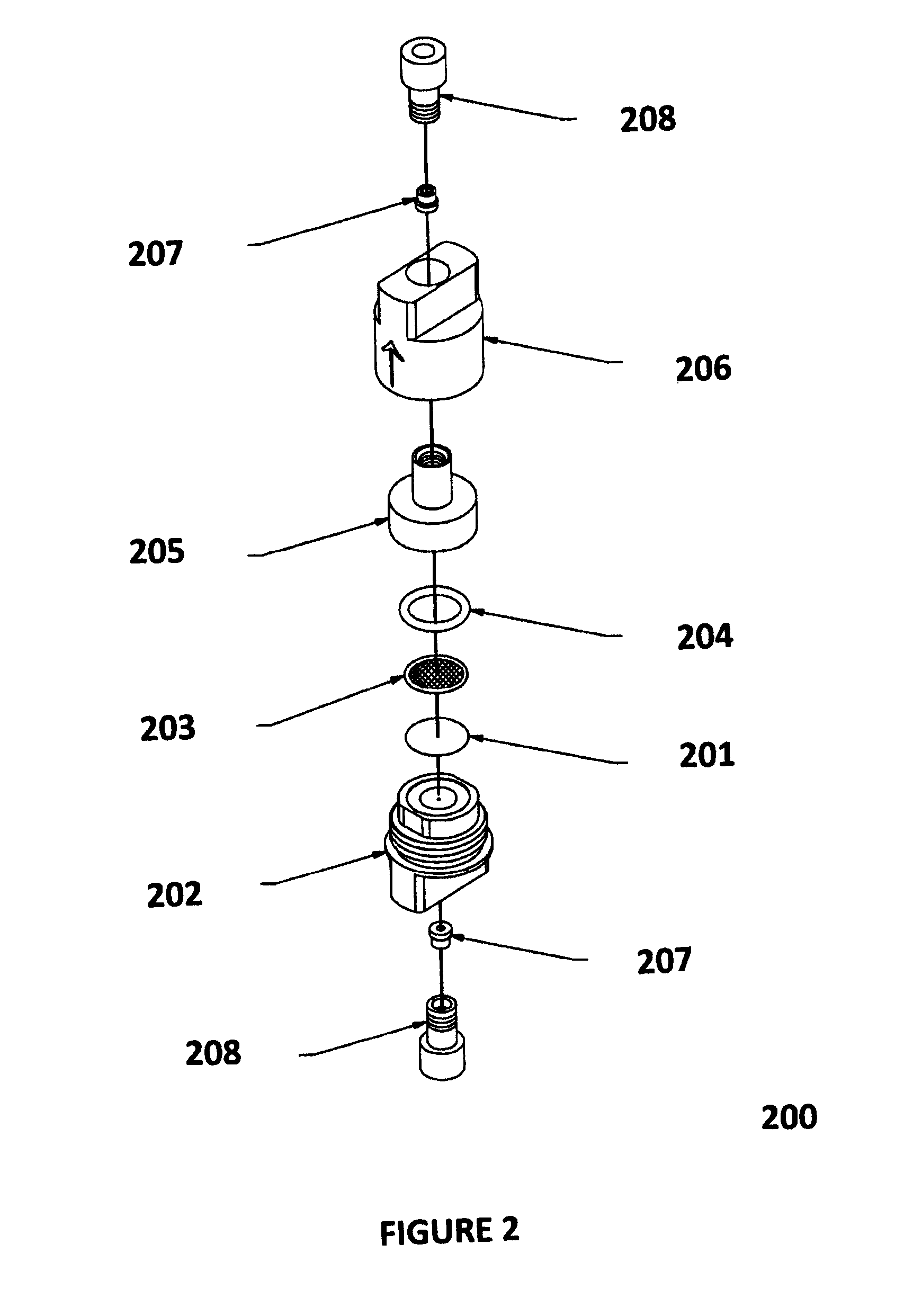

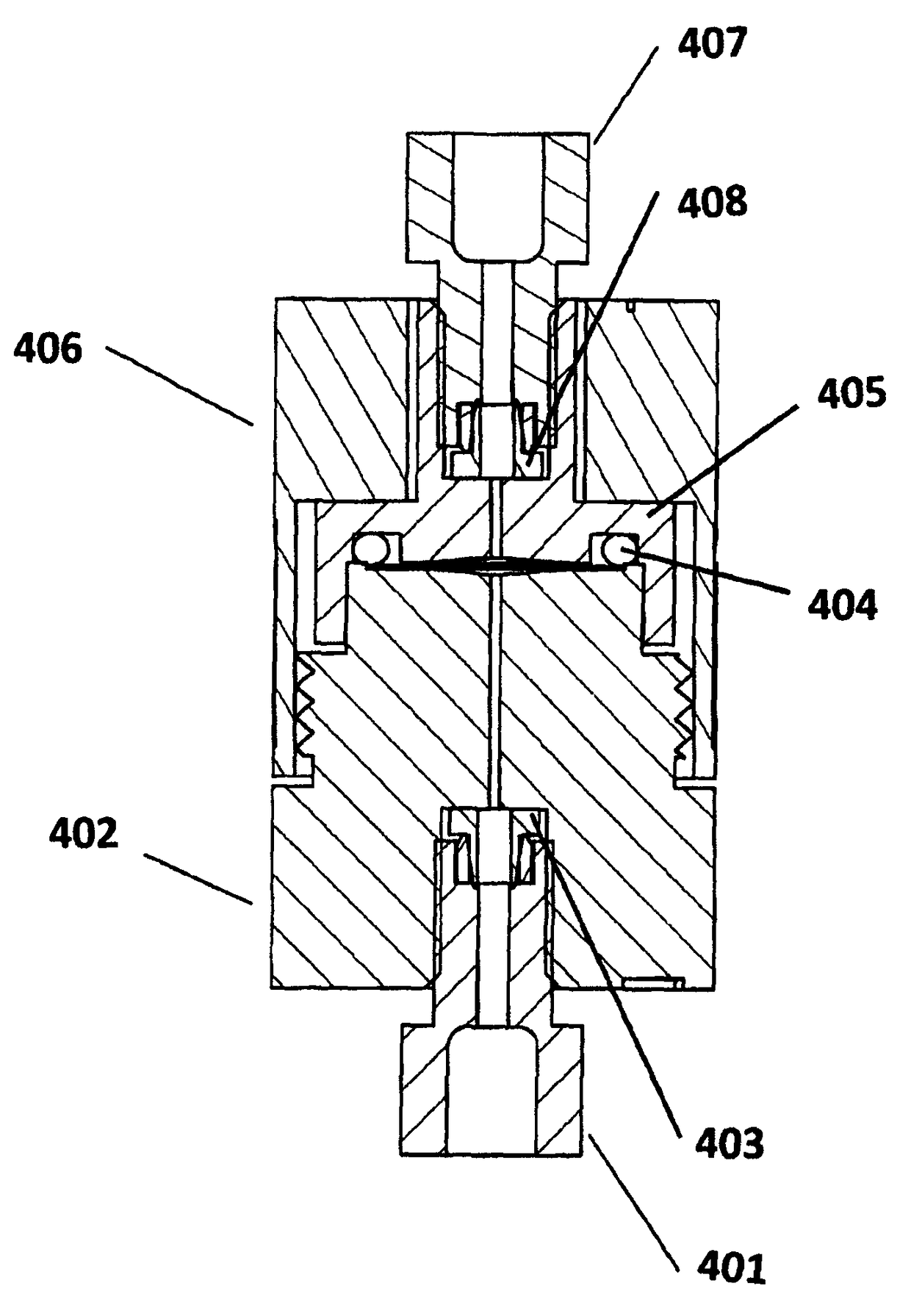

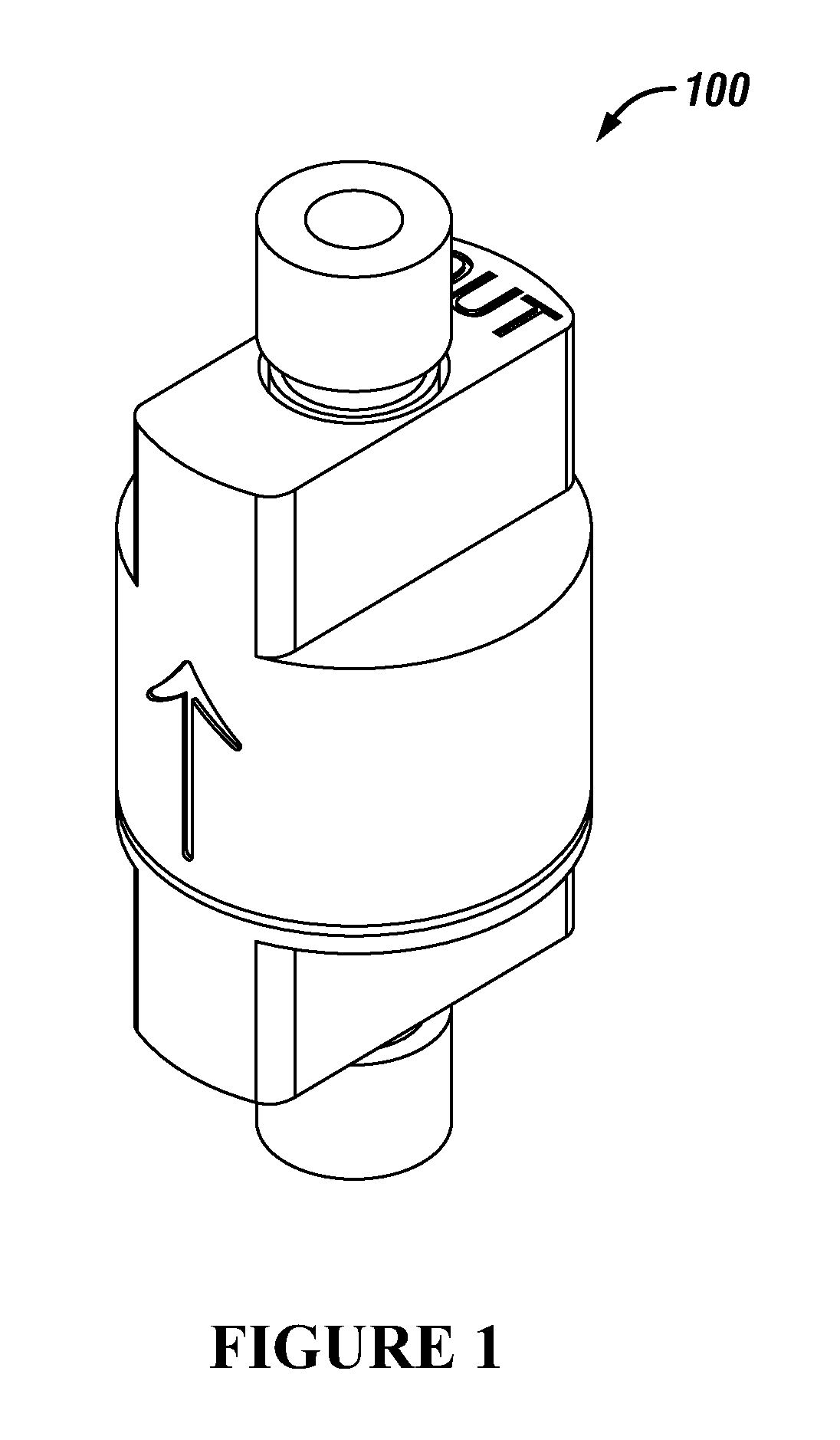

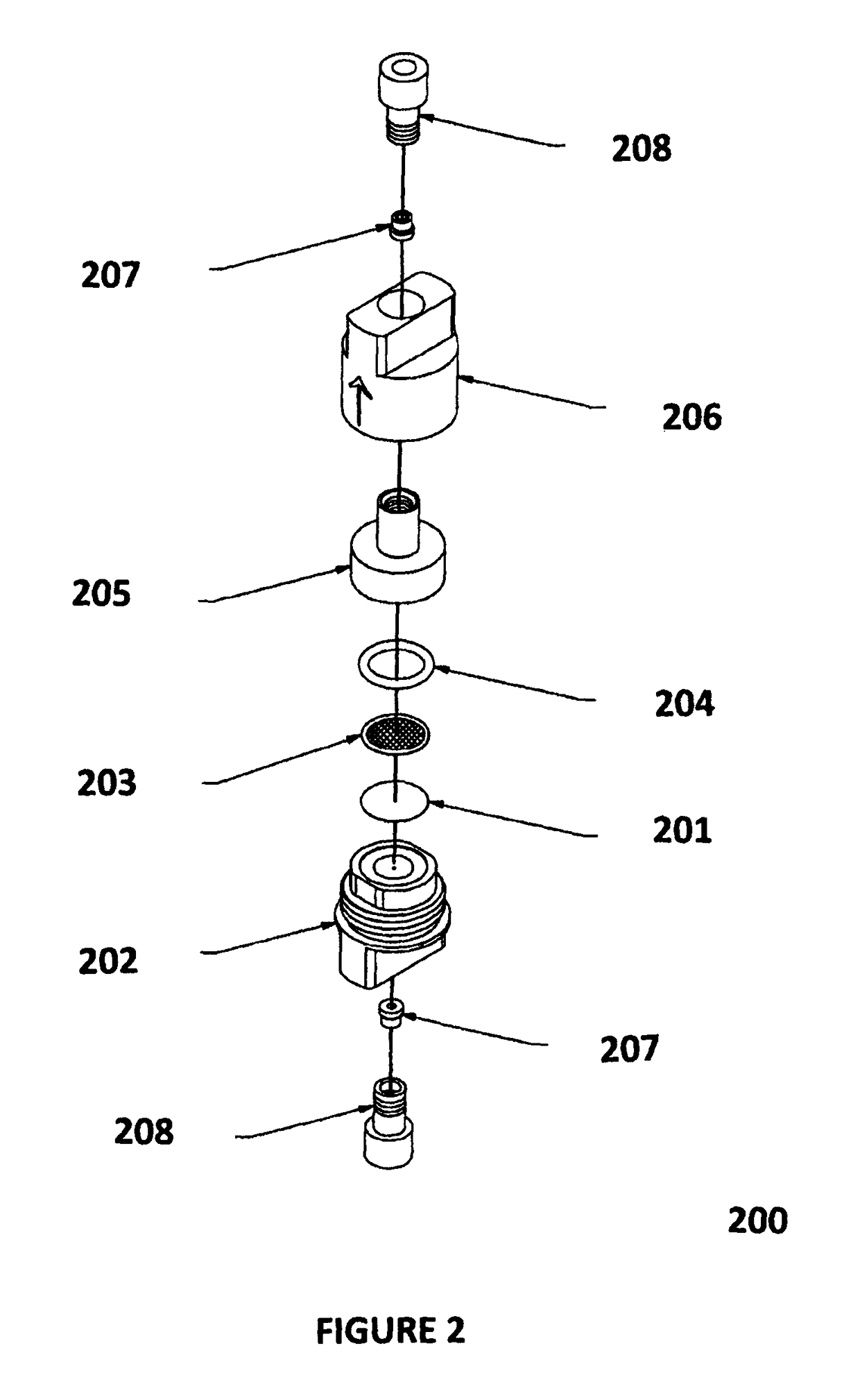

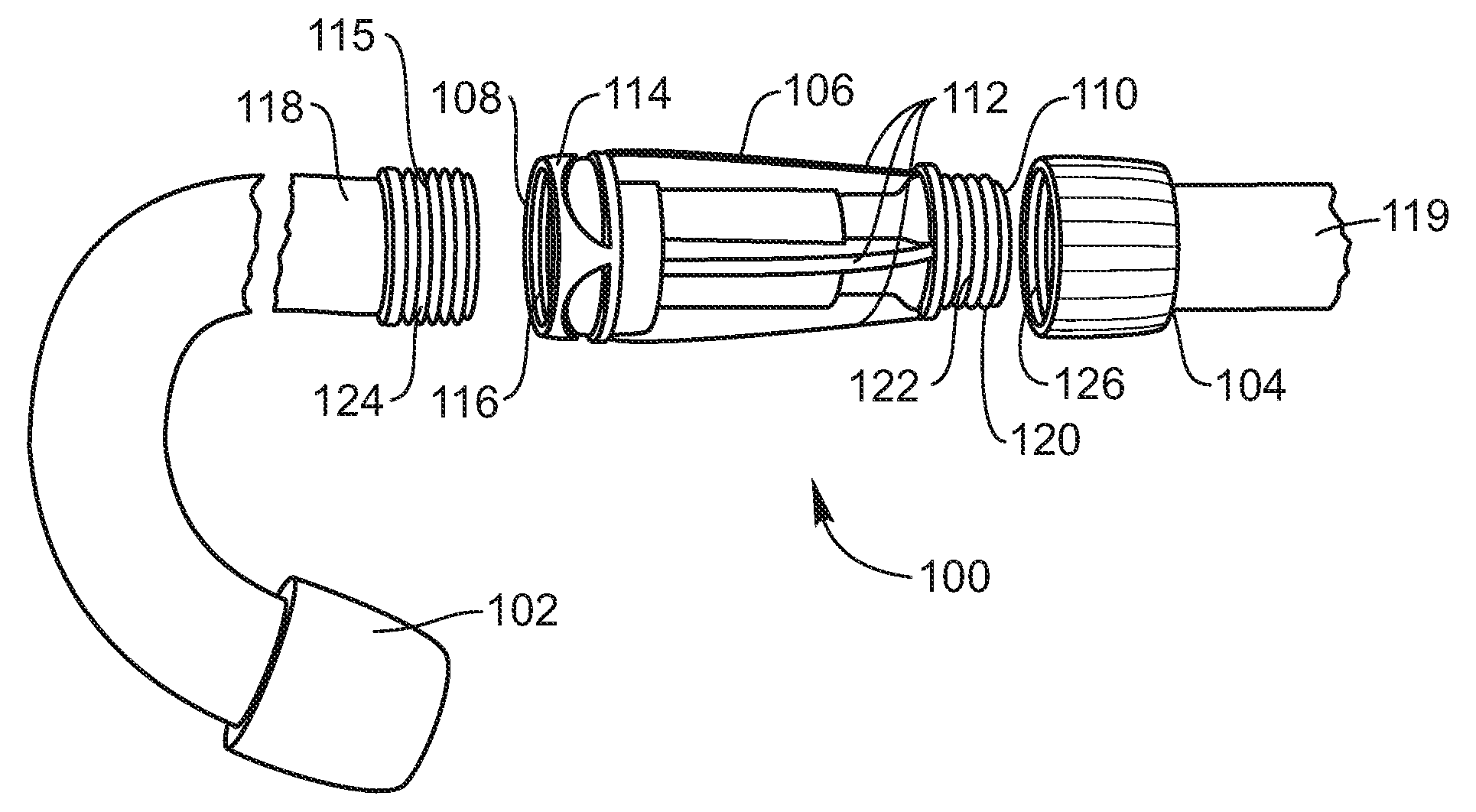

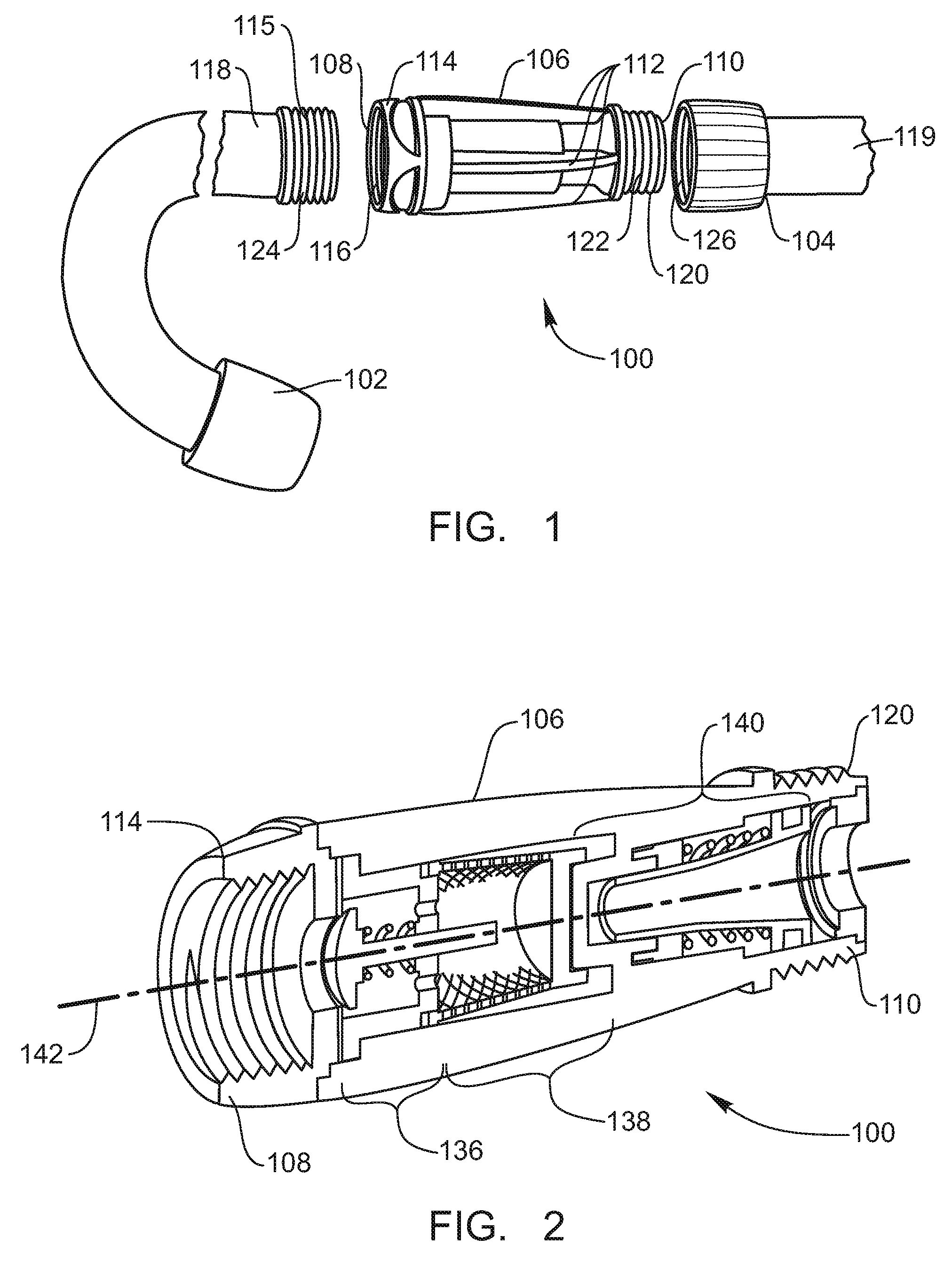

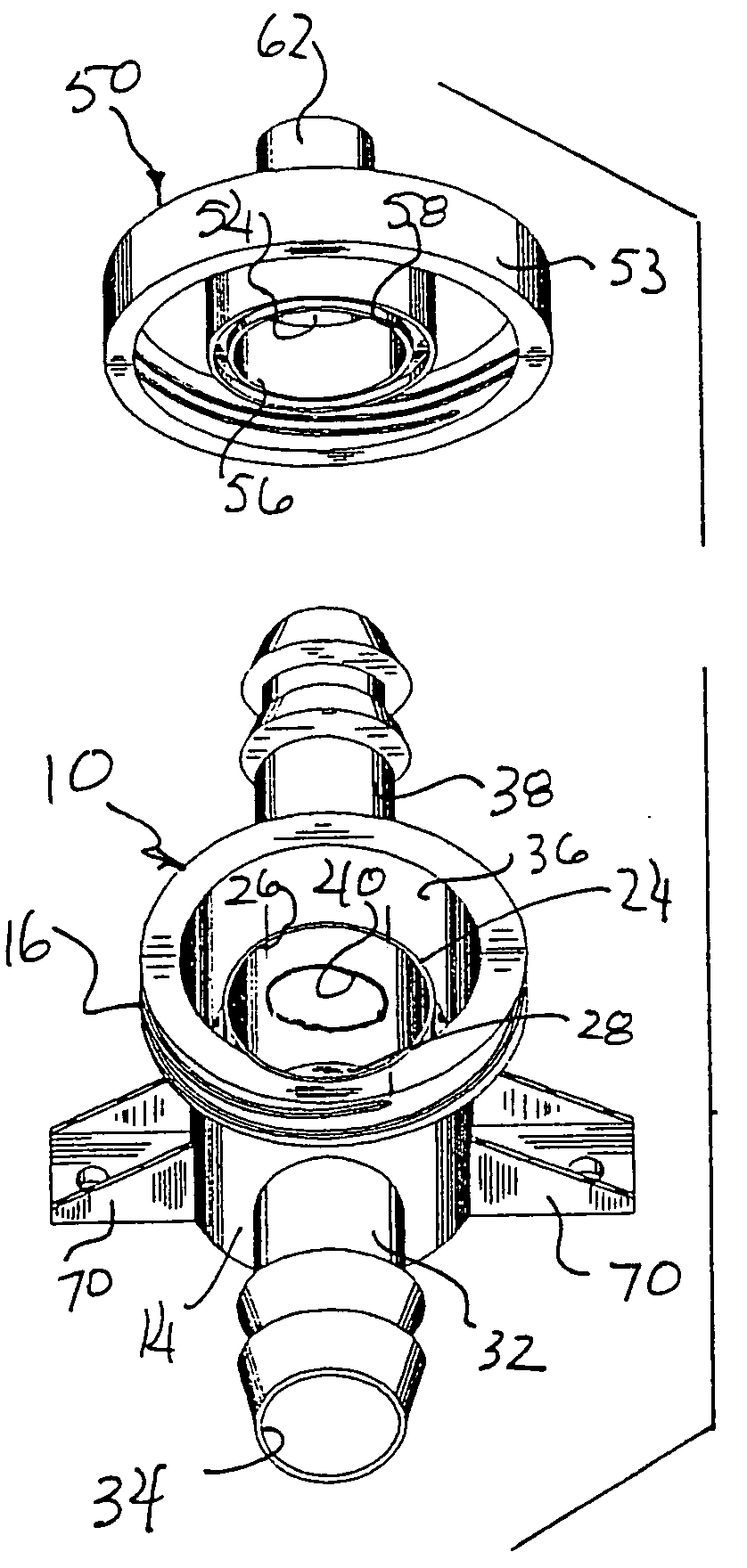

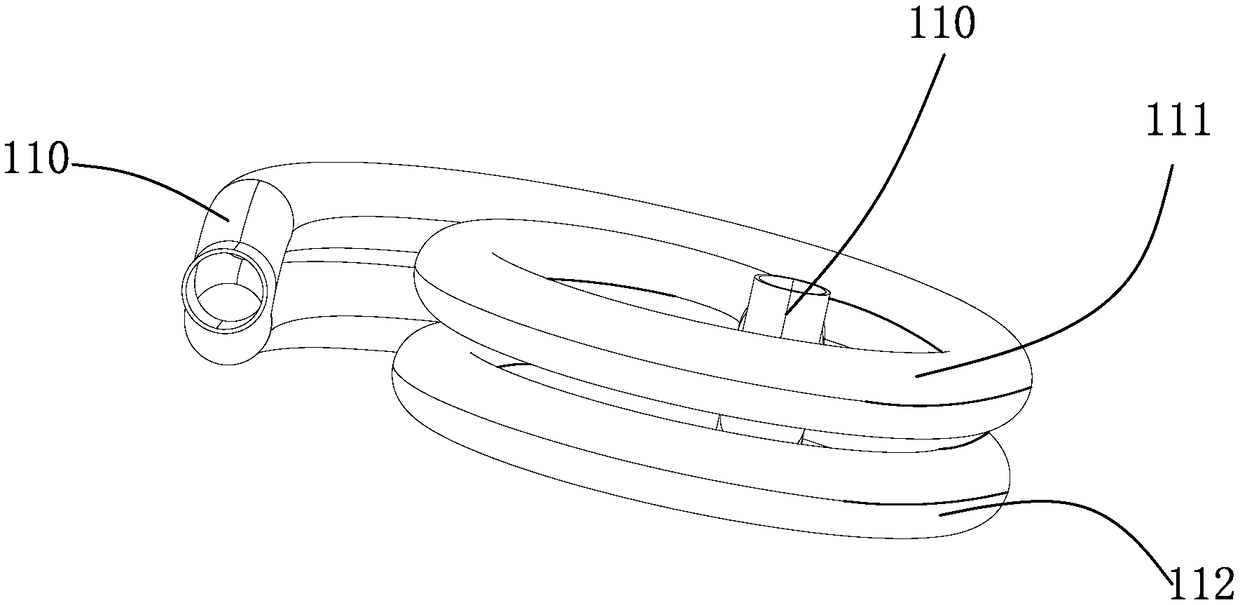

In-line filter/flow regulator/Anti-siphon device

InactiveUS20090229675A1Decreasing fluid flowReduce pressureCheck valvesDomestic plumbingSiphonIn line filtration

