Low-rank coal drying method and system

A drying system and drying method technology, applied in the direction of drying solid materials, drying gas arrangement, heating to dry solid materials, etc., can solve the problems of difficult slagging, hidden danger of thermal stability, slagging, etc., and reduce equipment damage. , The effect of improving the utilization rate of exhaust gas and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

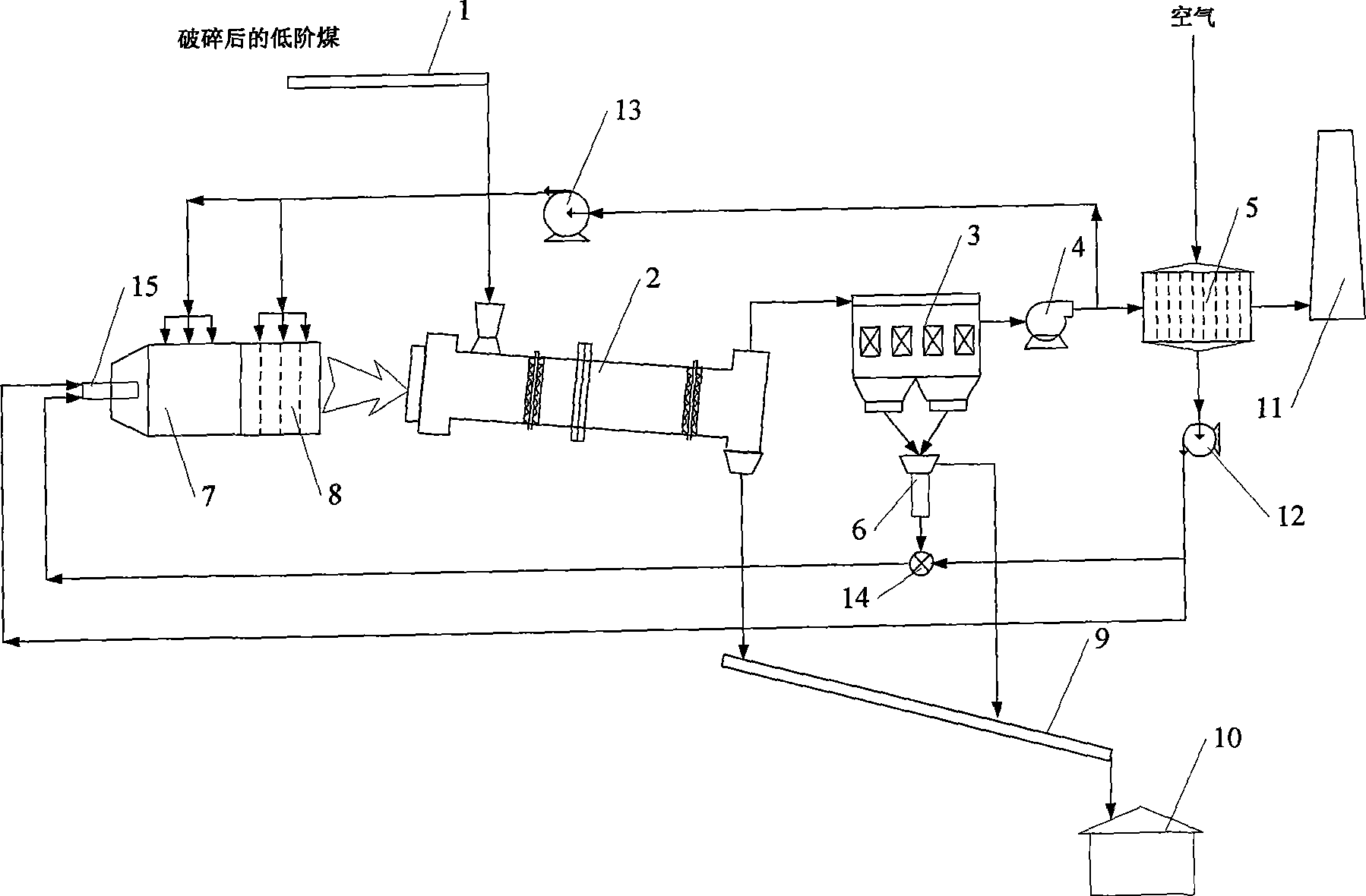

[0057] In order to better illustrate the idea of the present invention, the present invention will be further introduced through the following specific implementation manners in conjunction with the accompanying drawings.

[0058] First, use a crushing device (not shown) to crush the coal into particles, and the particle size of the low-rank coal is preferably between 3 mm and 50 mm. Such as figure 1As shown, the crushed raw low-rank coal is transported to the dryer 2 through the belt conveyor 1 . The low-rank coal sent to the dryer 2 is in direct contact with the hot flue gas from the hot flue gas generator for heat exchange, thereby realizing the drying of the low-rank coal. The dryer can be a rotary drum dryer, or a drying equipment such as an ebullated bed dryer that directly contacts gas and solid for heat exchange.

[0059] The dried low-rank coal coming out of the dryer 2 is transported to the product coal bunker 10 through the belt conveyor 9 for collection.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com