Coal ash type fire enhancing brick

A technology of fly ash and fire bricks, which is applied in the field of fly ash reuse, can solve the problems of unstable heat, low heat, and high energy consumption, so as to improve the smoke elimination effect, reduce the smoke output, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0052] Fly ash type fire bricks, including fly ash, coal slime, briquettes, solid fuel and coal surface. In weight percent, each component is represented in the table below:

[0053]

fly ash slime coal surface Briquettes solid fuel calorific value Example 1 50 20 20 5 5 4300 Example 2 40 30 20 3 7 4500 Example 3 40 20 30 7 3 4700 Example 4 48 25 20 2 5 4420

[0054] Wherein, in the solid fuel, the parts by weight of each component are as follows:

[0055] 12 parts of sawdust; 20 parts of paraffin; 8-9 parts of alcohol.

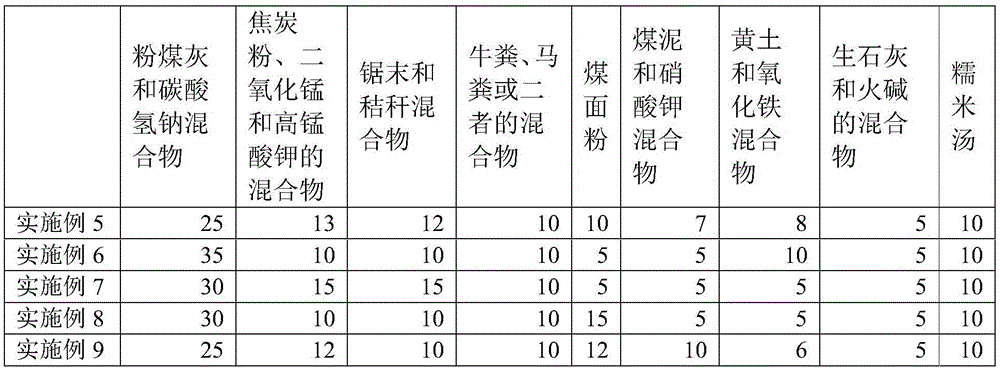

Embodiment 5-9

[0057] Fly ash-type fire bricks, in volume percentage, the content of each component is shown in the following table:

[0058]

[0059] Among them, in the mixture of coke powder, manganese dioxide and potassium permanganate, the weight ratio of each component is 5:2:3;

[0060] Wherein, in the mixture of sawdust and straw, the weight ratio of each component is 2.5:1;

[0061] Wherein, in the mixture of quicklime and caustic soda, the weight ratio of each component is 4:1;

[0062] Wherein, in the mixture of fly ash and sodium bicarbonate, the weight ratio of each component is 10:1;

[0063] Wherein, in the mixture of loess and iron oxide, the weight ratio of each component is 3:1;

[0064] Wherein, in the mixture of coal slime and potassium nitrate, the weight ratio of each component is 5:1.

[0065] The coal-burning combustion aid contains an oxidant that provides an oxygen source, which can decompose oxygen under high temperature conditions to promote the complete comb...

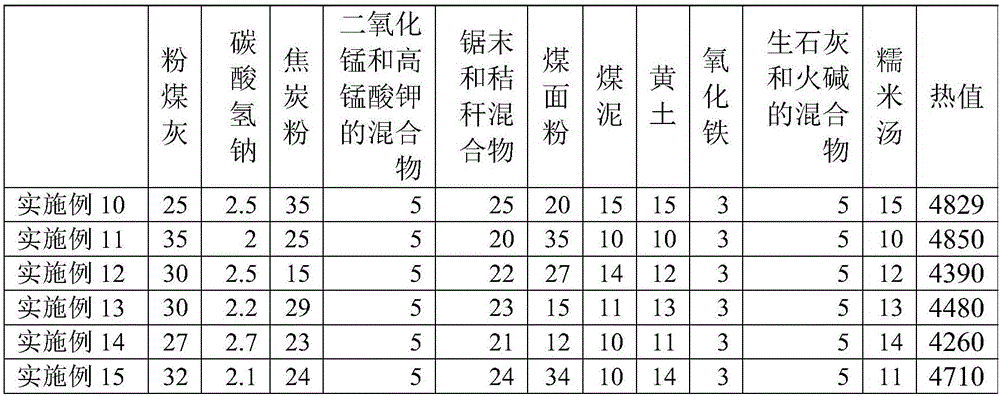

Embodiment 10-15

[0072] A kind of fly ash type fire brick, the weight percent of its each component is shown in the following table:

[0073]

[0074] The coal-burning combustion aid contains an oxidant that provides an oxygen source, which can decompose oxygen under high temperature conditions to promote the complete combustion of coal. In addition, the catalyst without corrosive substances can effectively reduce the dissociation energy of oxygen and the activation energy required for carbon combustion, strengthen the combustion of coal, and play a strong role in supporting combustion, increasing energy, and saving coal. By adding a small amount of additives to these mixtures to promote the complete combustion of coal, it can not only reduce the heat loss of incomplete combustion, but also reduce the emission of soot. Under the same volume, its combustion time is 1.6-2.2 times that of traditional briquette, and its average heat mass is 4590 kcal, which is about 40-50% higher than that of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com