An in-line, hose-end filter / flow regulator / anti-siphon device is disclosed. The disclosed hose-end device includes a unitary body having a generally linear side profile, a first end, a second end, and a longitudinal axis. An inlet hose-end receptor is disposed on the first end, while an outlet hose-end receptor is disposed on the second end. An anti-siphon section, a filter section, and a flow regulator section are positioned between the first end and the second end. The inlet hose-end receptor, the anti-siphon section, the filter section, the flow regulator section, and the outlet hose-end receptor are coaxial with the longitudinal axis of the body.

Owner:ORBIT IRRIGATION PRODS

Magnetic inline filter

ActiveUS20150165447A1Simple structureStrong fermentation abilityWater/sewage treatment by magnetic/electric fieldsFiltration separationEngineeringIn line filtration

A magnetic inline filter is provided. A piston rod of a fluid cylinder is retracted to the top to locate an inner circumferential surface side magnet and an outer circumferential surface side magnet in filtration positions opposed to a space. In this state, a solenoid of a changeover valve is actuated to shut off a discharge port. A coolant is introduced into the space from an introduction port in the vicinity of the lower end of an outer pipe. Since a magnetic field in a radiation direction is intense, chips in the coolant are attracted to wall surfaces on both sides of the space and the coolant is filtrated. When the supply of the coolant is continued, the chips attracted to the wall surfaces are accumulated and bridged. As a result, since the coolant passes through gaps of the bridged chips, it is possible to perform precise filtration.

