Flue gas desulfurization and denitrification equipment of sintering machine

A desulfurization and denitrification, sintering machine technology, applied in the direction of lighting and heating equipment, waste heat treatment, furnace, etc., can solve the problems of high concentration of heavy metals, environmental pollution, non-applicable, etc., achieve high denitrification efficiency, reduce initial investment, and prolong life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

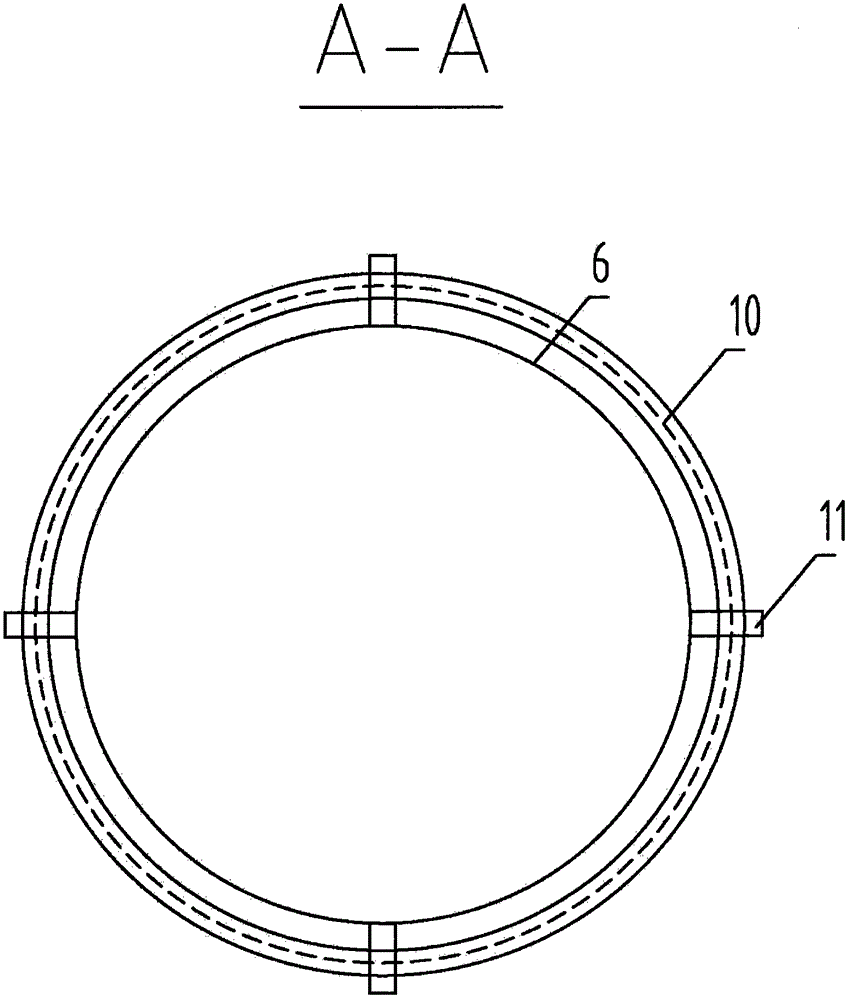

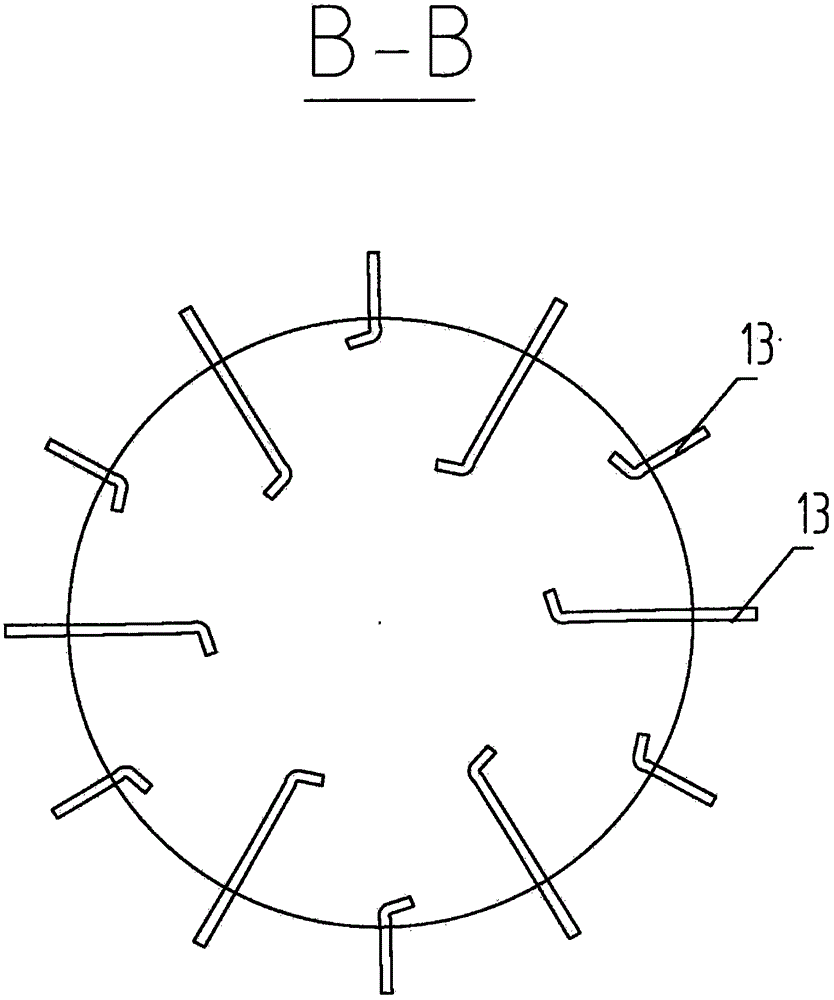

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

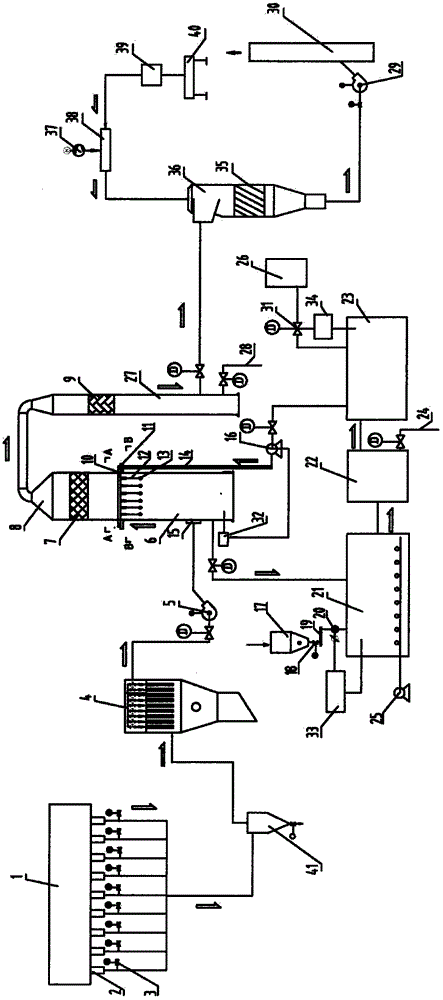

[0025] like figure 1 , figure 2 , image 3 As shown, the present invention is a sintering machine flue gas desulfurization and denitrification equipment, including a sintering machine 1, a bellows 2, a cyclone dust collector 41, a bag filter 4, a booster fan 5, a desulfurization tower 6, a dehumidification and purification tower 9, and an SCR reaction device 36, fan 29, chimney 30, characterized in that: the sintering machine 1 is sequentially connected to the wind box 2, the cyclone dust collector 41, the bag filter 4, the booster fan 5, the desulfurization tower 6, the dehumidification and purification tower 9, and the SCR reactor 36. Fan 29, chimney 30, an electric regulating valve 3 is connected between the bellows 2 and the cyclone dust collector 41, the outlet of the fan 5 is connected to the air inlet 15 of the desulfurization tower, and the side wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com