Disposable cigarette cartridge and heating non-combustion cigarette utilizing multiple disposable cigarette cartridges

A heating non-combustion, disposable technology, applied in the direction of smokers' supplies, applications, tobacco, etc., can solve the problems of affecting the quality of smoke suction, less heat generated by heating components, and insufficient user satisfaction, etc., to achieve the effect of atomization Good, high heating efficiency, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

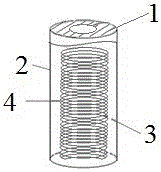

[0040] This embodiment provides a disposable cartridge and heat-not-burn smoke using the disposable cartridge. The structure of the pod is as follows figure 1 As shown: including the sealing film 1, the outer wall of the pod 2, the cavity 3 and the metal element 4 inside the cavity 3, the pod has a through inner hole; the metal element is a spring-shaped spiral coil, which is made of an iron wire with a diameter of 1.0mm Made around 20 turns, the diameter of the helical coil is 0.5cm, and the height is 2.5cm.

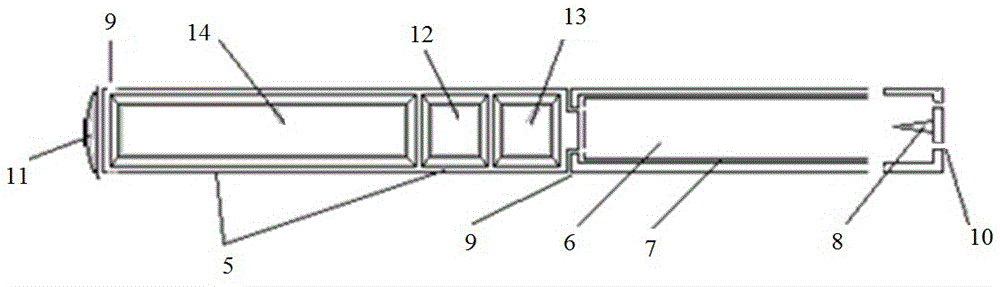

[0041] This embodiment provides a heat-not-combust smoke using a disposable pod, the schematic diagram of which is shown in figure 2 As shown: including the housing 5, there is a housing chamber 6 and other components for placing disposable pods in the housing 5. The inner wall of the housing chamber 6 has an induction coil 7, and the induction coil 7 is passed an alternating current to make the helical coil generate Electric current, the inner wall of the accommoda...

Embodiment 2

[0056] The heat-not-burn smoke provided in this example is basically the same as that in Example 1, the difference lies in the structure of the metal elements in the disposable pod, which are iron sheets, closed triangular iron rings, closed cylindrical iron rings, See you separately image 3 , Figure 4 and Figure 5 . We respectively investigated the heating and atomization effects of different shapes of heating materials (Table 2). The metal components were all covered by shredded tobacco, and the amount of shredded tobacco was 2.00g.

[0057] The results show that if the area of the heating element is the same, the change of the shape has little effect on the heating efficiency, and the difference in the smoke effect is not obvious.

[0058] Table 2 Smoke generation of metal components of different shapes

[0059]

Embodiment 3

[0061] This example mainly investigates the heat generation of metal elements of different shapes. The structure of heating non-combustion smoke is the same as that of Example 1. Three iron wires, a single piece of iron sheet and a closed cylindrical iron ring are selected for the disposable pods. With 2.00 g of cut tobacco, the metal element is completely covered by the cut tobacco.

[0062] The results show that although the total amount of heat released by heating the iron wire is the least, the surface temperature in contact with the smoking substance is high, so the amount of atomization released is the largest.

[0063] Table 3 Smoke Effects of Metal Components of Different Shapes

[0064]

[0065] The above experiments show that the iron wire or its winding into a helical coil is beneficial to fuming and atomization, and is suitable for electromagnetic induction heating of non-combustion smoke (low temperature smoke).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com