Sodium-calcium dual-alkali flue gas desulfurization method and system

A flue gas and sodium-calcium technology, applied in the field of sodium-calcium double-alkali flue gas desulfurization method and system, can solve the problems of increased caustic soda consumption, decreased desulfurization efficiency, difficult reaction, etc., to improve regeneration efficiency, improve gypsum quality, and pH The effect of lowering the value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings.

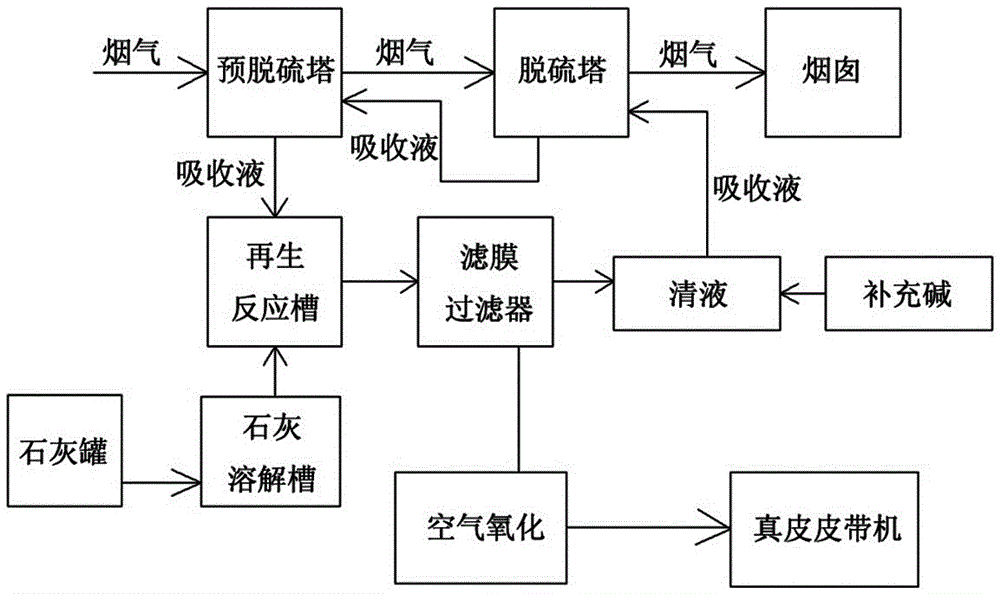

[0036] see figure 1 , a sodium-calcium double-alkali flue gas desulfurization system, including a pre-desulfurization tower, a desulfurization tower, a chimney, a regeneration reaction tank with a mechanical stirring mechanism, and a membrane filter. The flue gas outlet of the pre-desulfurization tower passes through a pipeline and the desulfurization tower The flue gas inlet of the desulfurization tower is connected to the chimney, the outlet of the regeneration reaction tank is connected to the inlet of the membrane filter through the pipeline, and the clear liquid outlet of the membrane filter is connected to the absorption liquid of the desulfurization tower through the pipeline. The inlet is connected, the outlet of the absorbing liquid of the desulfurization tower is connected with the inlet of the absorbing liquid of the pre-desulphurization tower through pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com