Large-capacity energy-saving environment-friendly bulk curing barn

An energy-saving, environment-friendly, intensive barn technology, applied in the field of flue-cured tobacco, can solve the problems of reduced heat transfer efficiency of the heating system, waste of fuel, and low work efficiency, and achieve the effects of effective use of space, reduction of labor costs, and improvement of turnover efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

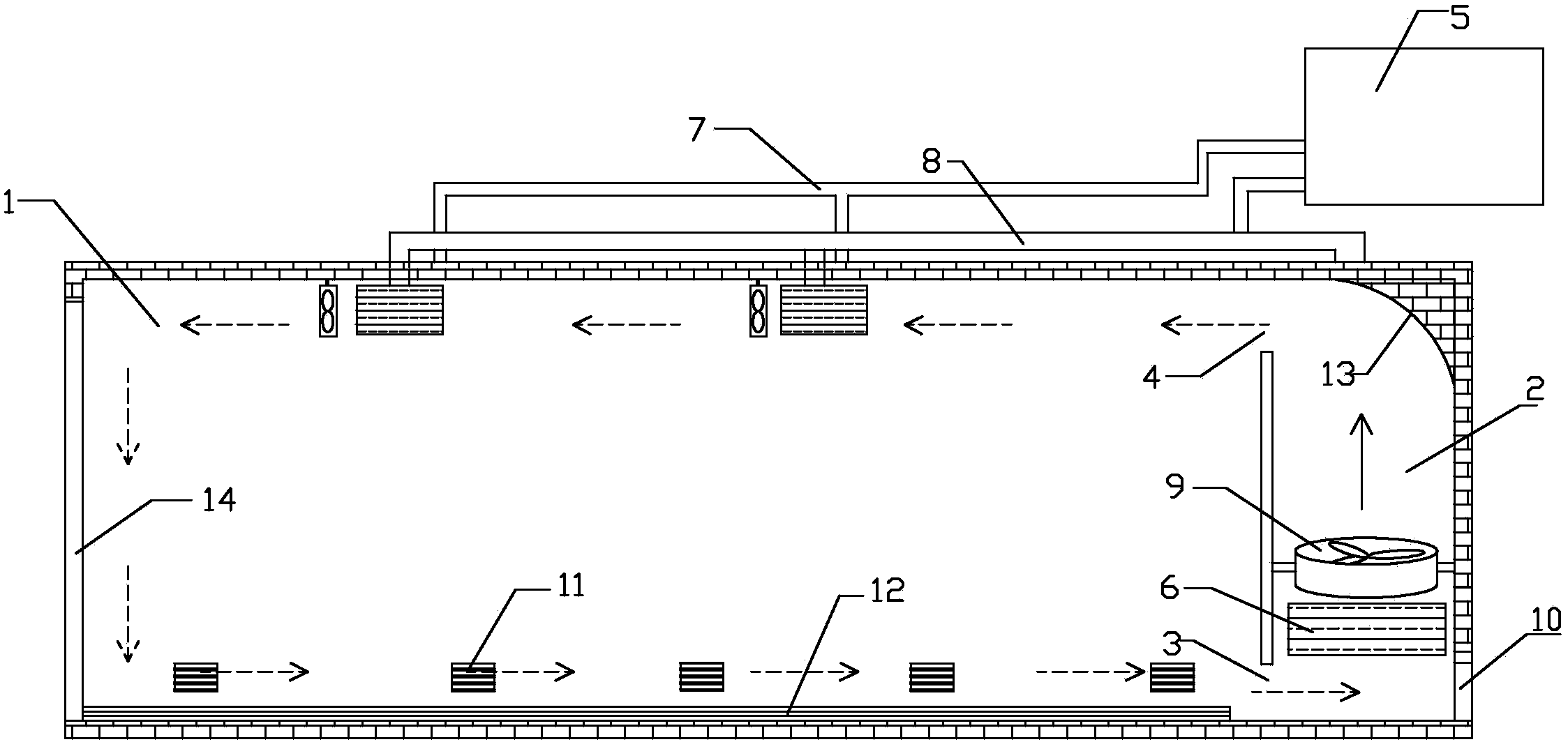

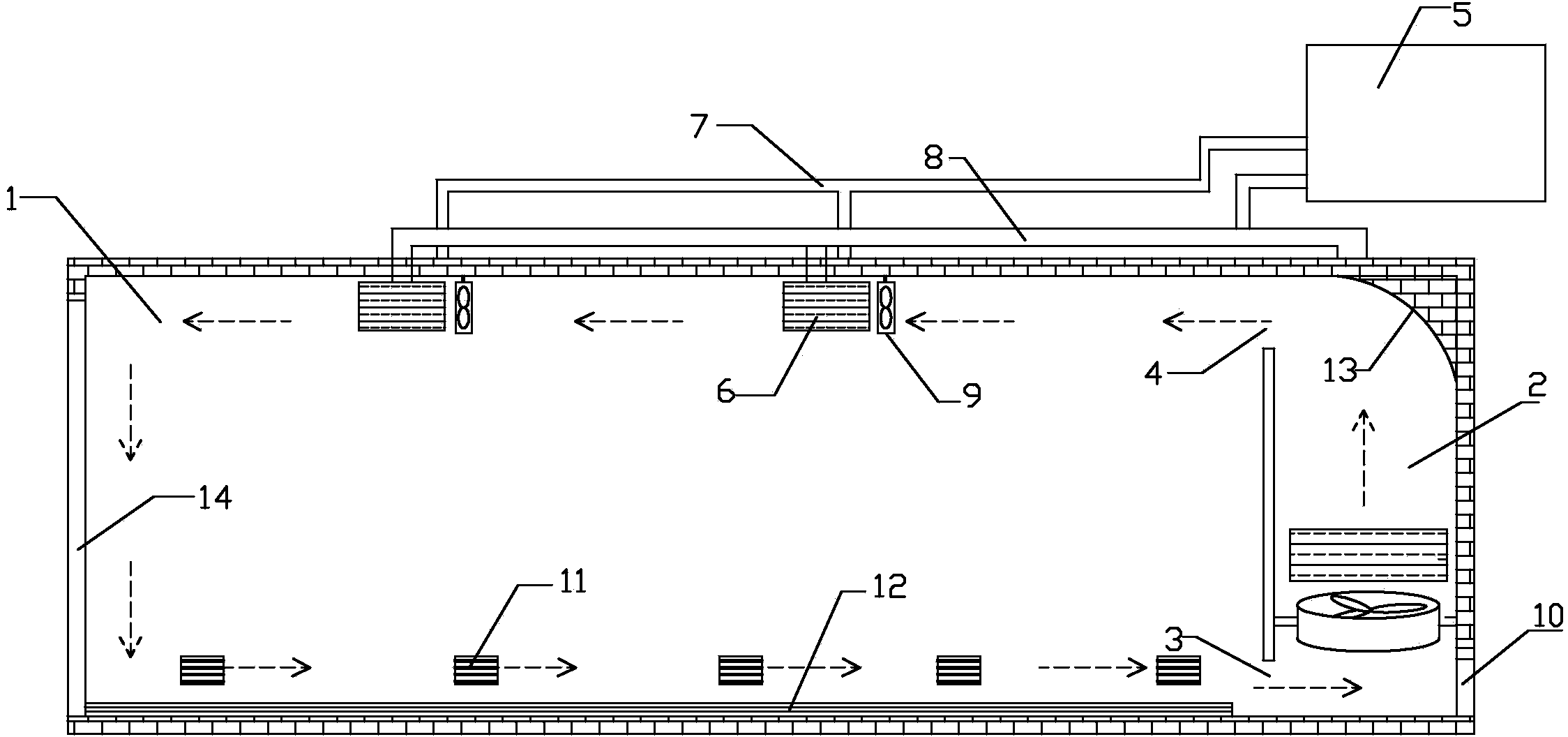

