Method for achieving defluorination and recycling of secondary aluminum ash with series-parallel method

A technology of secondary aluminum and mixed connection method, which is applied in the direction of solid waste removal, etc., can solve problems such as danger, high energy consumption, and acid waste water cannot be recycled, and achieve the effect of reducing equipment corrosion and solving circulation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

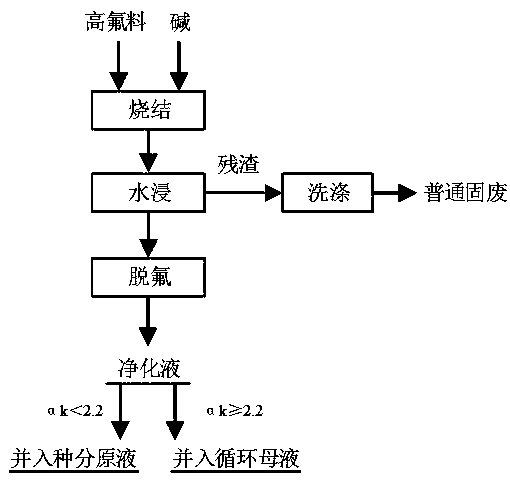

Image

Examples

Embodiment 1

[0023] The hybrid method of this embodiment realizes the method of secondary aluminum ash defluorination and resource utilization, and the steps are as follows:

[0024] Take 50 g of high-fluorine secondary aluminum ash with a particle size of less than 150 μm as the raw material, see Table 1 for the chemical composition, add 37.65 g of solid sodium hydroxide (soda-ash ratio 0.75:1), mix well and sinter at 800 °C for 2 h , the fluorine in aluminum ash is represented by SiF 4 Volatile form, absorbed by sodium hydroxide solution.

[0025] The sintered clinker was leached with an aqueous solution, the liquid-solid ratio was controlled at 4:1, the leaching temperature was 80 °C, and the leaching time was 2 h. The obtained eluate composition was: Al 2 o 3 =81.73g / L, Na 2 o k =86.49g / L, caustic ratio αk=1.74. After adding calcium oxide and stirring for defluorination, the solution can be used as a seed solution and incorporated into the Bayer system for processing low-fluorine ...

Embodiment 2

[0029] The hybrid method of this embodiment realizes the method of secondary aluminum ash defluorination and resource utilization, and the steps are as follows:

[0030] Take 50 g of high-fluorine secondary aluminum ash with a particle size of less than 150 μm as the raw material. The chemical composition is shown in Table 2. Add 67.37 g of solid sodium carbonate (soda-to-ash ratio 1.347:1), mix well and sinter at 900 °C for 2 h. Fluorine in aluminum ash is SiF 4 Volatile form, absorbed by sodium carbonate solution.

[0031] The sintered clinker is leached with an aqueous solution, the liquid-solid ratio is controlled at 5:1, the leaching temperature is 90 °C, and the leaching time is 2 h. The obtained leaching liquid composition is: Al 2 o 3 =43.38 g / L, Na 2 o k =77.62 g / L, caustic ratio αk=3.83. After adding calcium oxide and stirring for defluorination, the solution can be used as a circulating mother liquor and incorporated into the Bayer system for processing low-flu...

Embodiment 3

[0035] The hybrid method of this embodiment realizes the method of secondary aluminum ash defluorination and resource utilization, and the steps are as follows:

[0036] Take 50 g of high-fluorine secondary aluminum ash with a particle size of less than 150 μm as the raw material. The chemical composition is shown in Table 3. Add 50 g of solid sodium hydroxide (soda-ash ratio 1:1), mix well and sinter at 800 °C for 2 h. Fluorine in aluminum ash is SiF 4 Volatile form, absorbed by sodium hydroxide solution.

[0037] The sintered clinker is leached with an aqueous solution, the liquid-solid ratio is controlled at 5:1, the leaching temperature is 80 °C, and the leaching time is 2 h. The obtained leaching liquid composition is: Al 2 o 3 =77.21 g / L, Na 2 o k =51.13 g / L, caustic ratio αk=1.47. After adding calcium hydroxide and stirring for defluorination, the solution can be used as a seed solution and incorporated into the Bayer system for processing low-fluorine materials to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com