Method for controlling temperature of reduction rotary kiln by optimizing and adjusting fuel amount and air volume

An air volume control and rotary kiln technology, applied in the field of rotary kiln, can solve the problems of volatile matter and CO escape, the inability to accurately monitor the temperature online and real-time, and the uncoordinated fuel system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

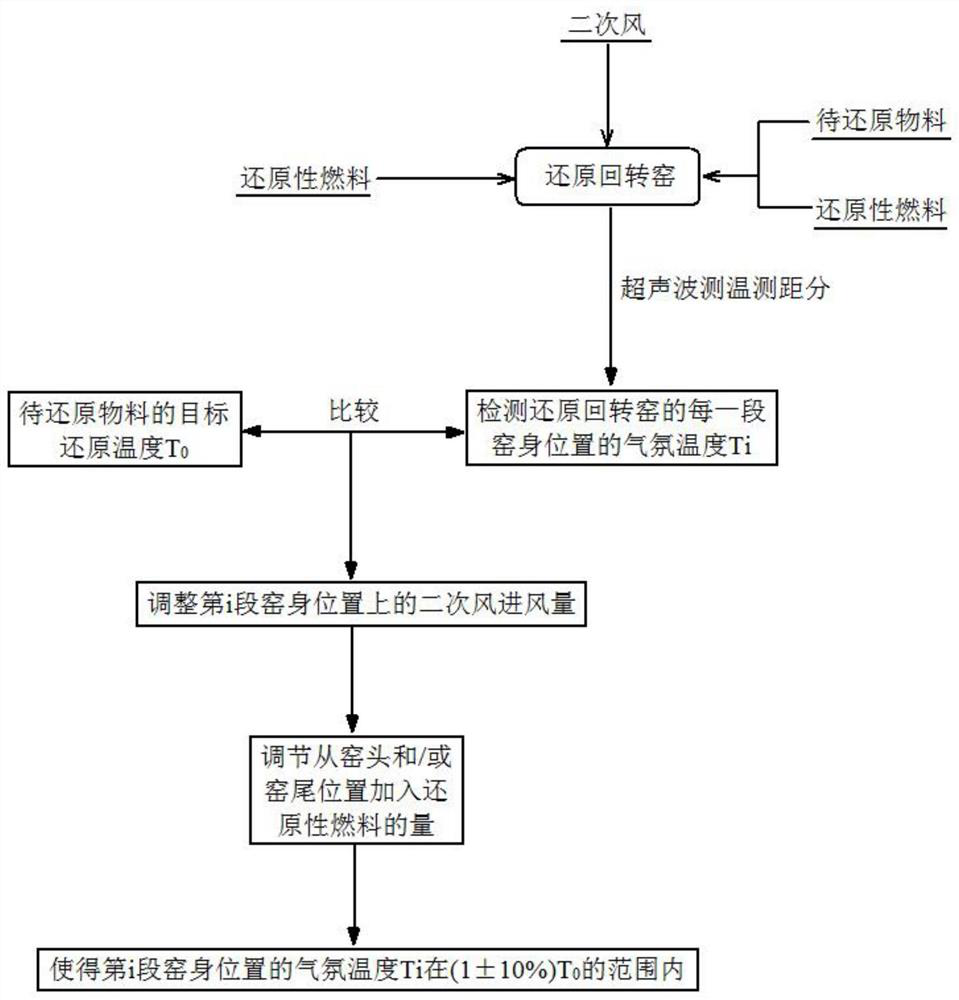

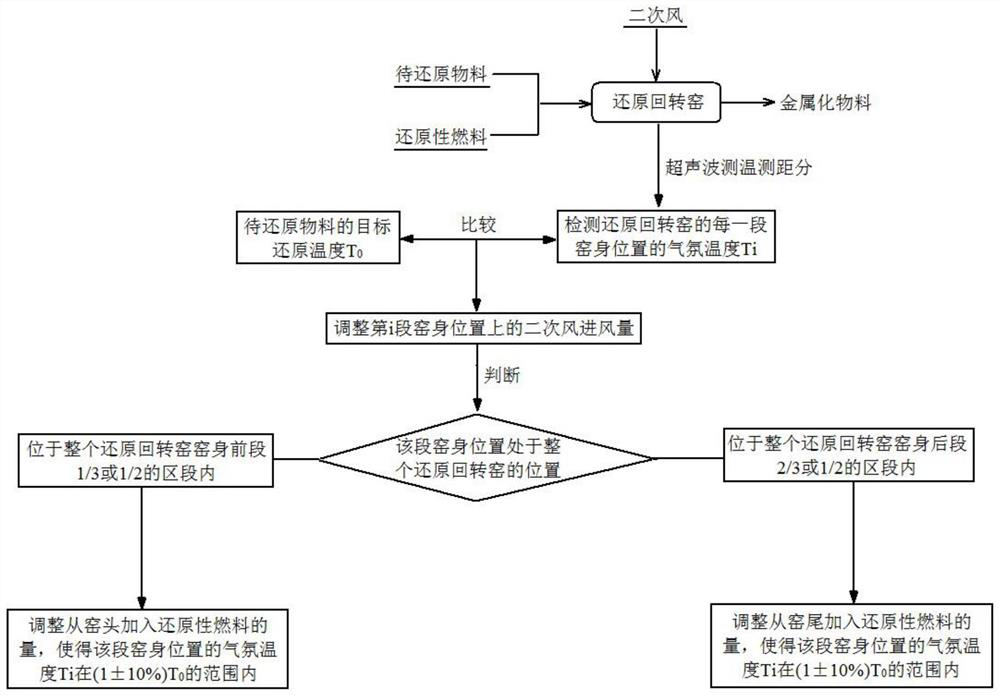

[0178] A method for controlling the temperature of the reduction rotary kiln by optimizing and adjusting the fuel volume and air volume. The reduction rotary kiln 1 is provided with an ultrasonic temperature measurement and distance measuring analyzer 2, and the kiln body of the reduction rotary kiln 1 is divided into n sections, and each section of the kiln body is provided with an ultrasonic temperature measuring and ranging analyzer 2. Secondary air nozzles 3, and each secondary air nozzle 3 is connected to a fan 4. The method includes the following steps:

[0179] 1) Load the material to be reduced into the reduction rotary kiln 1, add reducing fuel at the kiln head 101 and the kiln tail 102 of the reduction rotary kiln 1, and inject secondary air from the secondary air nozzle 3 on each section of the kiln.

[0180] 2) A burner 103 is provided at the position of the kiln head 101 of the reduction rotary kiln 1, and the material to be reduced is burned and reduced by the re...

