Method for preparing ethylene glycol by ethylene carbonate method

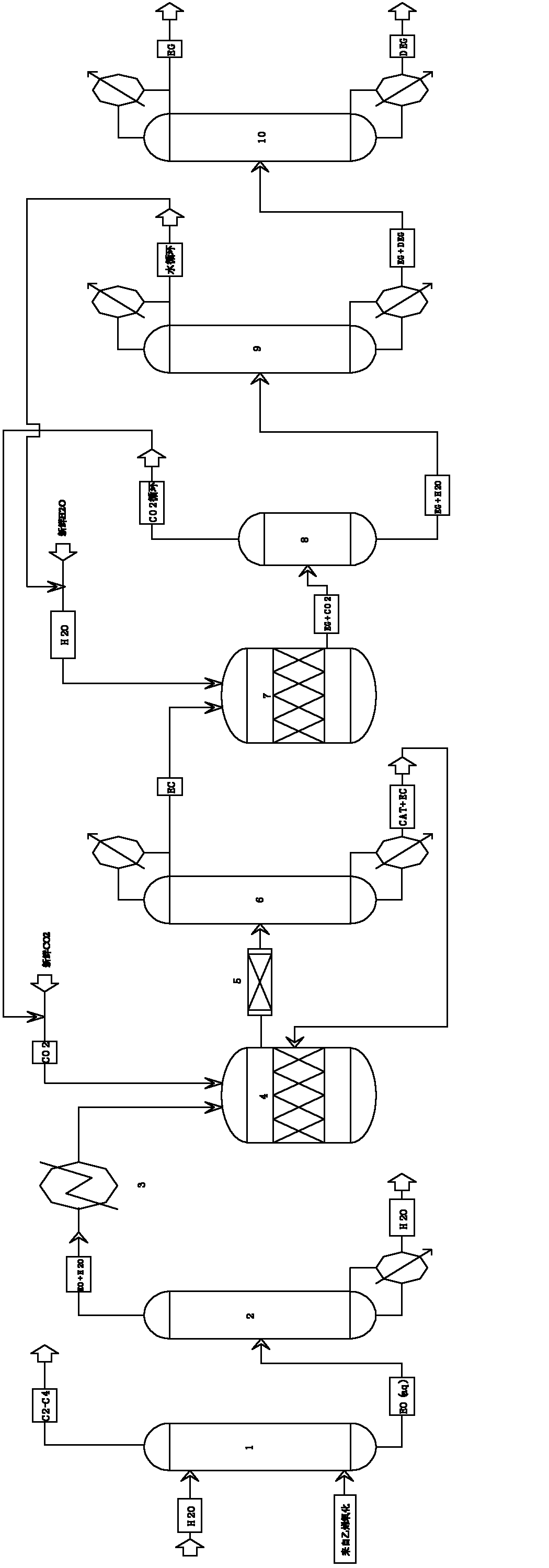

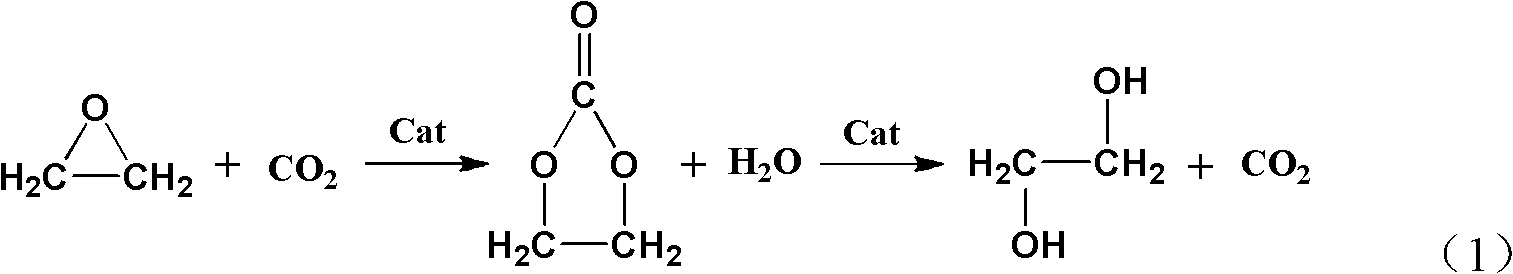

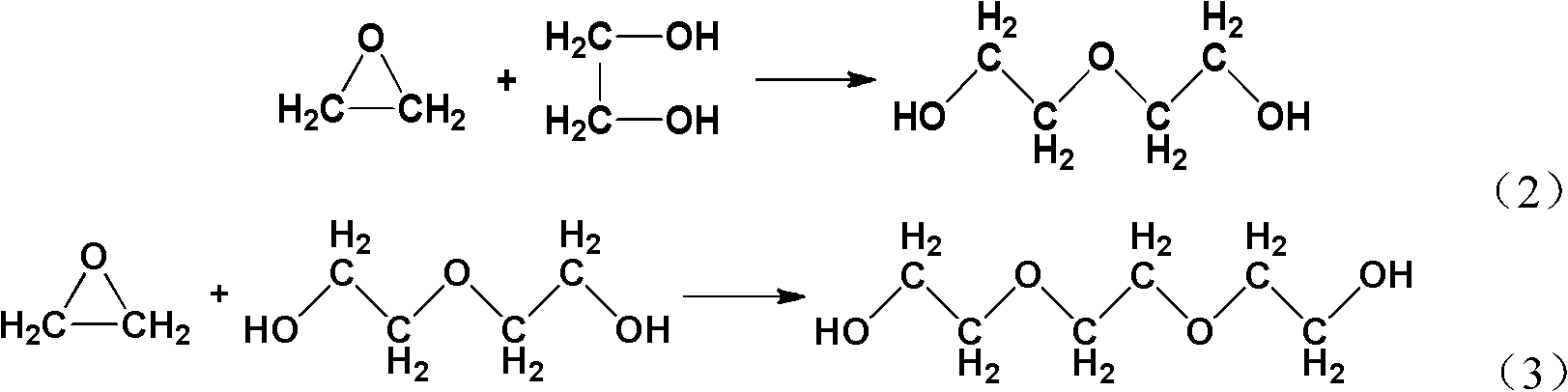

A technology of ethylene carbonate and ethylene glycol is applied in the field of preparing ethylene glycol by ethylene carbonate method, which can solve the problems of unrealized industrial application and the like, and achieve the effects of small pressure fluctuation, high practical feasibility and reduced energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] (1) Treatment of raw material EO

[0064] The ethylene oxidation product enters the cooling and refining unit after being washed with water and desorbed. The EO gas at the top of the tower is condensed from 34°C to 5°C. The total molar mass is 1.81kmol / hr. 2 1.21mol%, H 2 O 4.00mol%, CH 4 0.23mol%, C 2 h 4 0.63mol%, after cooling and refining through a packed tower with 5 theoretical plates, EO-rich liquid with a water content of about 1.7wt% is obtained, the operating pressure is 0.10-0.15MPa, water is basically removed, CH 4 , CO 2 And other insoluble gases are recovered from the top of the tower.

[0065] (2) Esterification reaction process

