Micro spouted bed gas-solid reaction kinetic analysis device and analysis method

A technology of kinetic analysis and gas-solid reaction, applied in measuring devices, analytical materials, thermal analysis of materials, etc., can solve problems such as temperature deviation, difficulty in uniquely determining the reaction model function, and the inability to test the reaction characteristics of unstable substances, etc., to achieve small Minimize impact, achieve continuity and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

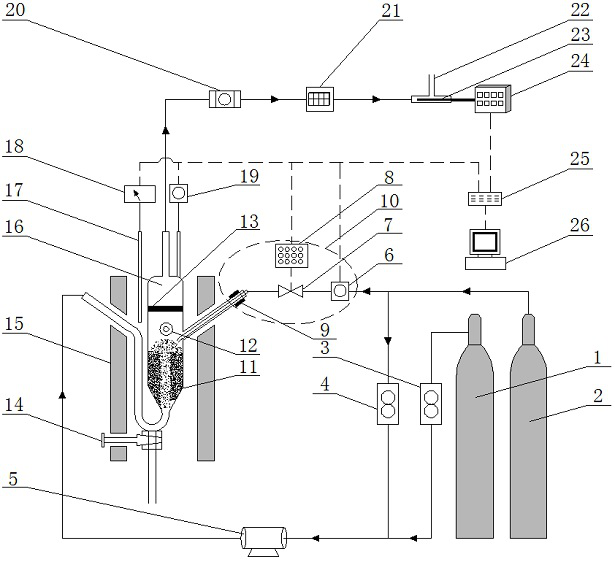

[0026] see figure 1 A micro-spouted bed gas-solid reaction kinetics analysis device includes a pulse sampling device 10, an isothermal reaction generating device, a gas circuit device and an online gas analysis and testing device.

[0027] The pulse sampling device 10 comprises a first pressure sensor 6, a solenoid valve 7, a programmable logic controller 8 and a feeder 9; the first pressure sensor 6 and the programmable logic controller 8 are all connected to the solenoid valve 7, and the solenoid valve 7 is connected to the feeder. The inlet of the feeder 9 is connected, and the outlet of the feeder 9 extends into the micro-spouted bed 16 to ensure that the pulsed sample can be quickly mixed with the flow medium p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com