Reconstituted tobacco applicable to heating of non-combustion cigarettes

A technology for heating non-combustion type and reconstituting tobacco leaves, which is applied in the fields of application, tobacco, preparation of tobacco, etc., can solve the problems of affecting the product's smoking quality, consumer acceptance, insufficient tobacco aroma, small smoke volume, etc., and achieves sufficient tobacco aroma. , the effect of appropriate physiological satisfaction and high smoking volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A reconstituted tobacco leaf suitable for heating non-combustion cigarettes, the proportion of each component is as follows according to the mass percentage: 70% of tobacco raw material, 21% of smoking agent, 5% of adhesive, and 4% of flavoring for tobacco. The reconstituted tobacco leaf is made of thick Manufactured by the pulp method, the thickness is 0.10-0.20mm, and the tobacco raw materials are composed of various tobacco leaf raw materials, namely flue-cured tobacco, burley tobacco or oriental tobacco. The ratio of each type of tobacco raw materials is as follows: flue-cured tobacco 2014 Yunnan C2F: 2 parts, flue-cured tobacco 2014 Henan B1L: 1 part, flue-cured tobacco 2014 Hubei C1F: 1 part, flue-cured tobacco 2014 Fujian C1L: 1 part, Burley tobacco 2014 Hubei C3: 1 part, oriental tobacco 2014 Xinjiang B1: 1 part . The smoking agent is glycerin, the adhesive is CMC (carboxymethyl cellulose), and the flavor used for tobacco is of a light-flavored type. ;The sweet...

Embodiment 2

[0028] A reconstituted tobacco leaf suitable for heating non-combustion cigarettes, the proportion of each component is as follows according to the mass percentage: 69% of tobacco raw material, 25% of smoking agent, 4% of adhesive, 2% of flavoring for tobacco, the reconstituted tobacco leaf is made of thick Manufactured by the pulp method, the thickness is 0.10-0.20mm, and the tobacco raw materials are composed of various tobacco leaf raw materials, namely flue-cured tobacco, burley tobacco or oriental tobacco. The ratio of each type of tobacco raw materials is as follows: flue-cured tobacco 2014 Yunnan C2F: 3 parts, flue-cured tobacco 2014 Henan B1L: 3 parts, flue-cured tobacco 2014 Fujian C1L: 2 parts, Burley tobacco 2014 Hubei C3: 2 parts, oriental tobacco 2014 Xinjiang B1: 2 parts. The smoking agent is propylene glycol, the adhesive is guar gum, and the flavor used for tobacco adopts an intermediate flavor type. The rhyme is prominent; the aroma is rich and suspended.

Embodiment 3

[0030] A reconstituted tobacco leaf suitable for heating non-combustion cigarettes, the proportion of each component is as follows according to the mass percentage: 75% of tobacco raw material, 20% of smoking agent, 4% of adhesive, and 1% of flavoring for tobacco. The reconstituted tobacco leaf is made of thick Manufactured by the pulp method, the thickness is 0.10-0.20mm, and the tobacco raw materials are composed of various tobacco leaf raw materials, namely flue-cured tobacco, burley tobacco or oriental tobacco. The ratio of each type of tobacco raw materials is as follows: flue-cured tobacco 2014 Yunnan C2F: 1 part, flue-cured tobacco 2014 Henan B1L: 2 parts, flue-cured tobacco 2014 Fujian C1L: 3 parts, Burley tobacco 2014 Hubei C3: 1 part, oriental tobacco 2014 Xinjiang B1: 1 part. The smoking agent is propylene glycol, the adhesive is chitosan, and the flavor used for tobacco is of a strong flavor type. The rhyme is prominent; the aroma is rich and deep.

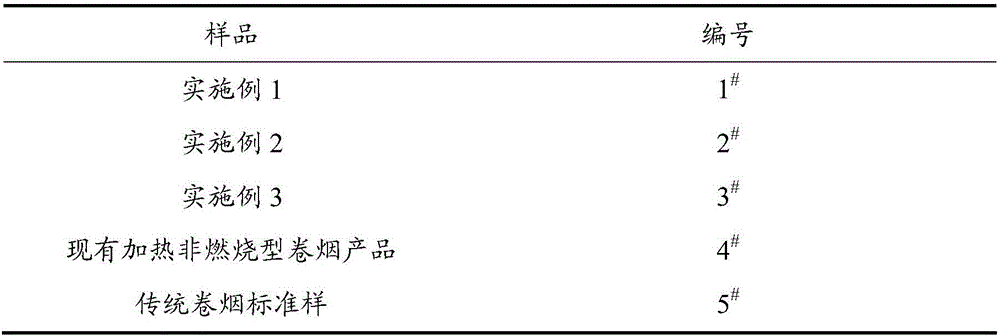

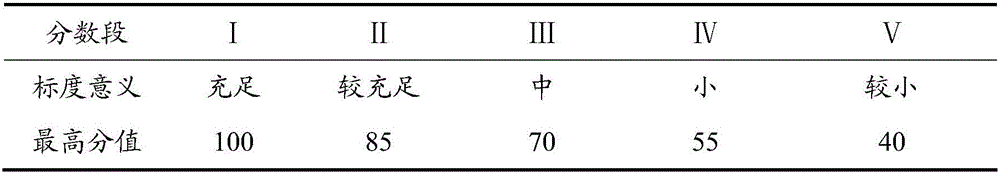

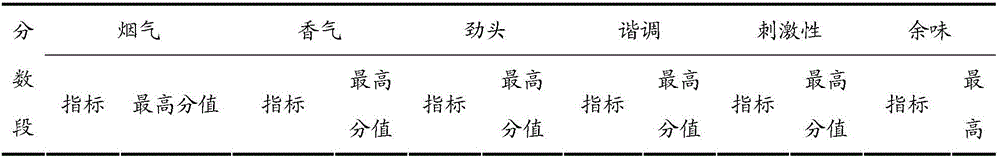

[0031] The sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com