Flame-retardant anti-bacteria polypropylene composite material and preparation method thereof

A technology of antibacterial polypropylene and composite materials, which is applied in the field of flame-retardant antibacterial polypropylene composite materials for small household appliances and its preparation, can solve the problems of poor performance, large specific gravity, and large amount of flame retardants, and achieve excellent performance, Cost-effective, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

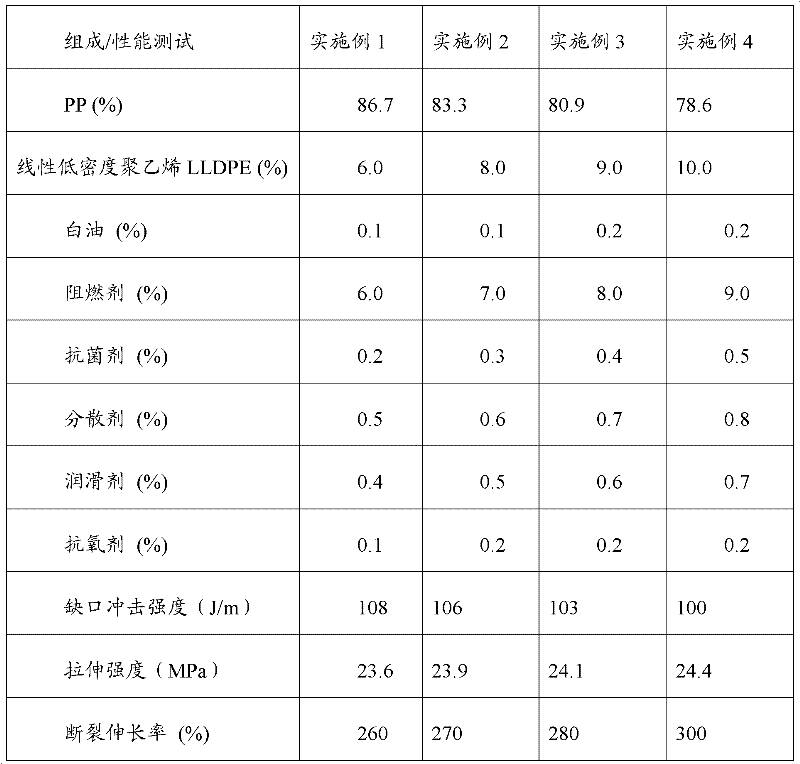

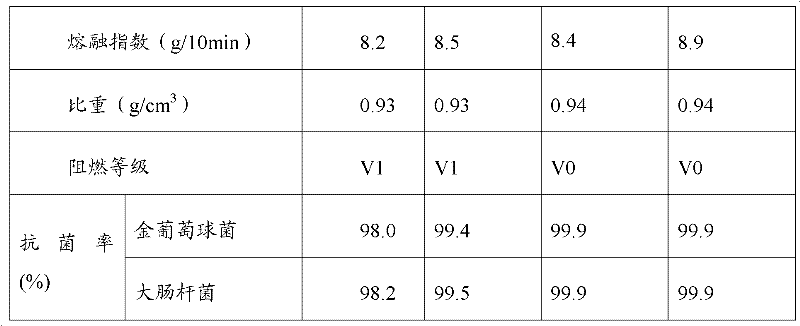

Embodiment 1

[0030] Mixing by weight ratio, PP 86.7%; LLDPE 6.0%; white oil 0.1%; flame retardant 6.0%; antibacterial agent 0.2%; dispersant 0.5%; lubricant 0.4%; antioxidant 0.1%. The mixed material is put into the hopper of the twin-screw extruder, melted and blended, extruded and granulated to form a composite material. Among them, the temperature settings of each heating zone of the screw are: zone 1 temperature: 140°C; zone 2: 140°C; zone 3: 150°C; zone 4: 160°C; head: 180°C; residence time 3-4min. The pressure is 15MPa.

Embodiment 2

[0032] Mixing by weight, PP 83.3%; LLDPE 8.0%; white oil 0.1%; flame retardant 7.0%; antibacterial agent 0.3%; dispersant 0.6%; lubricant 0.5%; antioxidant 0.2%. The mixed material is put into the hopper of the twin-screw extruder, melted and blended, extruded and granulated to form a composite material. Among them, the temperature settings of each heating zone of the screw are: zone 1 temperature: 140°C; zone 2: 150°C; zone 3: 150°C; zone 4: 160°C; head: 170°C; residence time 3-4min. The pressure is 15MPa.

Embodiment 3

[0034] Mix according to weight ratio, PP 80.9%; LLDPE 9.0%; white oil 0.2%; flame retardant 8.0%; antibacterial agent 0.4%; dispersant 0.7%; lubricant 0.6%; antioxidant 0.2%. The mixed material is put into the hopper of the twin-screw extruder, melted and blended, extruded and granulated to form a composite material. Among them, the temperature settings of each heating zone of the screw are: zone 1 temperature: 150°C; zone 2: 150°C; zone 3: 160°C; zone 4: 160°C; head: 180°C; residence time 3-4min. The pressure is 15MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com