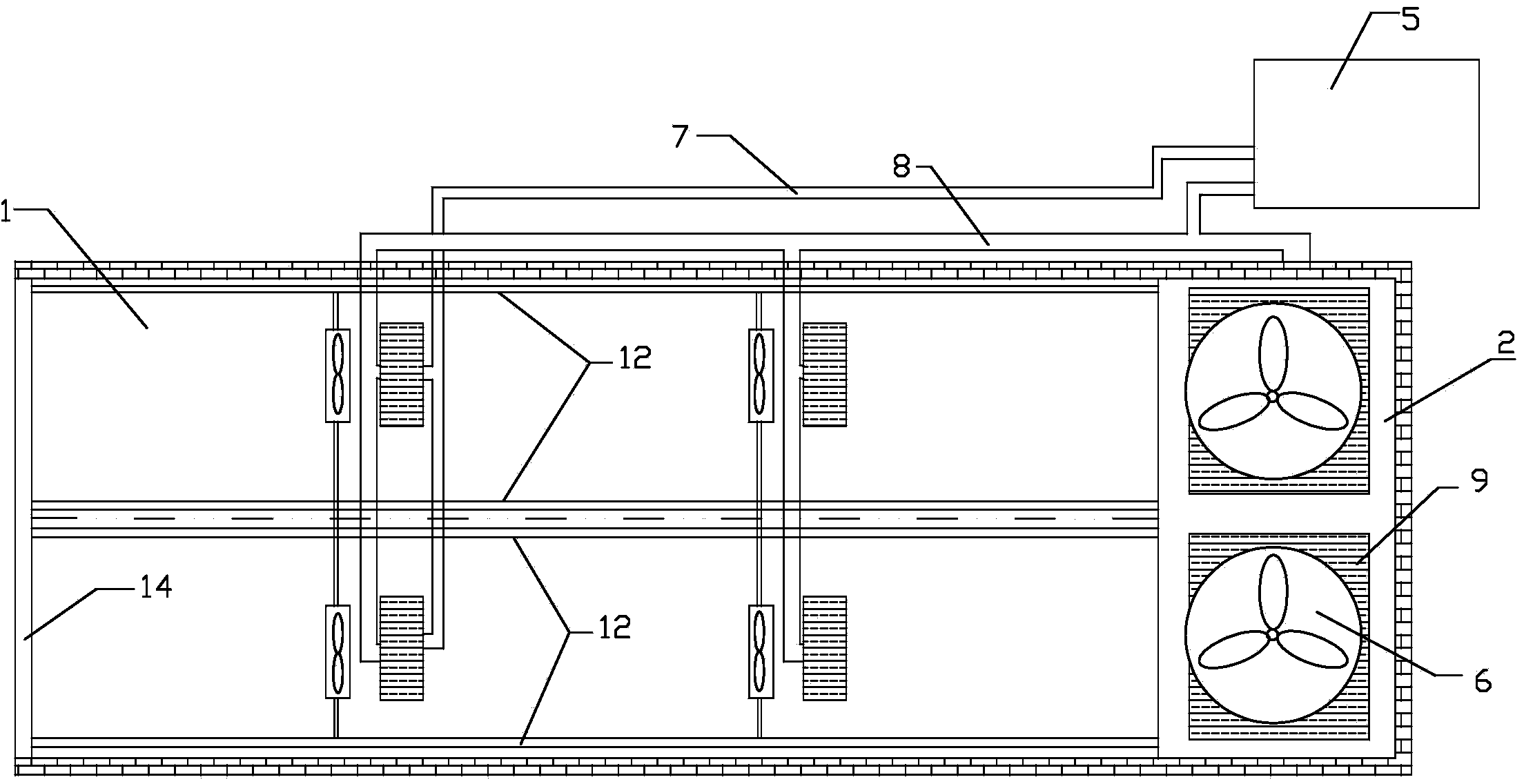

Method used

Image

Examples

Embodiment

[0036] Example: For the middle tobacco leaves of Yunyan 87 in a certain production area in Hubei Province, the following two kinds of flue-cured rooms were used for baking comparison, and the curing process used a three-stage baking process, wherein T1 was baked by hanging rods in ordinary dense curing rooms. Tobacco roasting (the existing conventional way of flue-cured tobacco), T2 adopts a large-capacity energy-saving and environmentally-friendly intensive curing room according to the present invention and uses drawer-type mobile tobacco racks to load tobacco for baking, and conducts energy consumption statistics for baking. The economic properties, appearance quality, chemical composition and sensory quality of tobacco leaves were compared. The results are shown in Table 1-5.

[0037] Table 1 Comparison of smoke loading and energy consumption in different barns

[0038]

[0039] Note: Coal consumption is calculated as loose coal, 800 yuan per ton; electricity price is 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com