Steam turbine generating heating system with double running modes

A technology of operation mode and heating system, applied in steam engine installations, machines/engines, mechanical equipment, etc., can solve the problem of reducing the share of exhaust steam of steam turbines, and achieve the effect of reducing coal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The following description is merely exemplary in nature and not intended to limit the disclosure, application or use. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

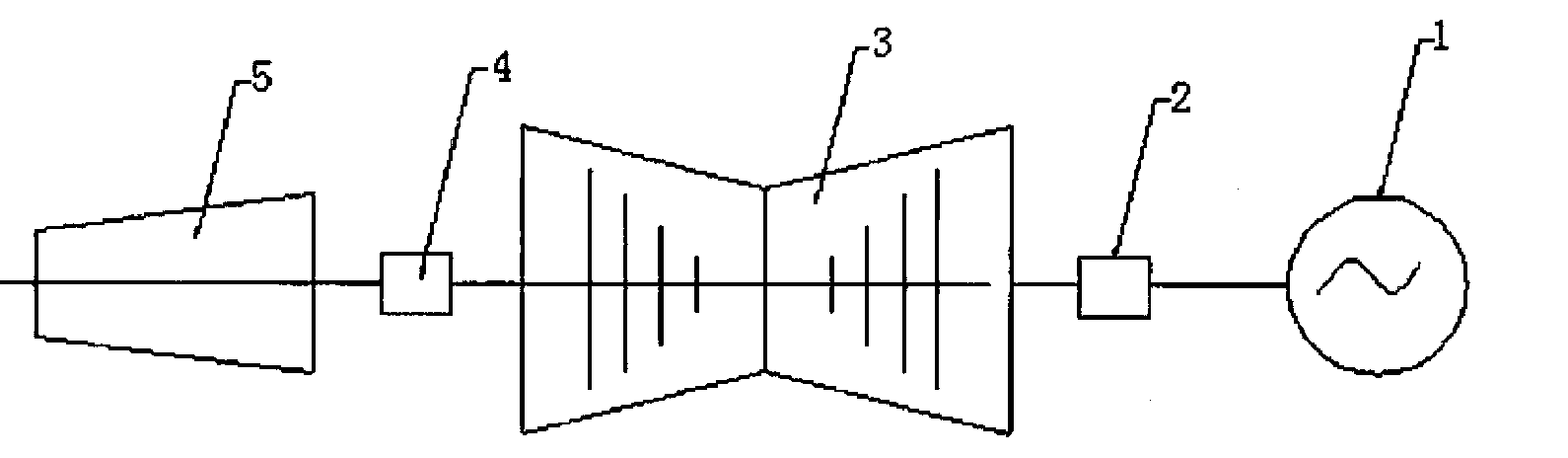

[0054] figure 1It is a schematic diagram of the structure of the invention when it operates with a pure condensing rotor. In the figure, the high and medium pressure rotor 5 of the steam turbine is connected to one end of the low pressure rotor through the second coupling 4, and the other end of the low pressure rotor is connected to the generator 1 through the first coupling 2 for power generation and heating. In non-heating seasons, the low pressure rotor adopts The pure condensing rotor 3 is used for power generation of the unit in the non-heating season. In the heating season, the pure condensing rotor 3 is replaced with the back pressure heating rotor 6 .

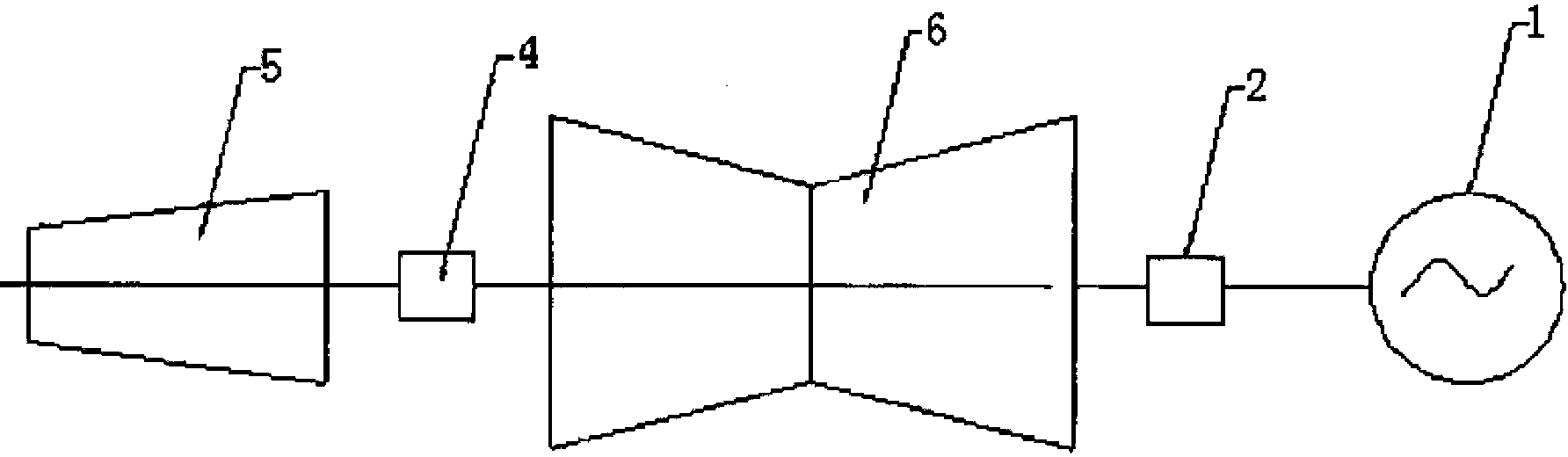

[0055] figure 2 It is a structural schematic diagr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com