Combustion optimizing control system of circulating fluidized bed boiler in wide-range change of load

A circulating fluidized bed and boiler combustion technology, which is used in fluidized bed combustion equipment, control systems, and fuels burned in a molten state to maintain pressure, improve commissioning rates, and avoid disturbances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described below in conjunction with the accompanying drawings.

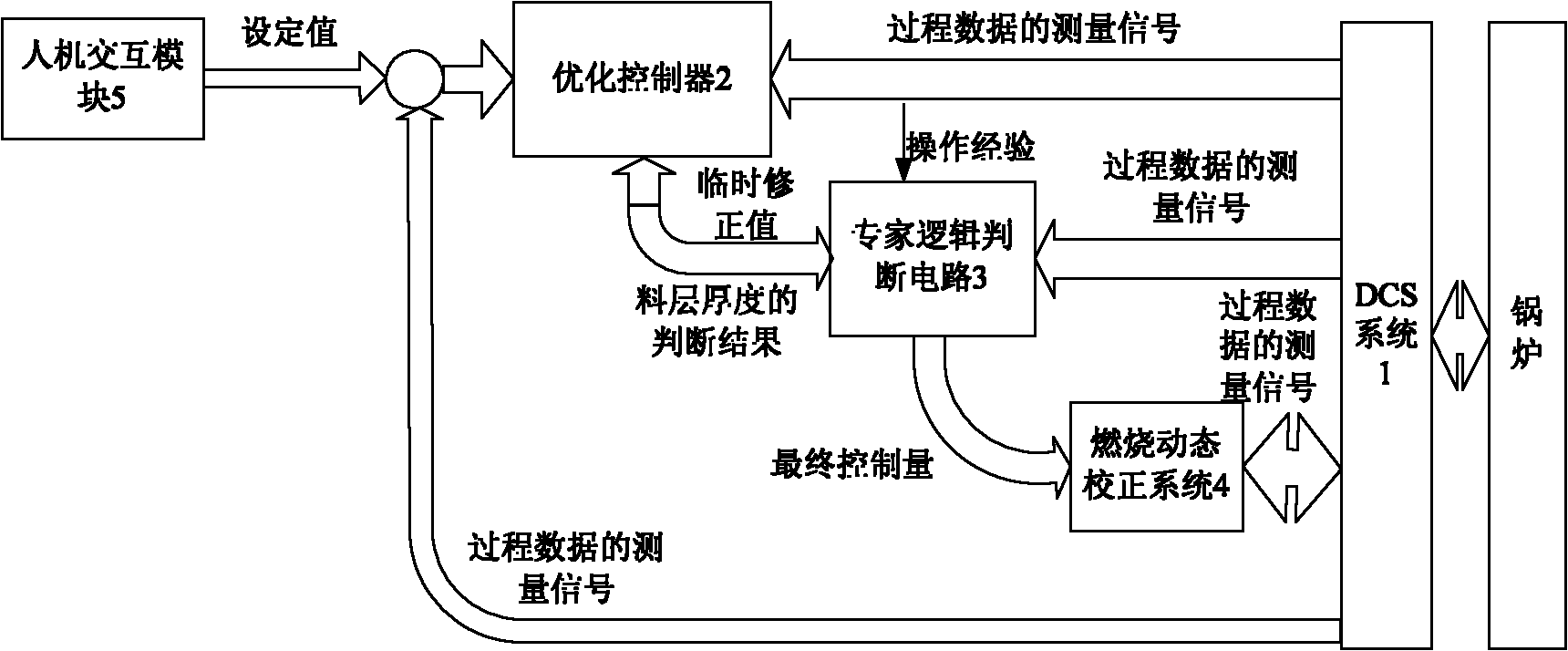

