Water cutting machine tool and filtering method

A cutting machine tool and water cutting technology, which is applied in the direction of filtration circuit, filtration separation, filtration treatment, etc., can solve the problems of reducing the service life of the filtration device, increasing the cost of parts and components, and reducing the effective working time, so as to improve the service life and realize Effect of recycling and optimizing cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, and therefore are only examples, and should not be used to limit the scope of protection of this patent. In addition, the terms "first", "second", etc. are used for descriptive purposes only, and should not be understood as indicating or implying relative importance or implicitly specifying the quantity of the indicated technical features.

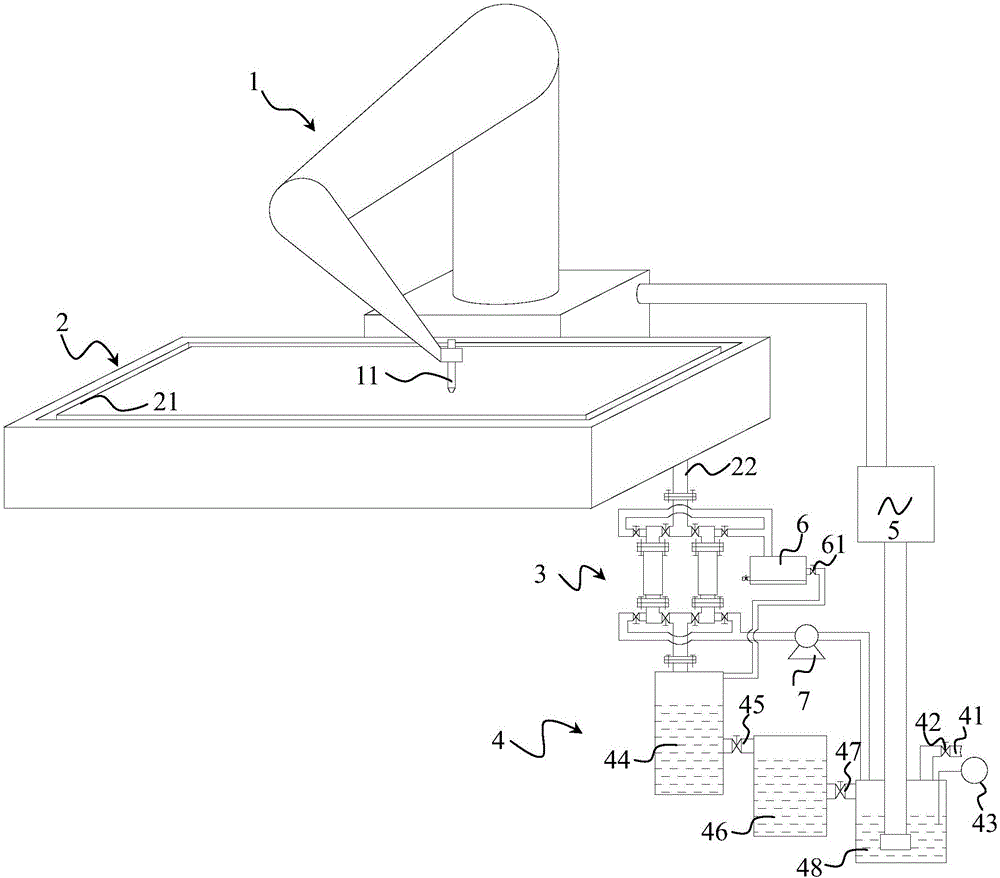

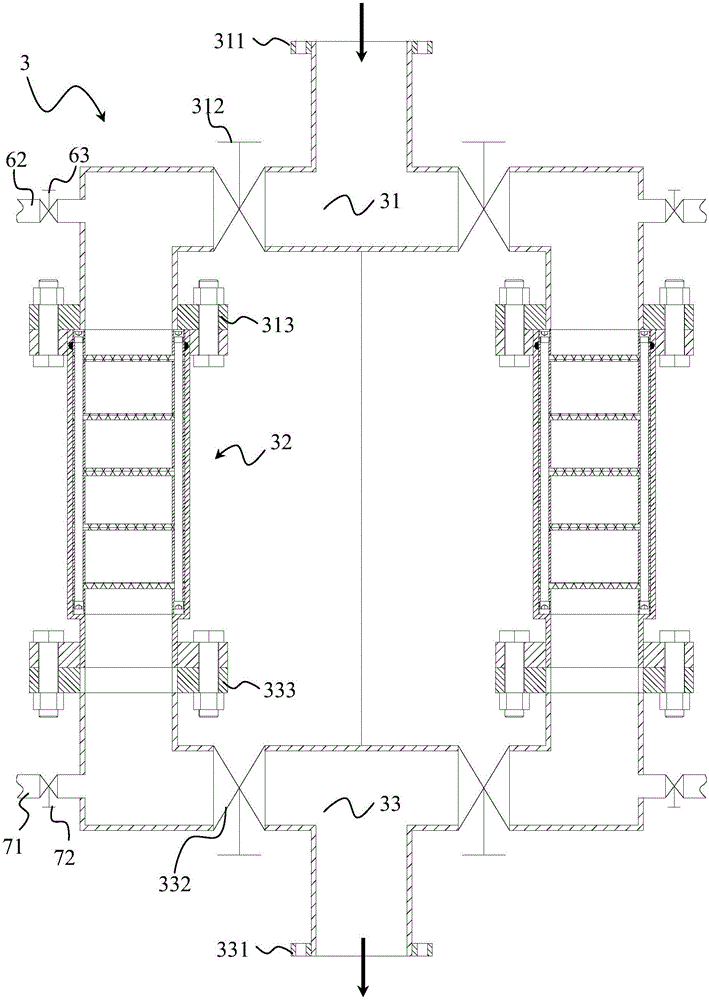

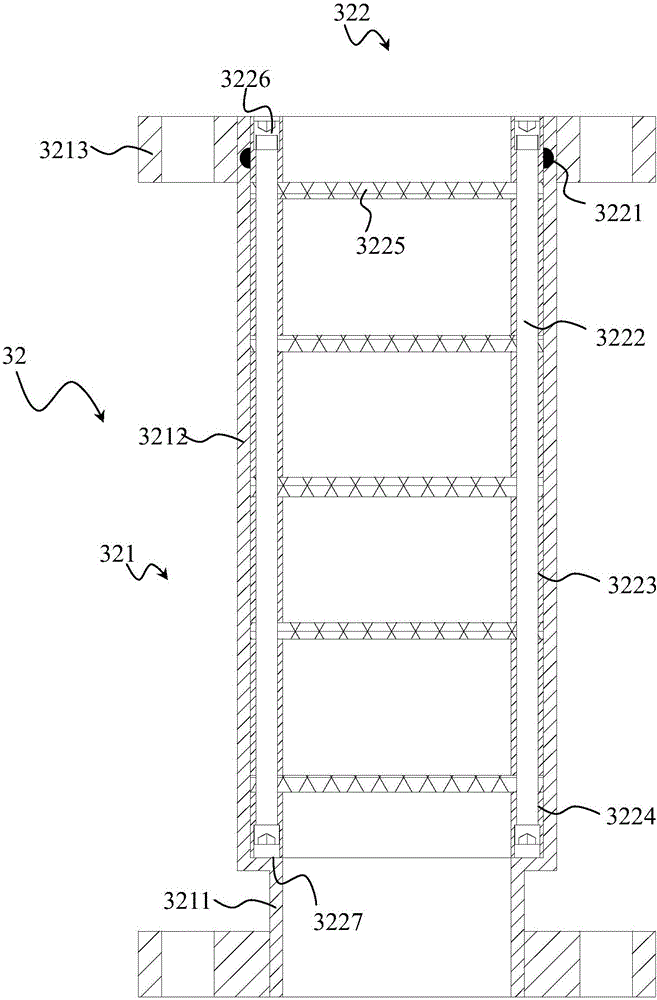

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 As shown, this embodiment discloses a water cutting machine tool, including a mechanical arm 1, a cutting platform 2, a filter device 3, a water storage tank 4, a high-pressure pump 5 and a backwashing pool 6; the mechanical arm 1 is controlled by a control unit to cut The platform 2 is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com