Aerosol generating product with sectional aerosol generating substrate rod

An aerosol generation and segmented technology, which is applied in the manufacture of cigars, e-liquid filter elements, tobacco, etc., can solve problems such as inability to bond, affect aerosol release, and uneven dispersion of adhesives, so as to ensure the amount of smoke Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

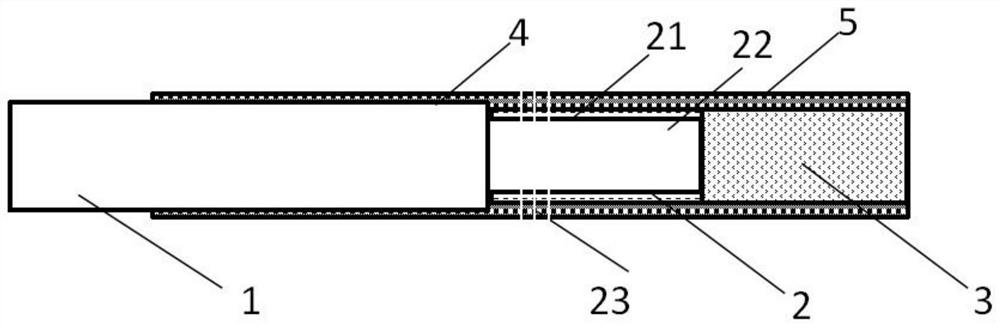

[0057] This embodiment is an aerosol generating product with a segmented aerosol generating matrix rod, which includes a smoking core material segment 1, a breathable hollow segment 2 and a filter segment 3;

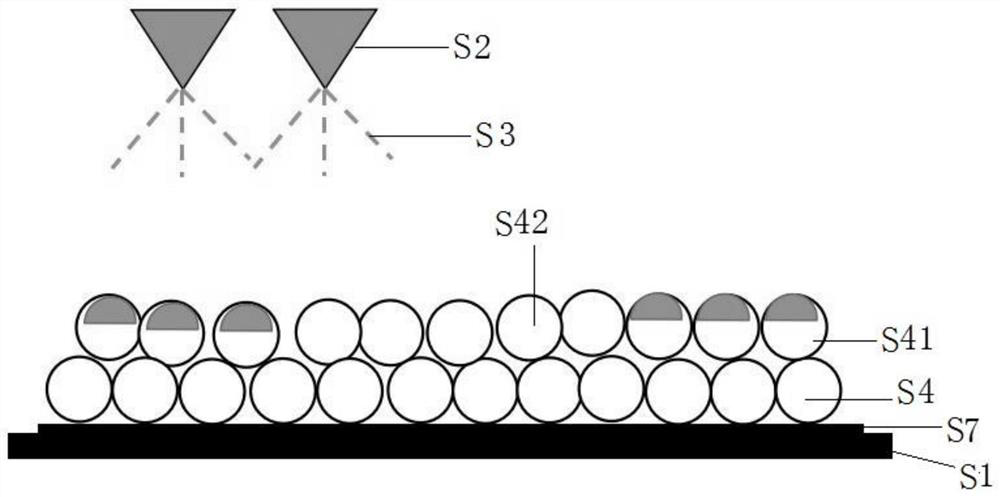

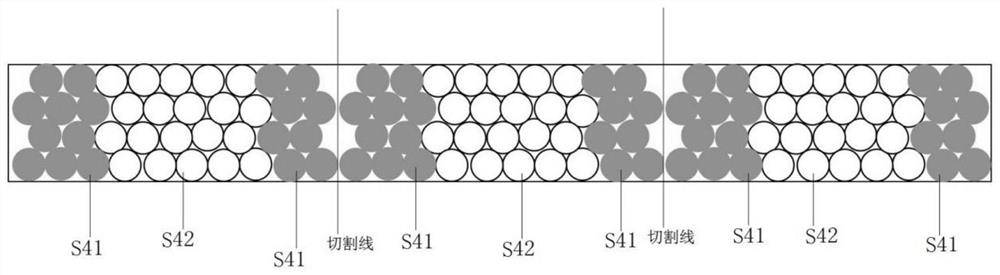

[0058] The smoking core material segment 1 includes a segmented aerosol generating matrix rod and an anti-seepage / heat conduction cigarette paper wrapping the segmented aerosol generating matrix rod, and the two ends of the segmented aerosol generating matrix rod are A stub segment 11 formed by bonding sized tobacco particles, with a loose particle segment 12 formed by unsized tobacco particles in the middle;

[0059] The air-permeable hollow section 2 and the filter section 3 are wrapped by forming paper 5 to form a mouthpiece, and the smoking core section 1 and the mouthpiece are connected by tipping paper 4 .

[0060] The tube wall of the air-permeable hollow section 2 is made of paper, which is grooved and corrugated. Ventilation holes 23 are arranged on the pipe wa...

Embodiment 2

[0070] Such as Figure 5 , this embodiment is an aerosol generating product with a segmented aerosol generating matrix rod, the preparation method of the aerosol generating matrix rod is the same as in Example 1, the difference is only in the structure of the cigarette, the aerosol generating product of this embodiment On the basis of embodiment 1, a functional section 6 is added. When the functional section 6 is located between the air-permeable hollow section 2 and the filter section 3, the functional section 6 can be a hollow tube, and the hollow tube wall For breathable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com