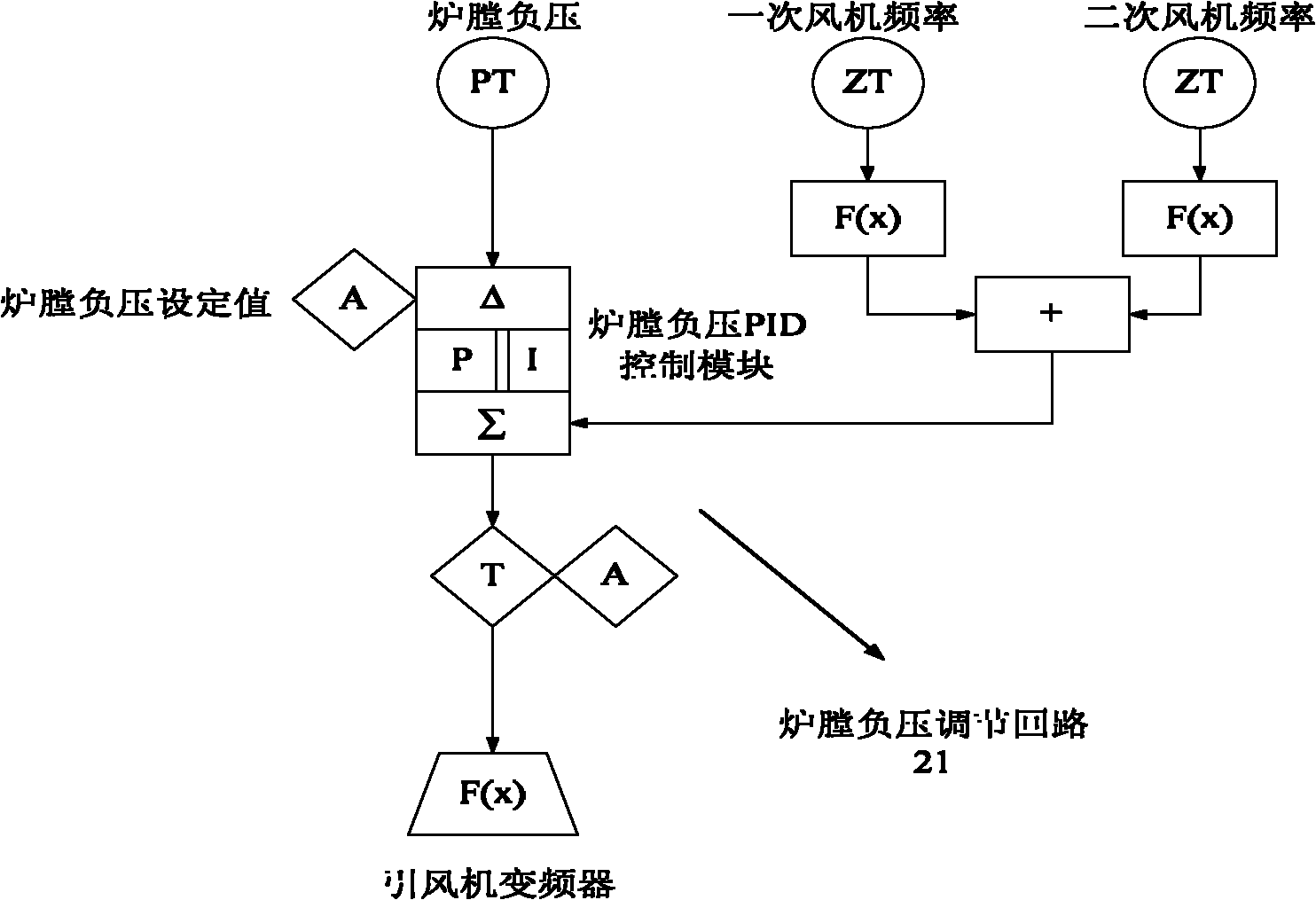

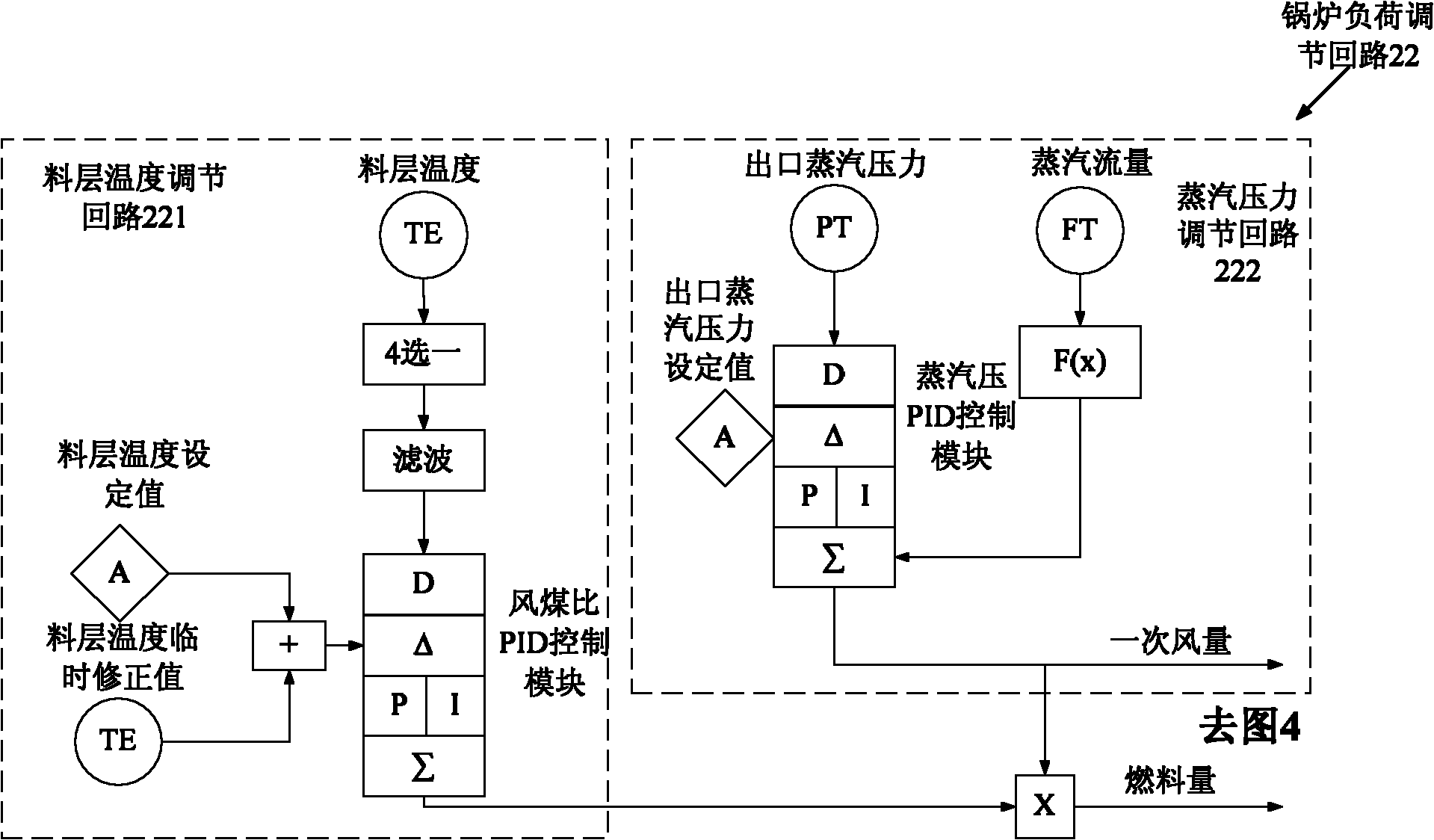

[0029] likefigure 1 As shown, the circulating fluidized bed boiler combustion optimization control system of the present invention includes a DCS system 1, an optimization controller 2, an expert logic judgment circuit 3, a combustion dynamic correction system 4 and a human-computer interaction module 5, wherein the optimization controller 2 includes a furnace Negative pressure regulation circuit 21, boiler load regulation circuit 22 and furnace material distribution estimator 23, wherein boiler load regulation circuit 22 also includes material layer temperature regulation circuit 221, steam pressure regulation circuit 222, flue gas oxygen and sulfur content regulation circuit 223. DCS system 1 is an industrial process control system, which is used to collect measurement signals of process data in circulating fluidized bed boilers, and input these measurement signals into opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com