Water-heating and electric-heating double-heat-source floor heating device adopting stainless steel corrugated tubes

A technology with stainless steel tubes and dual heat sources, which can be used in electric heating systems, household heating, heating methods, etc., and can solve problems such as poor heating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

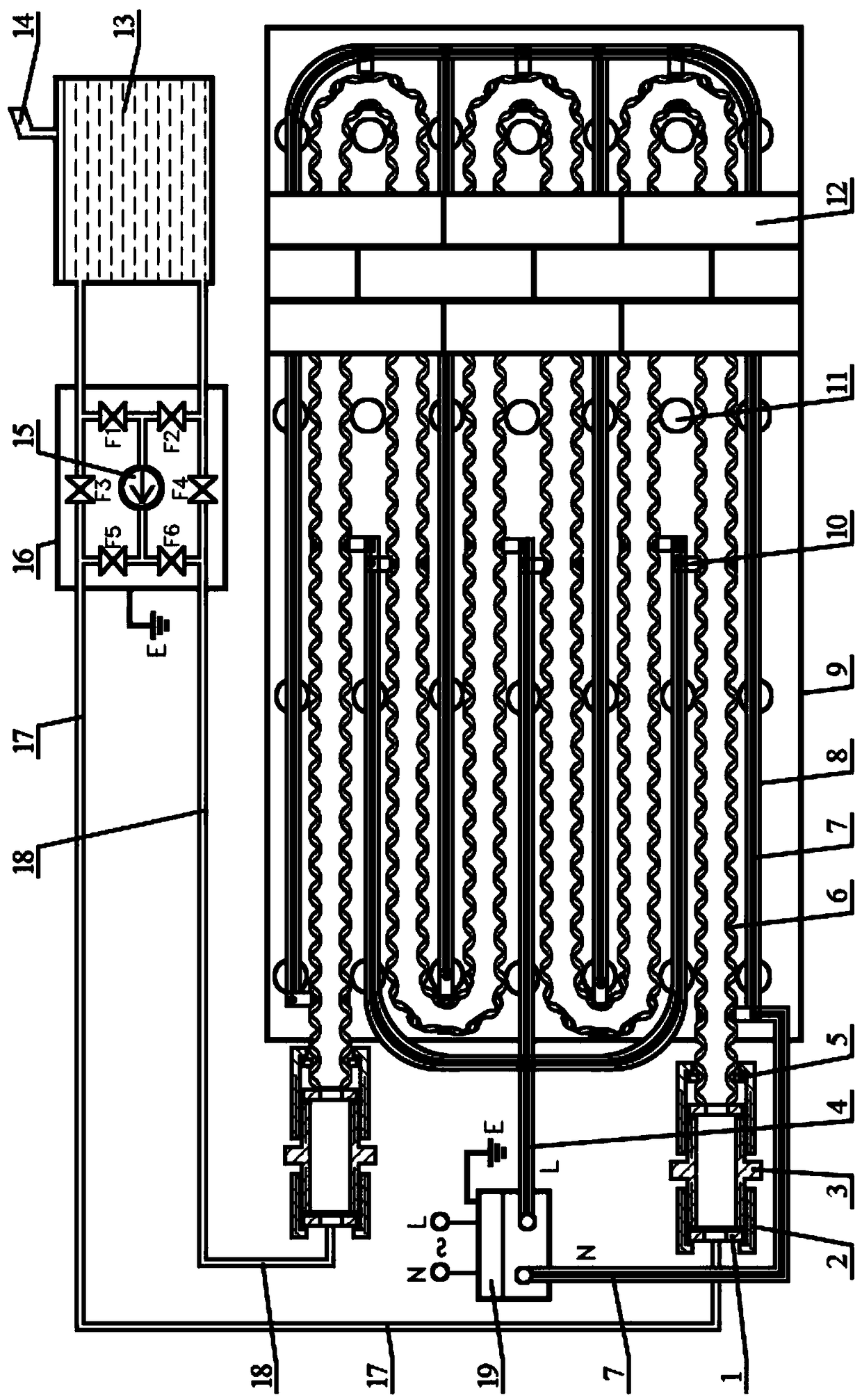

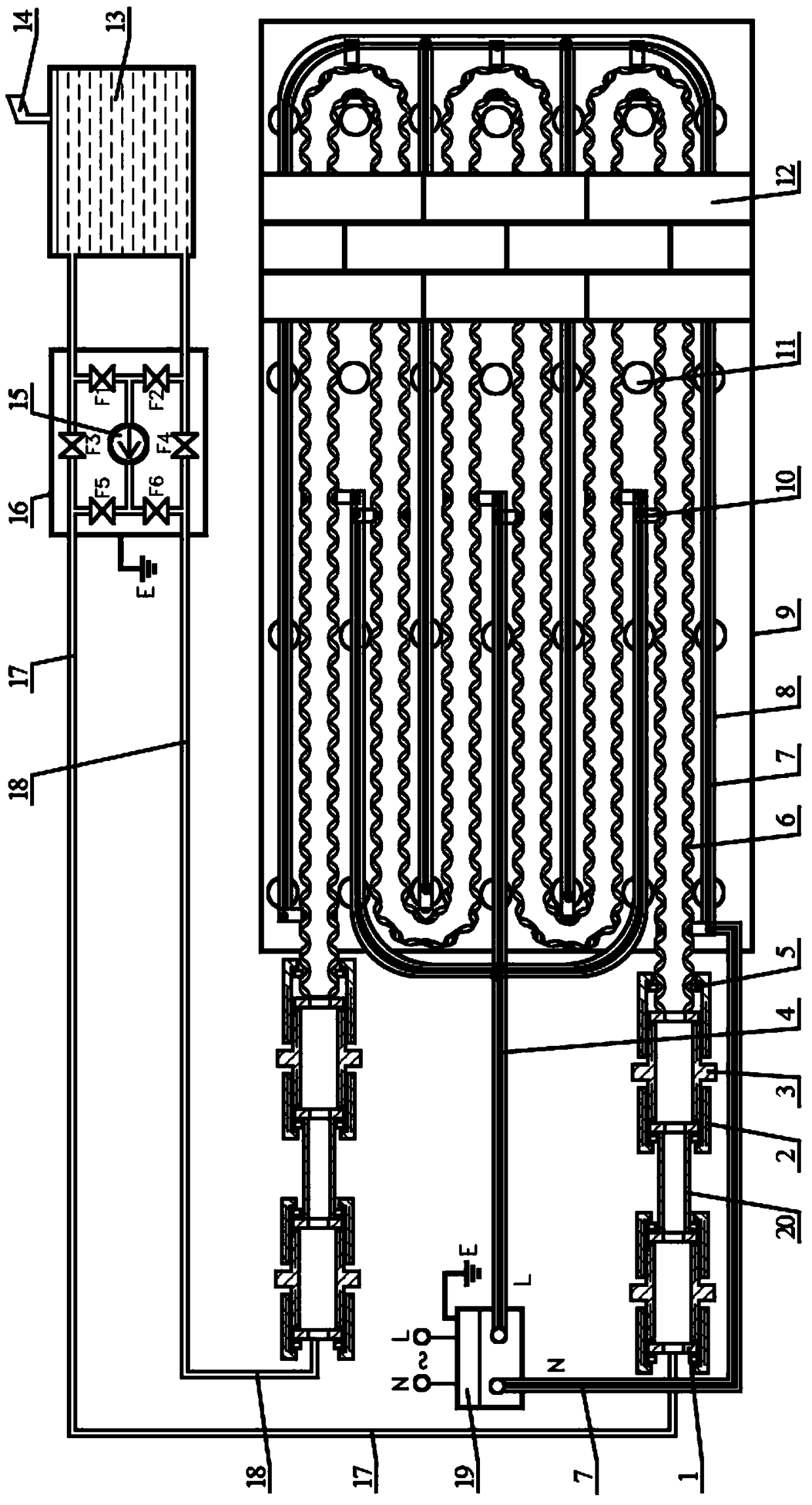

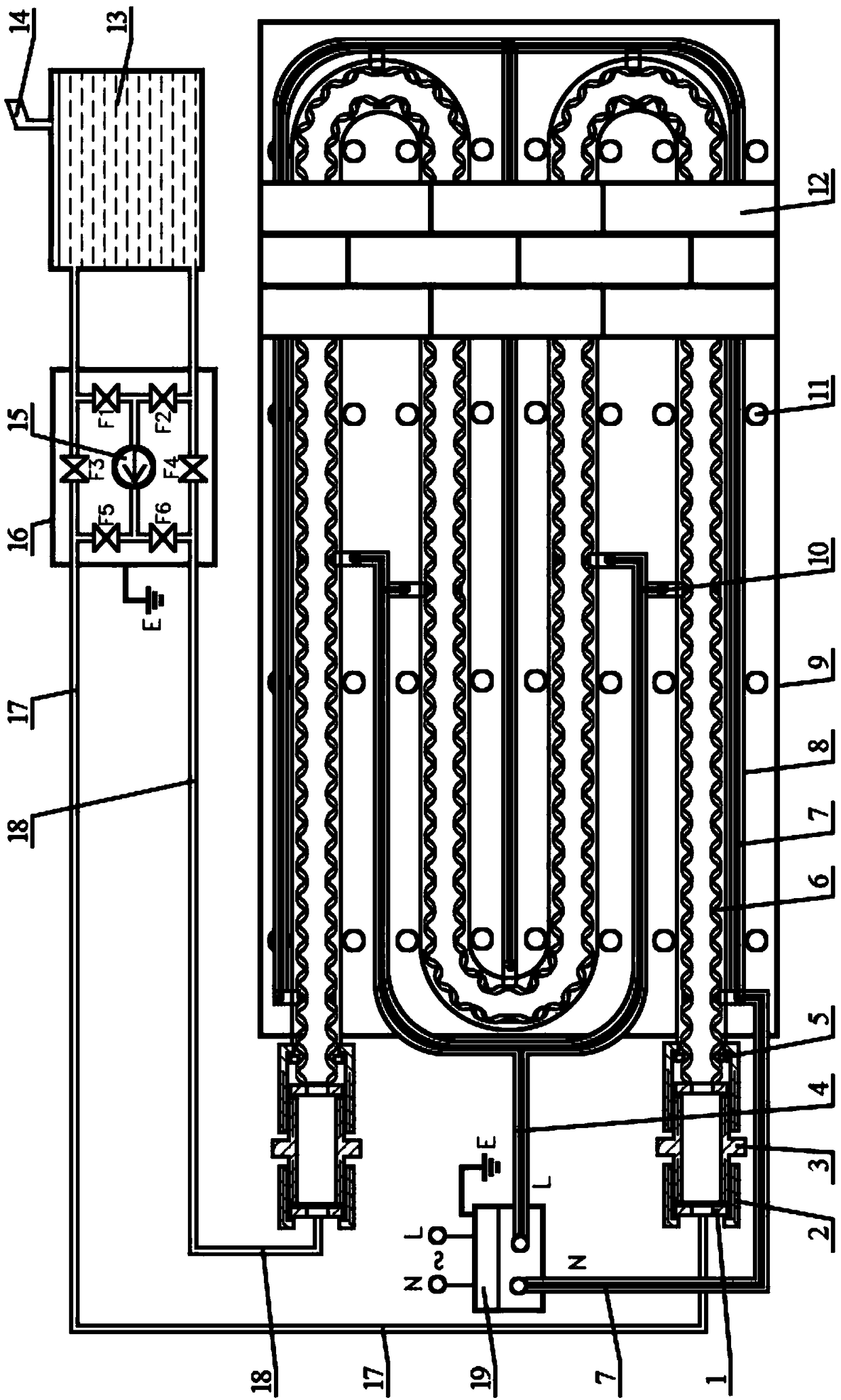

[0026] exist figure 1 In the first embodiment shown: a water heating, electric heating, double heat source corrugated stainless steel pipe floor heating device, including: sealing gasket 1, transition sealing connection pipe fitting nut 2, transition sealing connection pipe fitting pair wire 3, fire wire 4, transition sealing connection pipe fitting Positioning clasp 5, corrugated stainless steel pipe 6, zero line 7, electrical insulating layer of wire 8, electrical insulating load-bearing positioning groove plate 9, electrical connection hoop lead-out electrode 10, electrical insulating load-bearing positioning pillar 11, electrical insulating floor 12, energy storage Water tank 13, intake and exhaust pipes 14, circulating water pump 15, water distributor 16, heat supply water supply pipe 17, heat supply return water pipe 18, intelligent temperature control power supply 19.

[0027]On the outer wall of the corrugated stainless steel pipe 6, according to the specific size and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com