Combined flue gas cleaning system and flue gas cleaning method thereof

A flue gas purification system and combined technology, applied in the direction of chemical instruments and methods, combined devices, separation methods, etc., can solve the problems of ineffective removal of acid gas and solid dust, increase of spray tower diameter and volume, Increased investment costs and other issues, to achieve the effect of reducing wastewater discharge, reducing equipment investment, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

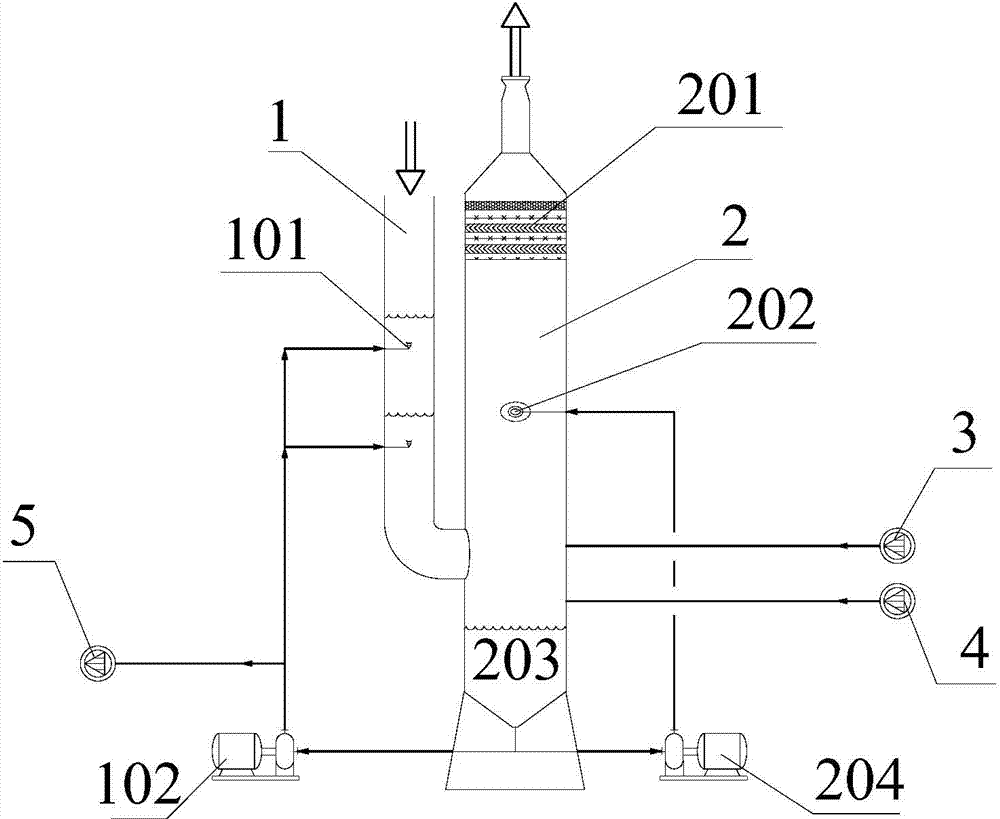

[0039] In order to more clearly illustrate the technical solutions in the embodiments of the present invention or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. Those skilled in the art can also obtain other drawings based on these drawings without creative work.

[0040] The combined flue gas purification system of the present invention is composed of a countercurrent injection pipe and a spray washing tower. The flue gas enters the straight barrel type counter-current injection pipe from top to bottom, and the counter-current spray layer sprays the absorption liquid from bottom to top. The gas-liquid two-phase reversely collides in the counter-current injection tube, and a foam zone is formed in the counter-current injection tube due to the principle of ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com