Owner:SHOUNAN ENG

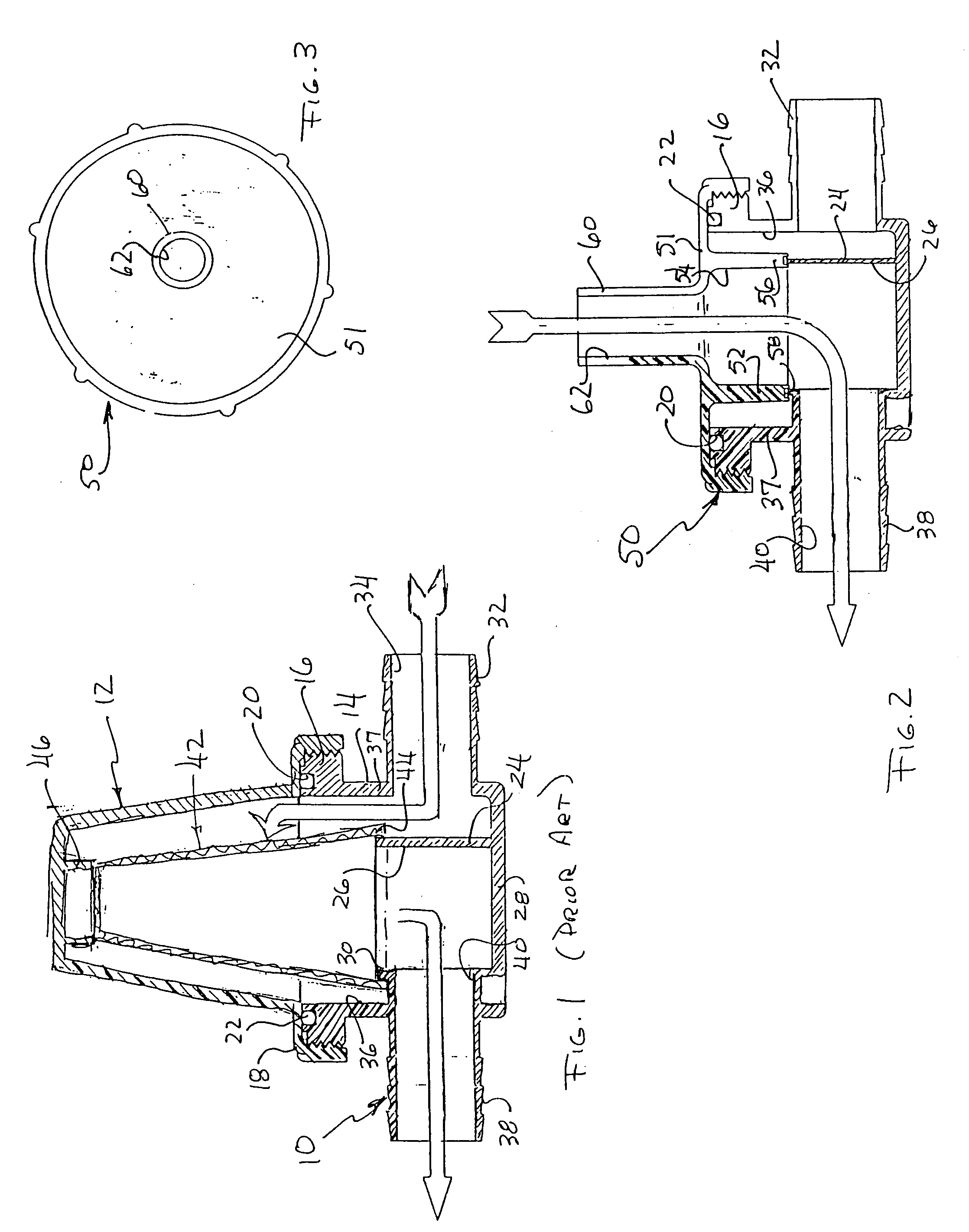

Flushing adapter for filter

InactiveUS20060000765A1Quickly and easily attachedPipe elementsLoose filtering material filtersIn line filtrationBiomedical engineering

In the method, an adapter is substituted for the filter-enclosing cap of a conventional in-line strainer device to permit introduction into a plumbing system of a flushing solution withdrawn from an independent supply. The method is typically used for introducing antifreeze into the system for winterization purposes.

