Desulphurization and denitration apparatus for flue gas of coal-fired boiler

A coal-fired boiler, desulfurization and denitrification technology, applied in the direction of combined devices, climate change adaptation, climate sustainability, etc., can solve environmental pollution, dust concentration, flue gas oxygen content, high moisture content, heavy metal concentration, failure to meet emission standards, etc. problems, to achieve the effect of reducing emission concentration, high desulfurization efficiency, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

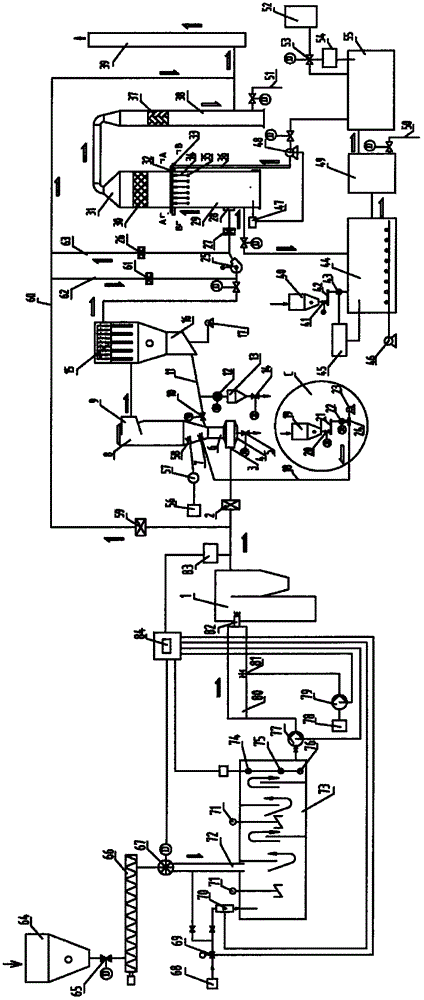

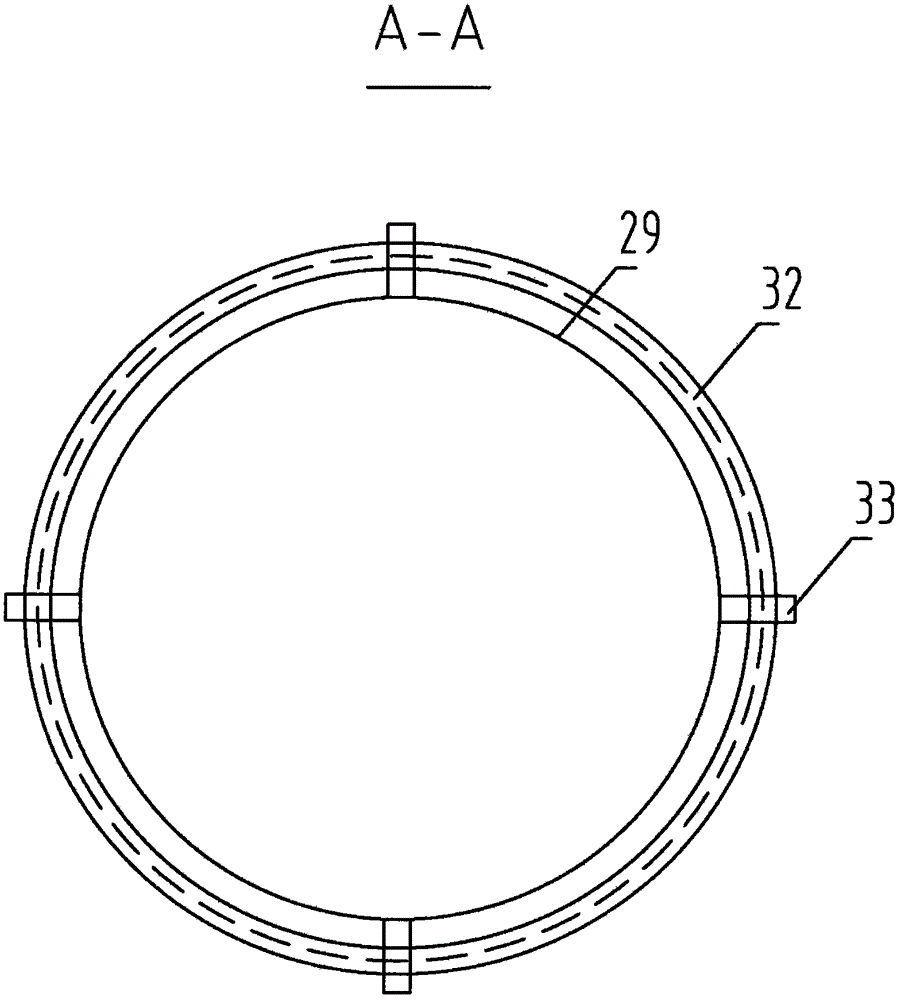

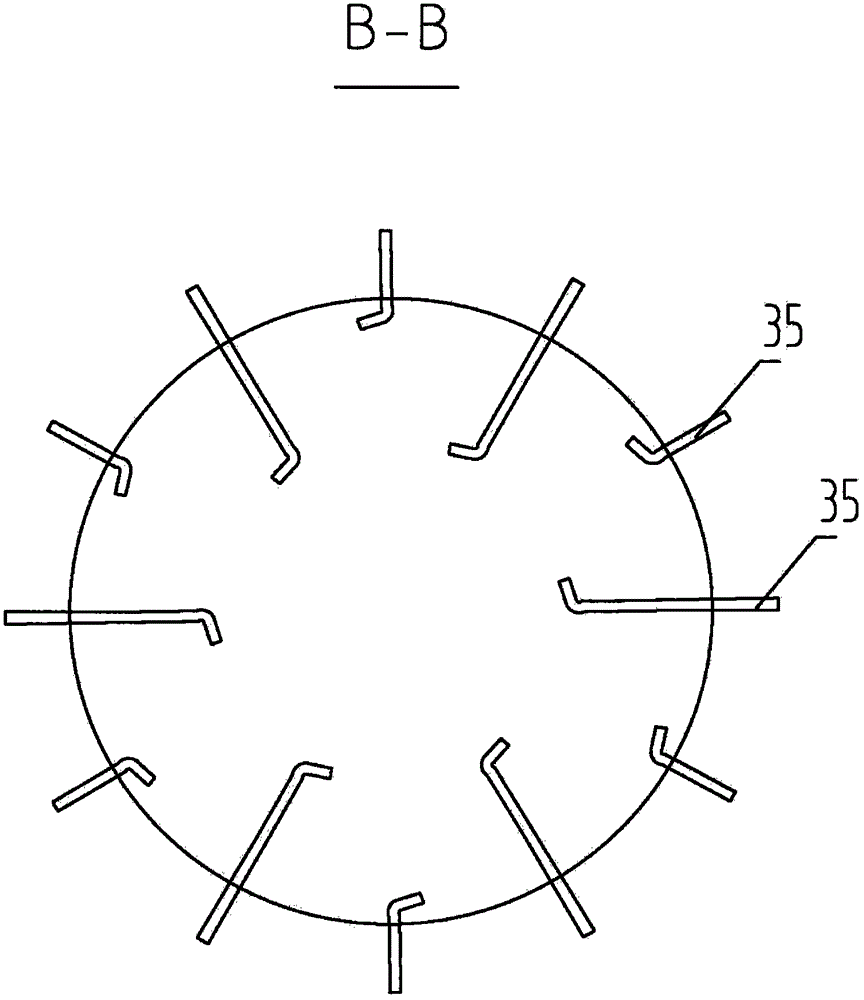

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention is a coal-fired boiler flue gas desulfurization and denitrification device, including a coal-fired boiler 1, a flue gas online monitoring and control device 83, an electric air inlet valve 2, a reaction tower 8, a bag filter 15, a fan 25, a desulfurization Tower 29, dehumidification and purification tower 30, and chimney 39, characterized in that: the coal-fired boiler 1 is sequentially connected to the flue gas online monitoring and control device 83, the electric air inlet valve 2, the reaction tower 8, the bag filter 15, the fan 25, the desulfurization Tower 29, dehumidification and purification tower 30, chimney 39, a bypass pipe 60 is connected between the coal-fired boiler 1 and the inlet of the electric air inlet valve 2, the bypass pipe 60 is connected with the inlet o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com