Embodiment 2

[0190] Repeat Example 1, but compare the target reduction temperature T 0 And the atmospheric temperature Ti at the position of the kiln body of the i-th section is specifically: Calculate the difference between the atmospheric temperature of the kiln body position of the i-th section and the target reduction temperature △E:

[0191] ΔE=T i -T 0 .

Embodiment 3

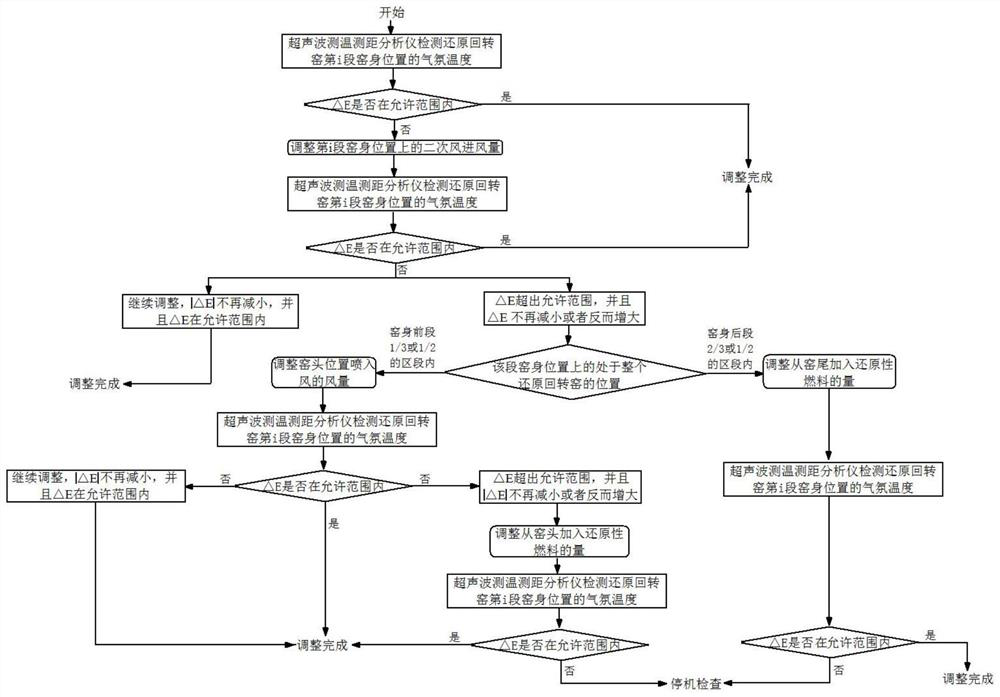

[0193] Repeat Example 2, except that step 5) is specifically:

[0194] 5a) Adjust the fan 4 connected to the secondary air nozzle 3 on the kiln body position of the i-th section, so as to adjust the secondary air intake air volume on the kiln body position of the i-th section.

[0195] 5b) The ultrasonic temperature measurement and distance analyzer 2 detects the atmospheric temperature Ti at the position of the kiln body in this section of the reduction rotary kiln 1 again, and compares the target reduction temperature T 0 The difference ΔE is obtained from the adjusted atmospheric temperature Ti at the kiln body position of the i-th section.

[0196] To analyze and compare:

[0197] 5b1) If the difference △E between the atmospheric temperature at the position of the kiln body and the target reduction temperature is within the range of ±10°C after adjusting the secondary air intake air volume at the position of the kiln body, the current secondary air intake is maintained in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com