Method for using calcium sulfite type desulfurization gypsum to produce high-strength environmental-friendly type plastering gypsum

A technology of calcium sulfite and desulfurized gypsum, which is applied in the production field of plaster plaster, can solve problems such as environmental pollution and waste of useful resources, and achieve the effects of protecting the ecological environment, high flexural strength, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

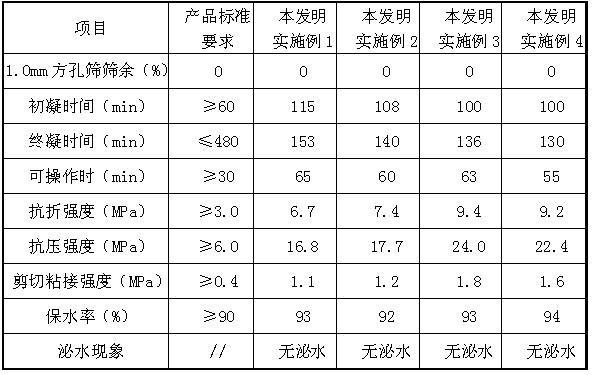

Examples

Embodiment 1

[0020] Example 1 The method for producing high-strength environment-friendly plaster plaster by utilizing calcium sulfite type desulfurized gypsum comprises the following steps:

[0021] (1) Put the calcium sulfite type desulfurization gypsum into the fluidized fluidized furnace (T300-2000×2500 type of Jingtai County Jinlong Building Materials Company), and continuously blow air into the tuyere of the fluidized fluidized furnace to make the inside of the fluidized fluidized furnace an oxidizing atmosphere and desulfurize the calcium sulfite type The gypsum is in a boiling state, and it is fried at a temperature of 480-490°C. After 20-30 minutes, its main component, calcium sulfite, is oxidized to produce type II anhydrous gypsum.

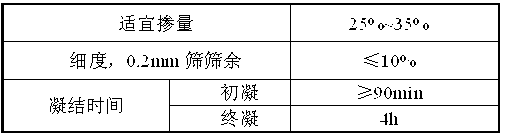

[0022] ⑵ Add 25kg of type II anhydrite activator and 0.2kg of water retaining agent in sequence to 100kg of type II anhydrite, and put it into a mixer (DSH type spiral mixer from Wuxi Hengguang Powder Equipment Co., Ltd. ) for 10 minutes, and pa...

Embodiment 2

[0025] Example 2 The method for producing high-strength environment-friendly plaster plaster by utilizing calcium sulfite type desulfurized gypsum comprises the following steps:

[0026] (1) Put the calcium sulfite type desulfurization gypsum into the fluidized fluidized furnace (T300-2000×2500 type of Jingtai County Jinlong Building Materials Company), and continuously blow air into the tuyere of the fluidized fluidized furnace to make the inside of the fluidized fluidized furnace an oxidizing atmosphere and desulfurize the calcium sulfite type The gypsum is in a boiling state, and it is fried at a temperature of 480-490°C. After 30-40 minutes, its main component, calcium sulfite, is oxidized to produce Type II anhydrous gypsum.

[0027] ⑵Add 30kg of Type II anhydrite activator and 0.4kg of water retaining agent to 100kg of Type II anhydrite in turn, and put them into a mixer (DSH type spiral mixer from Wuxi Hengguang Powder Equipment Co., Ltd. ) for 10 minutes, and pack...

Embodiment 3

[0030] Example 3 The method for producing high-strength environment-friendly plaster plaster by utilizing calcium sulfite type desulfurized gypsum comprises the following steps:

[0031] (1) Put the calcium sulfite type desulfurization gypsum into the fluidized fluidized furnace (T300-2000×2500 type of Jingtai County Jinlong Building Materials Company), and continuously blow air into the tuyere of the fluidized fluidized furnace to make the inside of the fluidized fluidized furnace an oxidizing atmosphere and desulfurize the calcium sulfite type The gypsum is in a boiling state, and it is fried at a temperature of 490-500°C. After 20-30 minutes, its main component, calcium sulfite, is oxidized to produce type II anhydrous gypsum.

[0032] ⑵Add 35kg of type II anhydrite activator and 0.3kg of water retaining agent in sequence to 100kg of type II anhydrite, and put it into a mixer (DSH type screw mixer from Wuxi Hengguang Powder Equipment Co., Ltd. ) for 10 minutes, and pac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com