Fine sand screening device capable of automatically discharging coarse sand

A technology of automatic discharge and screening device, applied in the direction of filter screen, solid separation, grille, etc., can solve the problem of inability to discharge coarse sand, and achieve easy disassembly, replacement or maintenance, good sand screening effect, and sand screening efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

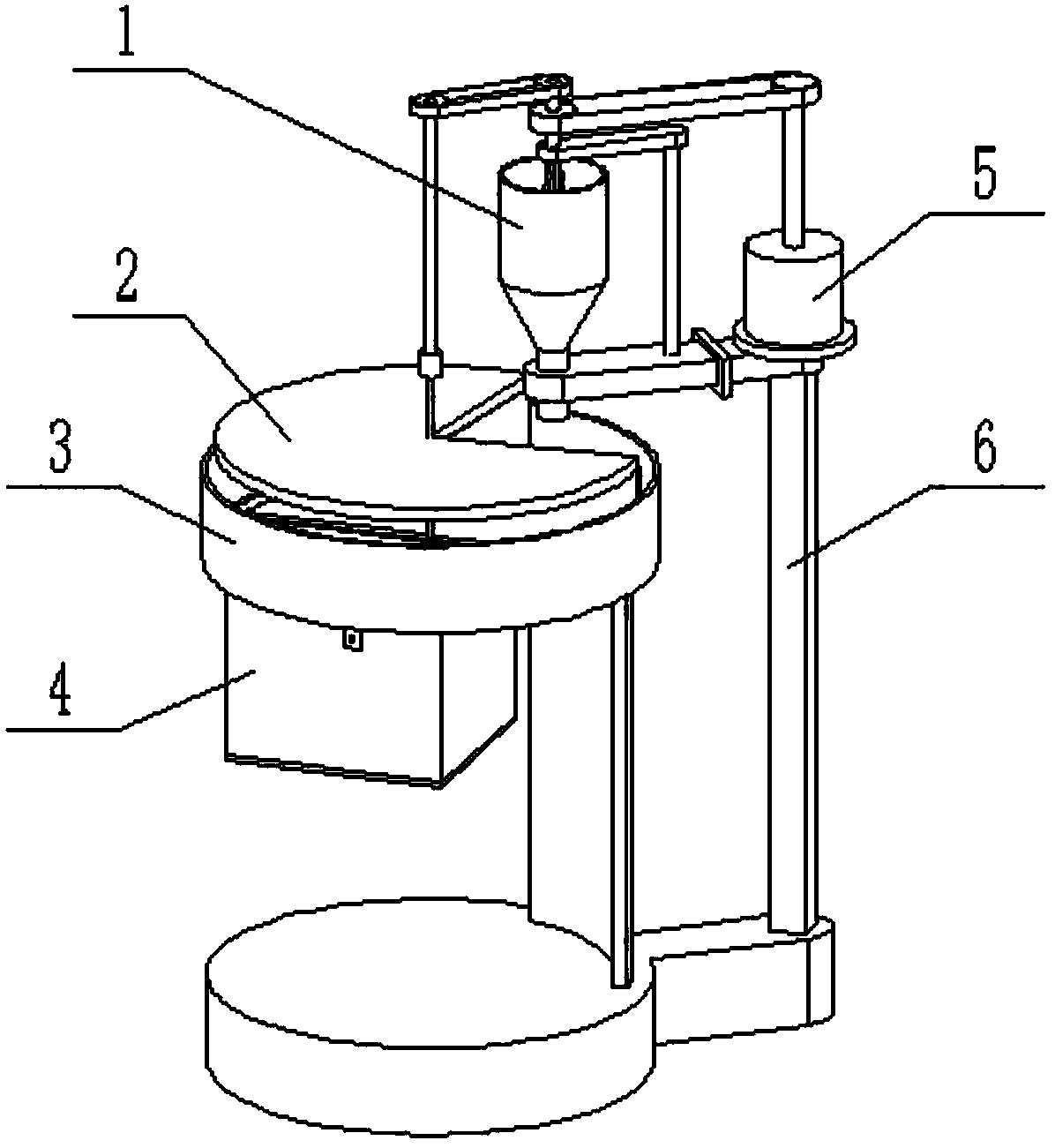

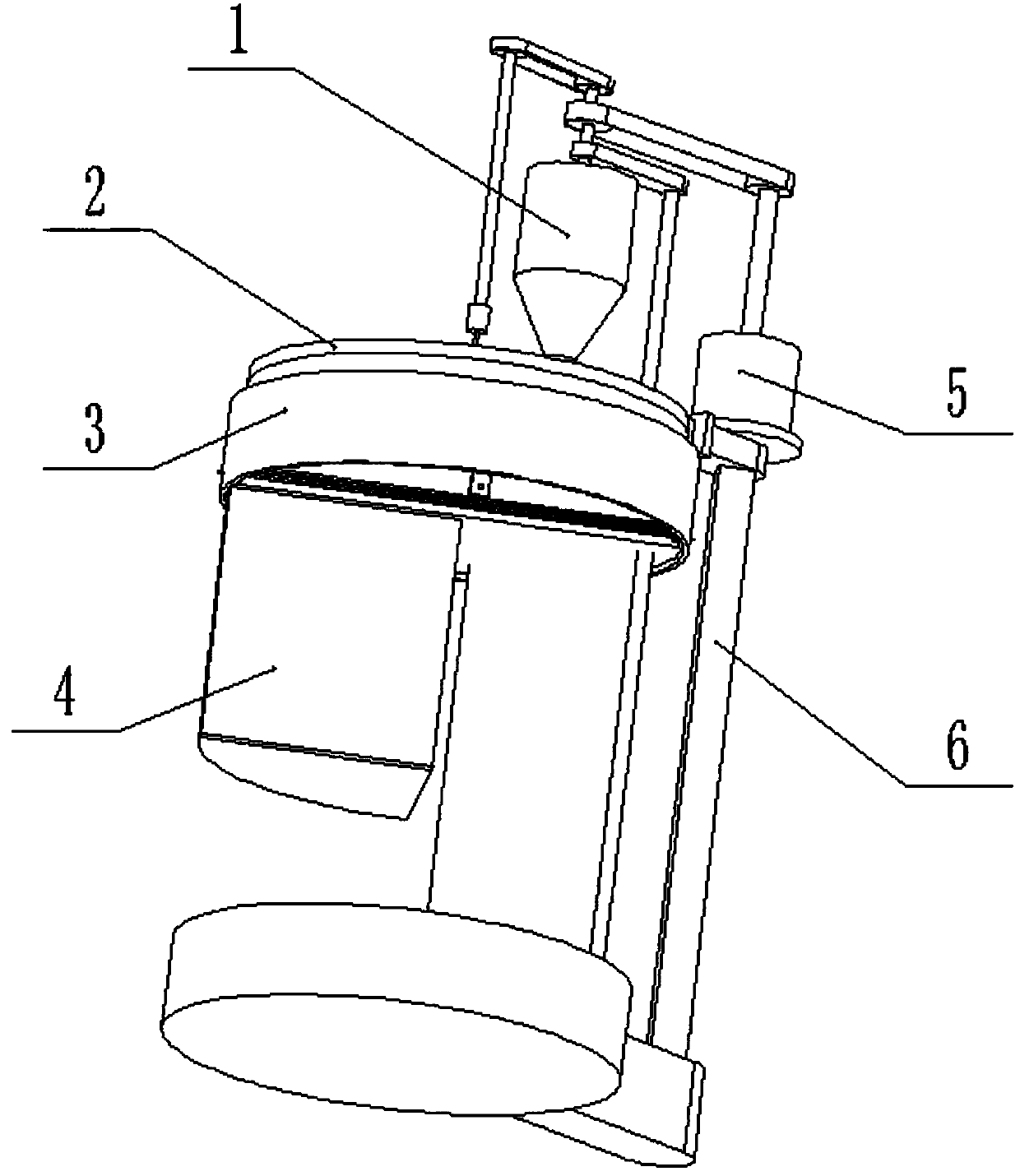

