Abrasive cloth

A technology of abrasive cloth and transition layer, applied in the field of abrasive cloth, can solve the problems of increasing production and use costs, reducing the service life of abrasive cloth, affecting grinding efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

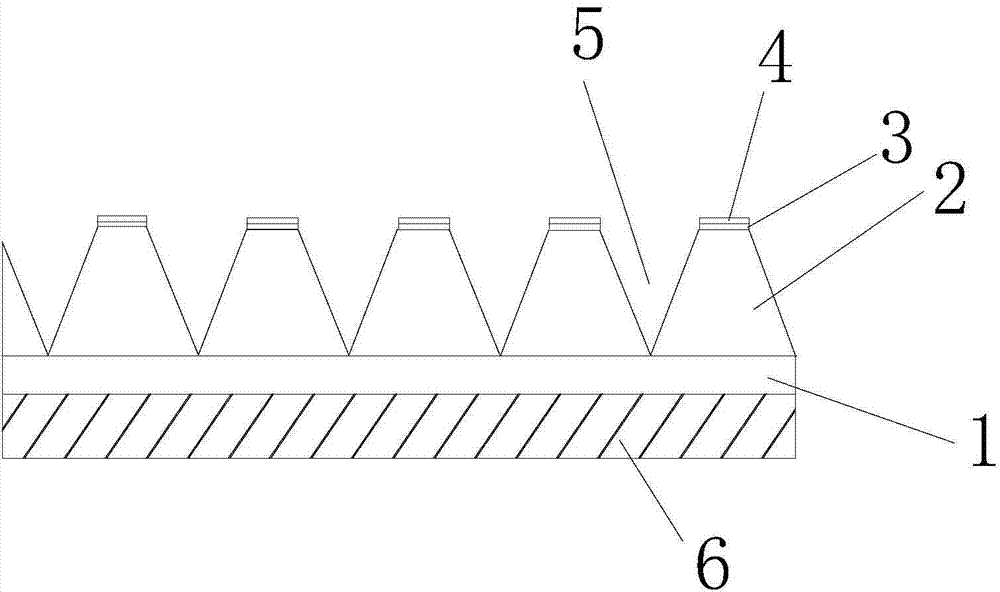

[0013] Such as figure 1 A kind of emery cloth shown comprises base material 1, transition layer 2, primer layer 3 and polishing sand 4, and described transition layer 2 is arranged on the upper surface of base material 1, and described primer layer 3 is coated on transition On the upper surface of the layer 2, the sanding sand 4 is arranged on the upper surface of the primer layer 3, and the side of the transition layer 2 has a trapezoidal zigzag structure.

[0014] The upper part of the transition layer 2 has a terrace, and the primer layer 3 is evenly coated on the terrace, and a chip removal groove 5 is formed in the lower part of the transition layer 2 .

[0015] A layer of polyether sponge 6 is provided on the bottom surface of the substrate 1 .

[0016] The primer layer 3 is a polyurethane layer.

[0017] The present invention has a simple structure, and because the transition layer has a step, the sand does not need to cover the entire base material, which saves a lot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com