Owner:COLLIER DONALD G

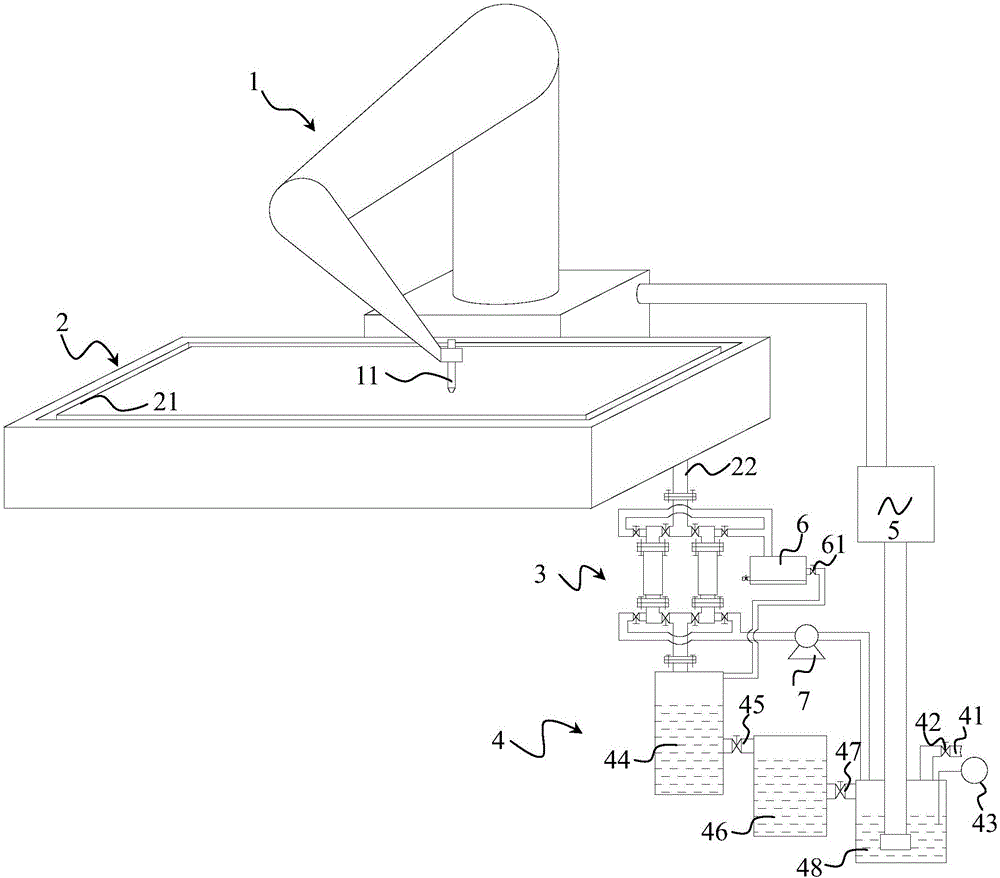

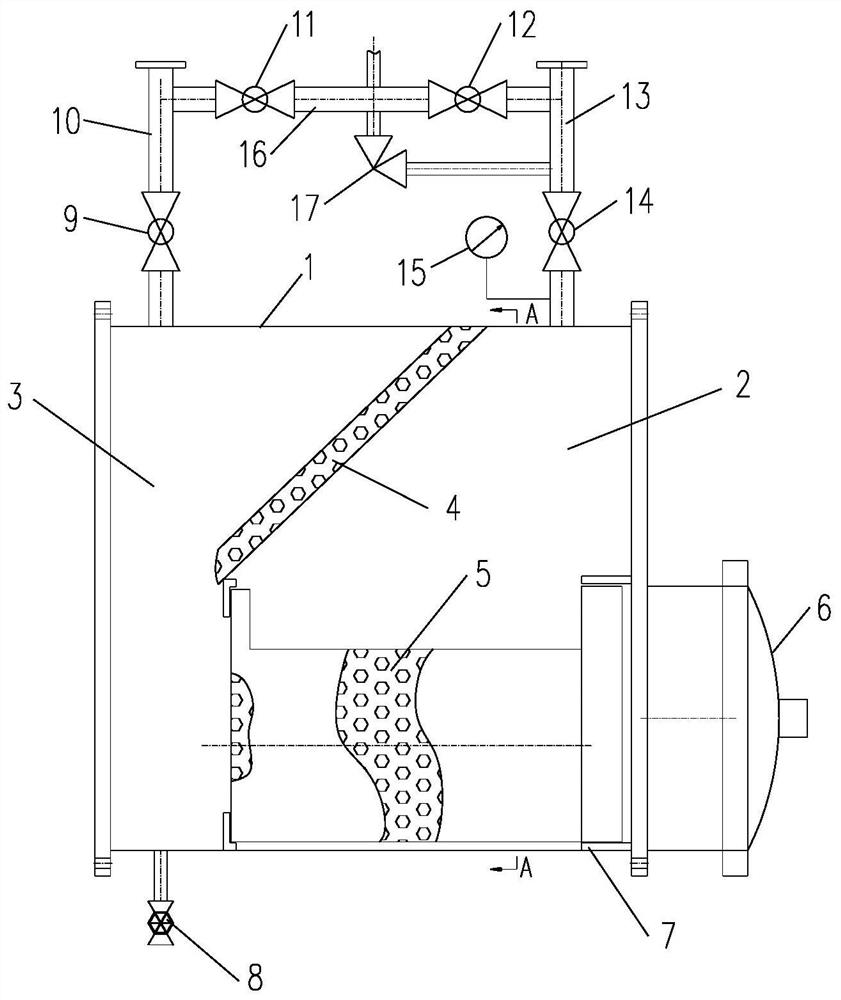

Water cutting machine tool and filtering method

ActiveCN106563849AGuaranteed cost of useReduce use costTreatment involving filtrationMultistage water/sewage treatmentWater storage tankSpray nozzle

The present invention discloses a water cutting machine tool and a filtering method. The water cutting machine tool comprises a mechanical arm, a cutting platform, a filtering device, a water storage tank, a high-pressure pump and a backwashing pool; the filtering device is provided with two branch systems; when the filtering device is applied to online filtering, filtering portions can be replaced; the water storage tank is filtered level by level through a collection tank, a mitigation tank and a clear water tank; the high-pressure pump is used for generating high-pressure water which can be used by a nozzle on the mechanical arm; the mechanical arm is connected with a control unit; the nozzle on the mechanical arm operates on the cutting platform; the filtering device is arranged between the water outlet of the cutting platform and the water storage tank; the high-pressure pump is arranged between the water storage tank and the mechanical arm; the filtering device is connected with the backwashing pool; and a submerged pump is arranged between the filtering device and the clear water tank. With the water cutting machine tool and the filtering method adopted, on-line reverse cleaning of the filtering portions of the single branch systems can be realized, and the service lives of the filtering portions can be prolonged, and the use costs of the filtering portions can be decreased, and the cost control of the water cutting machine can be optimized.

Owner:JIAXING JINXILAI TECH CO LTD

Lubricating oil filter system of wind power gear box

InactiveCN109163081AImprove purification rateSolve stressGear lubrication/coolingEngineeringHigh pressure

The invention relates to a lubricating oil filter system of a wind power gear box. The filter system is provided with an oil inlet and an oil outlet in butt joint with a gear box, a main pipe connected between the oil inlet and the oil outlet, a circulating pump arranged on the main pipe, and a filter mechanism arranged on the main pipe; the filter mechanism comprises a mechanical filter with a multistage filter screen, and a charging unit for separation of the lubricating oil and positive and negative charging of particles in two parts of the lubricating oil after separation; and the chargingunit is positioned at the upstream of the mechanical filter, and communicates with the mechanical filter through a gathering pipe. The lubricating oil filter system of the wind power gear box greatlyincreases the purifying rate of fine particles of submicron order and below 5 microns, solves online filter problems of high viscosity, high pressure and high flow, is lower on requirement of the water content in the oil, and is compact and reasonable in structural design, low in production cost and lower in maintenance cost.

Owner:CGNPC INSPECTION TECH +3

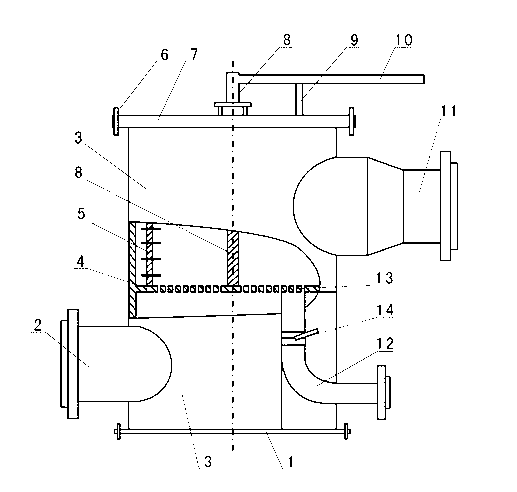

Pipeline online filter with function of manual sewage discharge

The invention discloses a pipeline online filter with a function of manual sewage discharge. According to the pipeline online filter, a housing cylinder is provided with a material inlet and a material outlet, the material inlet is arranged on the lower section of the housing cylinder, the material outlet is arranged on the upper section of the housing cylinder, a filtration screen cylinder is arranged inside the housing cylinder and on the upper section inside the housing cylinder, and comprises a center shaft fixedly connected with the filtration screen cylinder body, the upper end of the center shaft penetrates through the housing cylinder, and is connected with a rotation handle, a separation plate is arranged below the filtration screen cylinder, the separation plate region positioned inside the filtration screen cylinder is provided with a plurality of small holes communicated from top to bottom, a position of the separation plate lower surface positioned below the cylinder wall of the filtration screen cylinder is connected with a sewage discharge pipe, and the sewage discharge pipe is provided with a manual valve. During operation, when filtration residues on the filtration screen cylinder are too much, the rotation handle rotates so as to rotate the filtration screen cylinder at a slow speed, the manual valve on the sewage discharge pipe is opened, a filtration process is not affected, and continuous online filtration is achieved.