[0066] The EO-rich liquid obtained by cooling and refining is preheated and mixed with the supplemented circulating metal zinc complex catalyst in a preheating mixer, and then passed into the bubble column reactor, while bubbling CO 2 Recycle gas, the operating temperature is 140°C, the operating pressure is 4MPa, the m...

Embodiment 2

[0074] (1) Preparation of raw material solution

[0075] The ethylene oxidation product enters the cooling and refining unit after being washed with water and desorbed. The EO gas at the top of the tower is condensed from 47°C to 5°C through industrial water and liquid ammonia. The total molar mass is 1.94kmol / hr. 2 1.49mol%, H 2 O 8.28mol%, CH 4 0.30mol%, C 2 h 4 0.76mol%, after cooling and refining through a packed tower with 5 theoretical plates, EO-rich liquid with a water content of about 3.3wt% is obtained, the operating pressure is 0.10-0.15MPa, water is basically removed, CH 4 , CO 2 And other insoluble gases are recovered from the top of the tower.

[0076] (2) Esterification reaction process

[0077] The EO-rich liquid obtained by cooling and refining is preheated and mixed with the supplemented circulating metal zinc complex catalyst in a preheating mixer, and then passed into the bubble column reactor, while bubbling CO 2 Recycle gas, the operating temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com