High-temperature electrolytic in-situ desulfurization method based on magnesite desulfurizer

A high-temperature electrolysis and desulfurizer technology, applied in the direction of reducing gas emissions, can solve the problems of use, transportation and storage restrictions, increase environmental treatment and maintenance costs, and the utilization rate of magnesium needs to be improved, so as to speed up the desulfurization reaction process and achieve no pollution The effect of organic matter formation and good desulfurization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

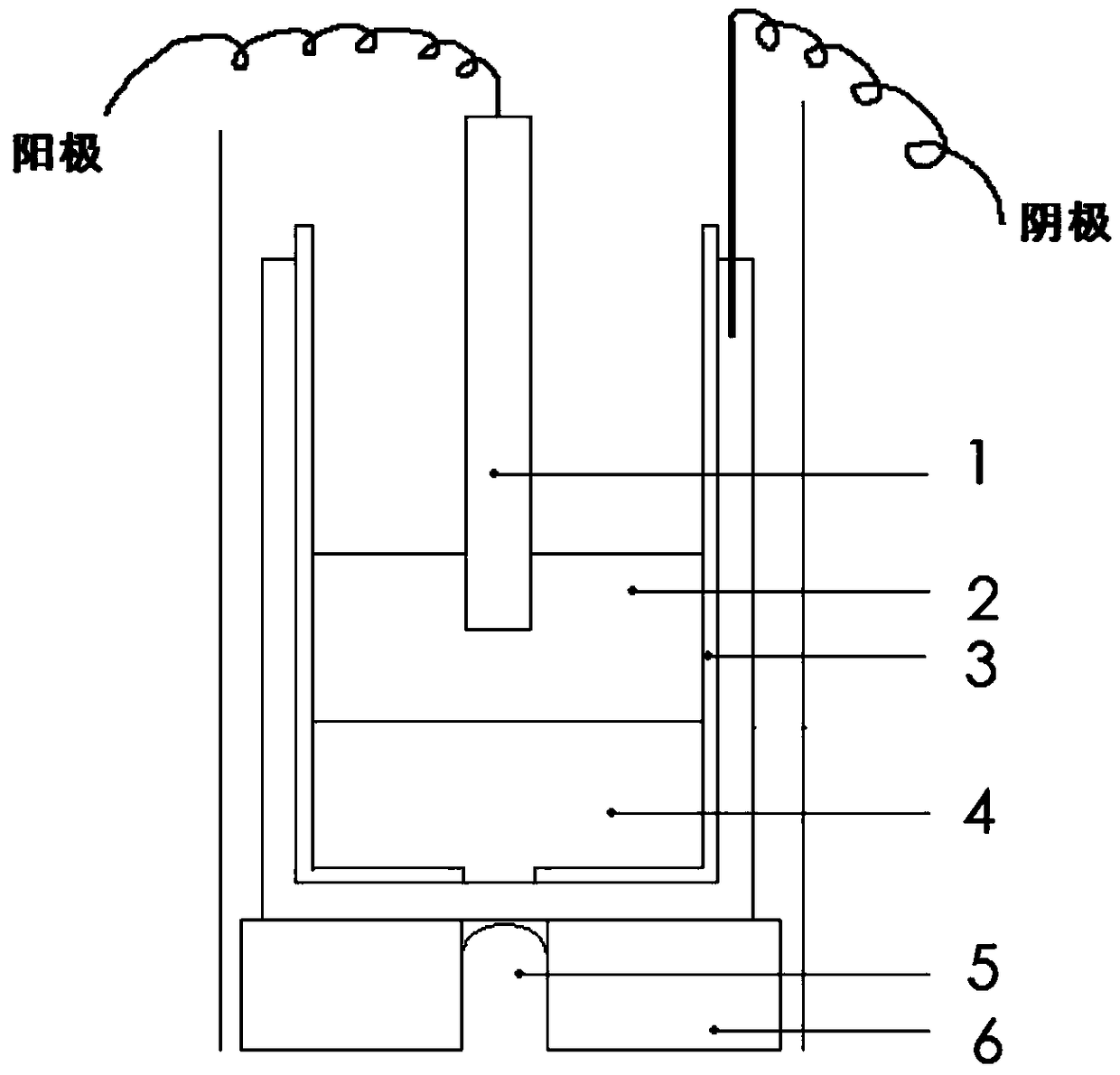

Image

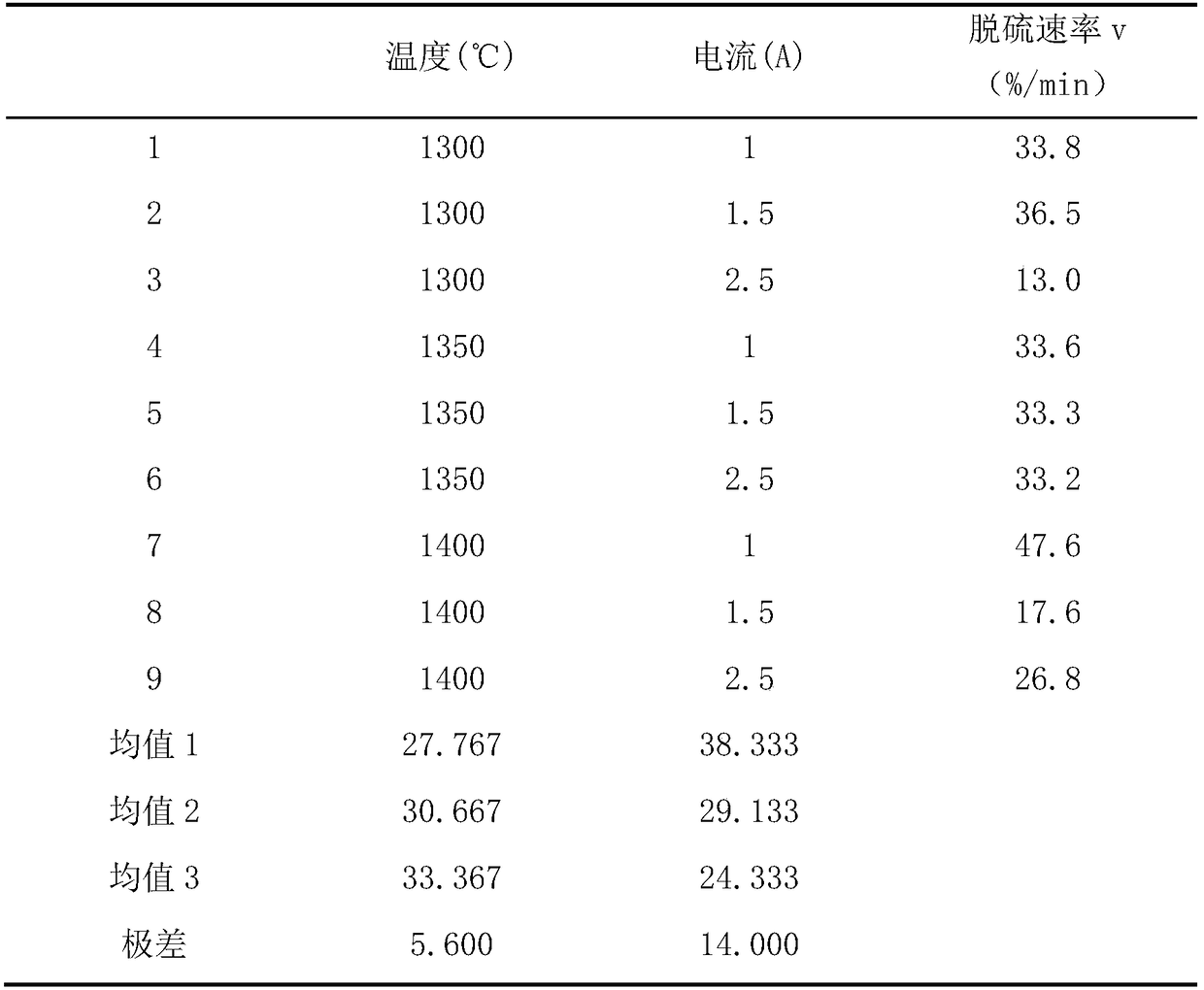

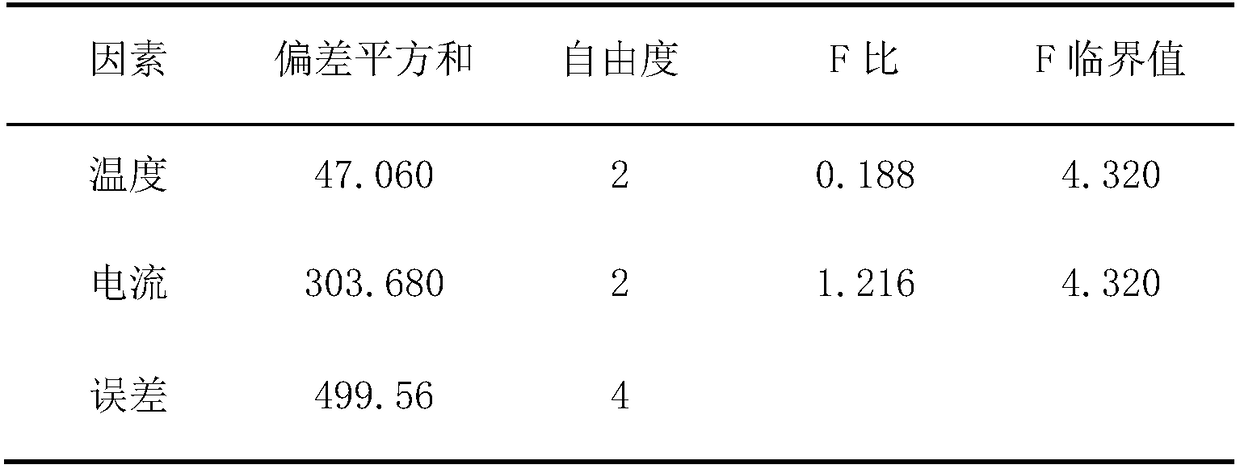

Examples

Embodiment 1

[0034] The in-situ desulfurization method by high-temperature electrolysis of magnesite-based desulfurizer, the specific steps are as follows:

[0035] a. The molten iron raw material used is blast furnace pig iron, and ferrous sulfide is selected to adjust the sulfur content in the molten iron; 100g of pig iron with an initial sulfur content of 3% is weighed, and placed in a 300°C electric blast drying oven for constant temperature drying for 2 hours;

[0036] b. The new magnesite-based desulfurizer selected is MgF 2 , CaF 2 , NaF and MgO, grind the four components separately, put them into a 300°C electric blast drying oven and dry them at a constant temperature for 2 hours; in terms of mass percentage, prepare 80g of new magnesite-based desulfurizer, and its proportion is as follows: MgF 263%, CaF 2 12%, NaF 18% and MgO 7%;

[0037] c. mixing the prepared new magnesite-based desulfurizer with pig iron to obtain a mixed material;

[0038] d. Turn on the high-temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com