Owner:CHENGDU SIMAO TECH

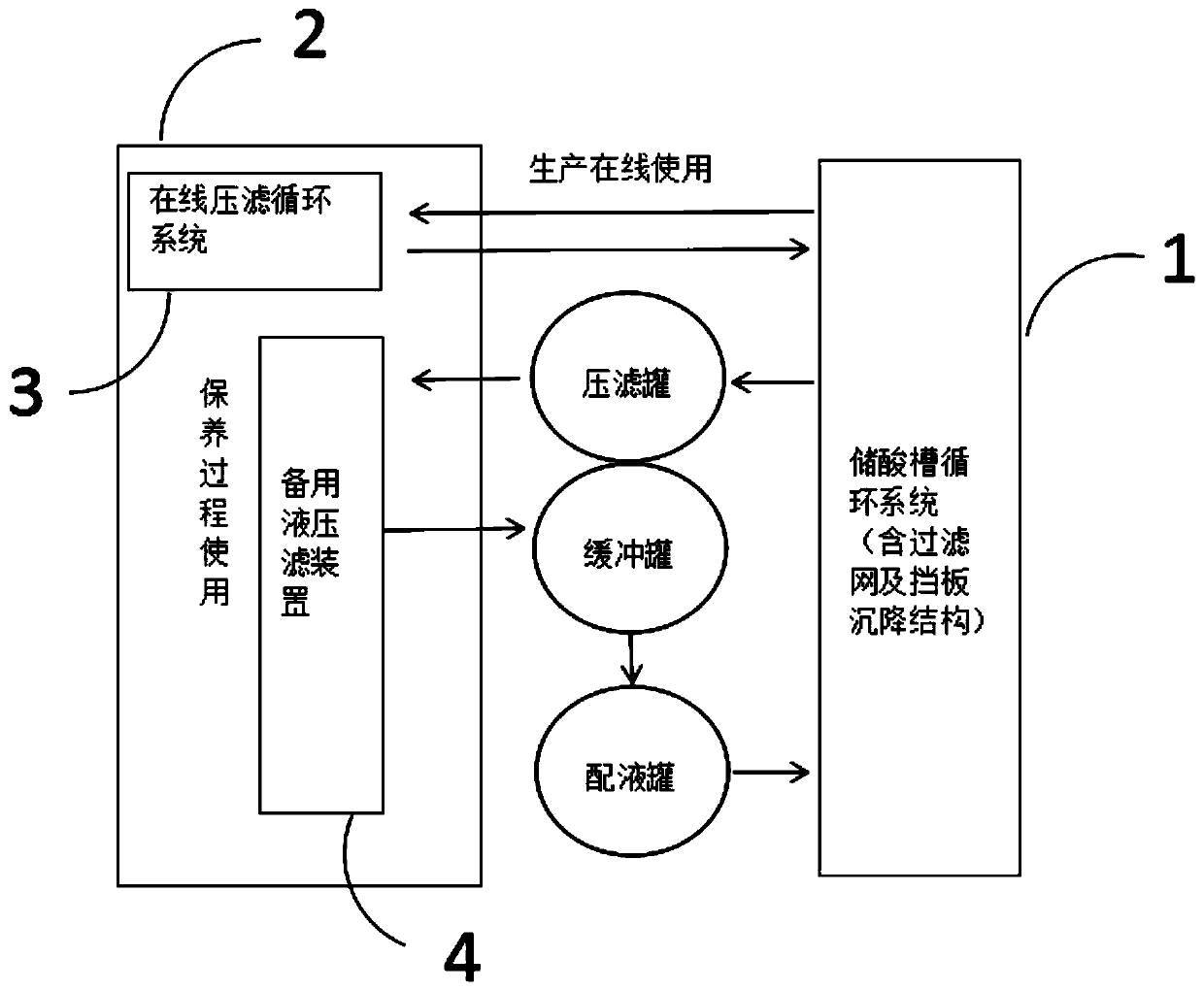

An online filtration circulation system and method for etching solution containing glass powder

The invention belongs to the technical field of liquid crystal display panel etching, and discloses a glass powder-containing etching solution on-line filtering circulating system and a method. The glass powder-containing etching solution on-line filtering circulating system is provided with a press filtration system; the press filtration system comprises an online press filtration circulating system, and two standby liquid press filtration devices; the online press filtration circulating system is arranged at the bottom of an acid storage tank, is tapered, and is used for on-line continuous clearing of waste residue accumulated at a cone bottom via continuous passing through of a press filter; the two standby liquid press filtration devices are used for alternative circulating applications in filtration of waste residue-containing etching solution. According to the glass powder-containing etching solution on-line filtering circulating system, filtering and settlement are adopted, waste residue removing is carried out as far as possible in production process, accumulation of waste residue in etching solution is reduced, etching solution using cycle is prolonged; reduction of wasteresidue accumulation is also realized via on-line press filtration; the two standby liquid press filtration devices are adopted, removing of waste residue through press filtration of standby liquid isrealized; the above design is capable of realizing etching solution purification as far as possible, and ensuring production quality and batch production continuity.

Owner:UNITECH OPTRONICS TECH HUBEI

Collecting and filtering device for removing impurities from submarine pipeline

PendingCN112957813ASolve problems such as blockage and pressure suppressionImprove delivery efficiencyFiltration circuitsMarine engineeringIn line filtration

The invention discloses a collecting and filtering device for removing impurities from a submarine pipeline, which comprises a barrel, an inner cavity of the barrel is composed of a front filtering chamber and a rear filtering chamber, the front filtering chamber is provided with an inlet part and a collecting and filtering part, the collecting and filtering part is provided with a drawer type filter screen, an outlet is arranged on the side wall of the barrel, a barrel door is mounted on the outlet, an upper opening of the drawer type filter screen is in butt joint with a bottom opening of the inlet part, and a partition plate type filter screen is arranged between the inlet part and the filtering rear chamber; the rear filtering chamber is arranged on the periphery of the front filtering chamber, the top of the rear filtering chamber is connected with an outlet pipe, and a valve IV is arranged on the outlet pipe; and an inlet pipe is connected to the inlet part, a valve III is arranged on the inlet pipe, a communicating pipe is arranged between the inlet pipe and the outlet pipe, a valve I is arranged on the communicating pipe, and the communicating pipe is arranged on the side, away from the barrel, of the valve III and the valve IV. According to the invention, on-line filtration and collection of a large amount of impurities in the reaching process can be realized.

Owner:中海油(天津)管道工程技术有限公司

Preparation method of aluminum alloy for battery shell

The invention provides a preparation method of an aluminum alloy for a battery case, which comprises the following steps: A) burdening according to the components of the aluminum alloy, and sampling and analyzing after melting; b) adding a granular refining agent into the melt obtained in the step A) for refining to obtain a melt; c) sequentially carrying out on-line degassing, on-line filtering and on-line refining on the melt; and D) casting the melt obtained in the step C). According to the preparation method of the aluminum alloy for the battery shell, the chemical components can be controlled, the hydrogen content is smaller than or equal to 0.15 ml / 100 gAl, the grain size is 1.5 level, and the performance requirements for excellent formability, corrosion resistance, welding and the like of the battery shell are met.

Owner:SOUTHWEST ALUMINUM GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com