Techlogogy for making alpha semi-water desulfur gypsum using normal pressure salt solution method

A technology of semi-aqueous desulfurization gypsum and desulfurization process is applied in the field of utilization of by-products of flue gas desulfurization, which can solve the problems of little effective information and achieve the effects of easy control, high reliability and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

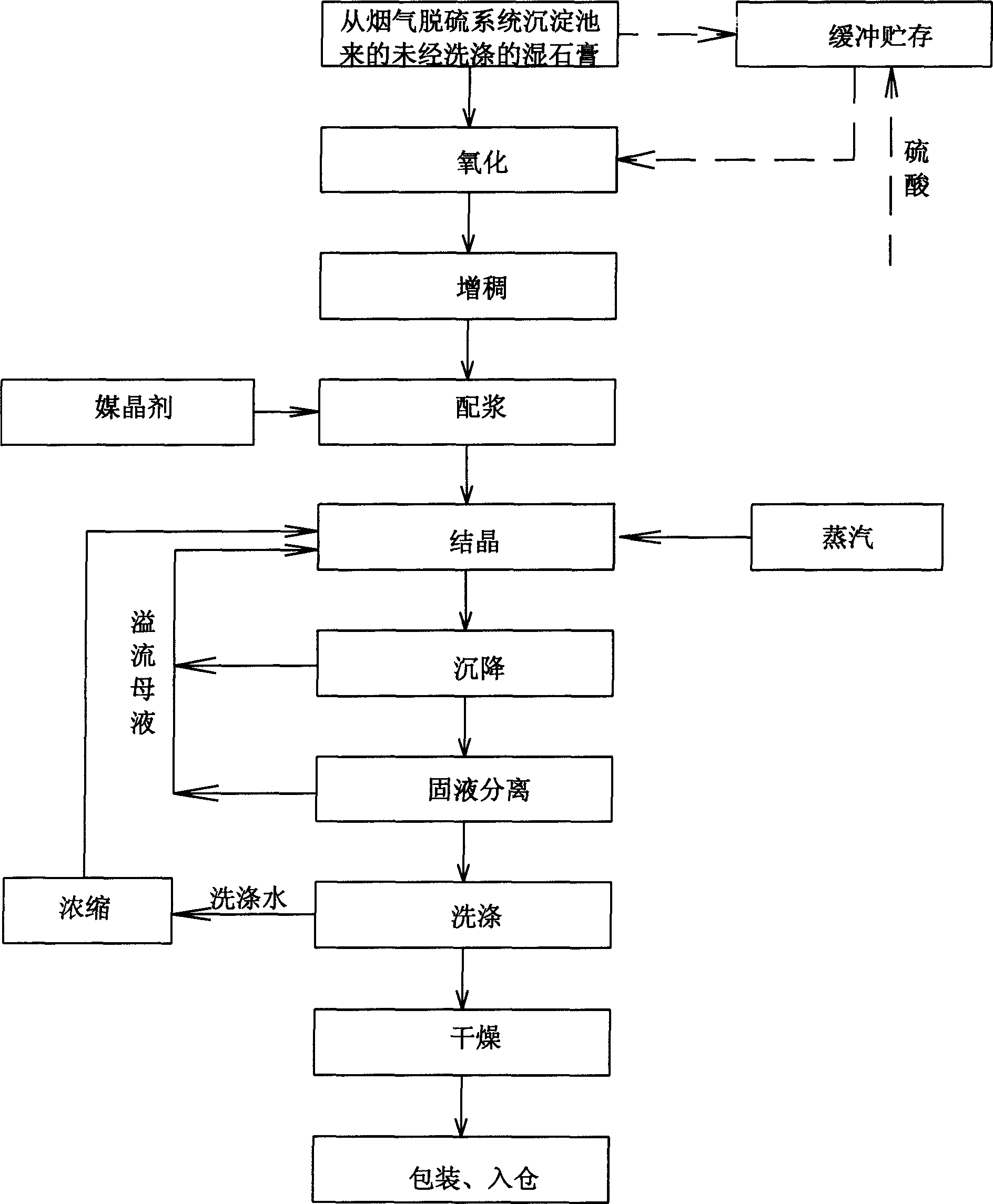

Method used

Image

Examples

Embodiment 1

[0031] The gypsum extracted from the sedimentation tank of the flue gas desulfurization system has not been washed, and the slurry concentration is about 10-20%. The slurry can be directly sent to the oxidation tank or the buffer tank, and then the slurry is sent to the gypsum treatment process to modify the gypsum . The slurry first enters the oxidation tank, the pH in the oxidation tank is about 4, and press 40Nm 3 Air / m 3 The proportion of the slurry is fed into the air to promote the complete oxidation of the desulfurized gypsum at a temperature of about 40°C. The completely oxidized gypsum enters the thickener to be thickened to 50% and is sent to the slurry tank. The solid concentration of the slurry in the slurry tank is about 10%, the total concentration of the crystal mordant is 10%, and the composition is: CaCl 2 8%, succinic acid 1%, glycerol 1%. After being uniformly mixed, the temperature is raised to 80°C by the heat exchanger, and then it enters the evaporation tank...

Embodiment 2

[0033] The gypsum extracted from the sedimentation tank of the flue gas desulfurization system has not been washed, and the slurry concentration is about 10-20%. The slurry can be directly sent to the oxidation tank or the buffer tank, and then the slurry is sent to the gypsum treatment process to modify the gypsum . The slurry first enters the oxidation tank, the pH in the oxidation tank is about 5, and press 40Nm 3 Air / m 3 The proportion of the slurry is sent to the flue gas in the desulfurization process to promote the complete oxidation of the desulfurized gypsum at a temperature of about 40°C. The completely oxidized gypsum enters the thickener to be thickened to 50% and is sent to the slurry tank. The slurry solid concentration in the slurry tank is about 10%, the total concentration of the crystal mordant is 5%, and the composition is: MgCl 2 4%, succinic acid 0.5%, glycerol 0.5%, mixed uniformly, heated to 80°C through a heat exchanger, and then enters the evaporation tank...

Embodiment 3

[0035] The gypsum extracted from the sedimentation tank of the flue gas desulfurization system has not been washed, and the slurry concentration is about 10-20%. The slurry can be directly sent to the oxidation tank or the buffer tank, and then the slurry is sent to the gypsum treatment process to modify the gypsum . The slurry first enters the oxidation tank, the pH in the oxidation tank is about 6, and press 40Nm 3 Air / m 3 The proportion of the slurry is fed into the air to promote the complete oxidation of the desulfurized gypsum at a temperature of about 40°C. The completely oxidized gypsum enters the thickener to be thickened to 50% and is sent to the slurry tank. The slurry solid concentration in the slurry tank is about 10%, and the total concentration of crystal mordant is 15%. The composition is: KCl 11%, succinic acid 4%. After mixing, the mixture is heated to 60℃ by the heat exchanger and then enters the upper part of the crystallizer. Evaporation tank. The evaporation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com