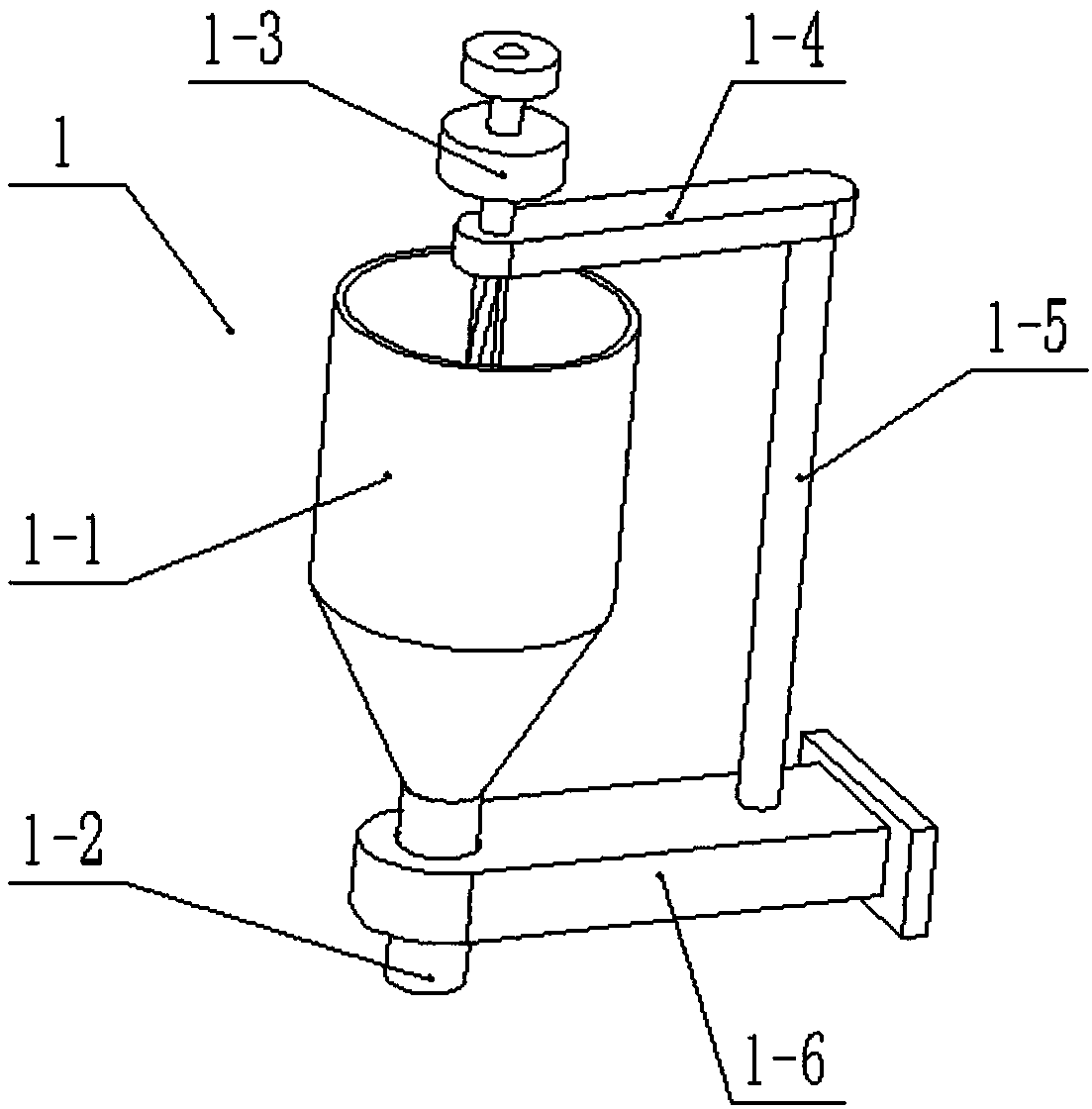

[0033] A fine sand screening device capable of automatically discharging coarse sand, comprising a sand inlet cylinder assembly 1, a rotating disk assembly 2, a sand screening assembly 3, a coarse sand collection assembly 4, a sand screening drive assembly 5 and a mounting frame assembly 6, the present invention A fine sand screening device that can automatically discharge coarse sand, its working principle is: when in use, first connect the sand screening drive assembly 5 to the power supply and turn it on through the control switch, and then pour it into the sand inlet assembly 1 Enter the sand that needs to be screened. After the sand falls into the sand screen assembly 3 through the sand inlet tube assembly 1, it will move clockwise under the drive of the rotating disc assembly 2, and the fine sand will be screened through the sand screening assembly 3. After the fine sand is sieved, the remaining coarse sand falls into the inside of the coarse sand collection assembly 4, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com